High-concentration negative oxygen ion powder and preparation method thereof

A negative oxygen ion powder, high-concentration technology, applied in separation methods, chemical instruments and methods, other chemical processes, etc., can solve the problems of single function and insufficient powder contact, and achieve uniform particles, good adsorption capacity, good The effect of air purifying ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

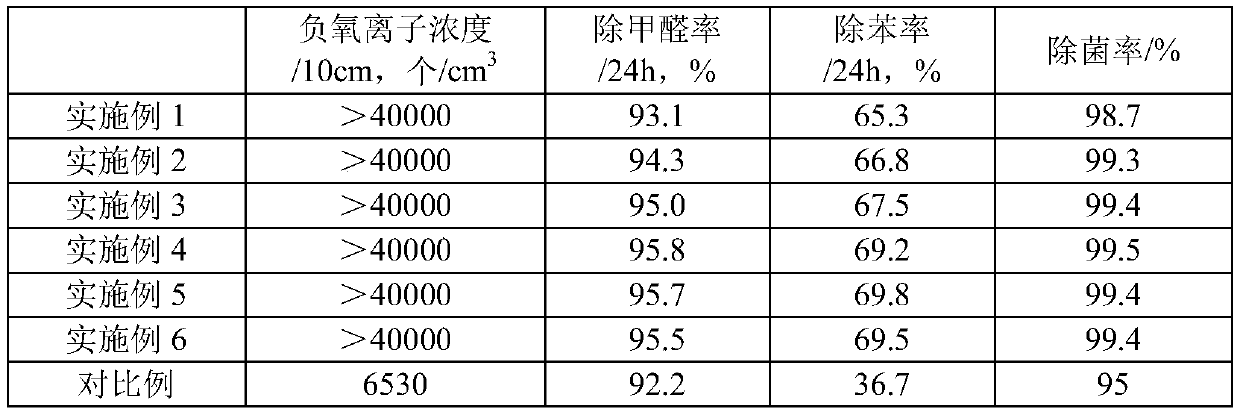

Examples

preparation example Construction

[0034] The preparation method of high-concentration negative oxygen ion powder of the present invention comprises the following steps: 1) raw stone powder is added in the calcium suspension and mixed uniformly, then feeds carbon dioxide gas to react for 30-50s to obtain an acidification system; the calcium suspension is Calcium hydroxide suspension; 2) Add crystal form regulator and catalytic substance to the acidification system obtained in step 1) and mix uniformly, and pass through carbon dioxide for 10-15min to obtain a regulating system; the catalytic substance is Au / TiO 2 The composite catalyst may be composed of a gold source and a titanium source; 3) adding a dispersant to the adjustment system obtained in step 2) and mixing evenly to obtain a homodisperse system, separating solid and liquid, and drying to obtain.

[0035] The rough stone powder can be the rough stone powder in the prior art. Preferably, the rough stone powder is at least one of tourmaline powder, medic...

Embodiment 1

[0045] The preparation method of the high-concentration negative oxygen ion powder of the present embodiment comprises the steps:

[0046] 1) Add 45g of calcium hydroxide to 500mL of deionized water, stir and mix evenly to obtain a calcium hydroxide suspension, place the suspension in a water bath at 40°C, add 40g of raw stone powder with an average particle size of 50nm into calcium hydroxide for suspension In the solution, stir and mix evenly at a speed of 200rpm, then continue to stir at the same speed and pass in carbon dioxide gas at a flow rate of 1L / min for 50s to obtain an acidification system; the raw stone powder is tourmaline powder;

[0047] 2) Add 5g of crystal form modifier to the acidified system obtained in step 1), stir and mix evenly, then add 0.5g of Au / TiO 2 Composite catalyst, under stirring at a rotating speed of 80rpm, carbon dioxide gas is introduced into a regulating system at a flow rate of 5L / min for 15min; the crystal form regulator is citric acid; ...

Embodiment 2

[0050] The preparation method of the high-concentration negative oxygen ion powder of the present embodiment comprises the steps:

[0051] 1) Add 20g of calcium hydroxide to 500mL of deionized water, stir and mix evenly to prepare calcium hydroxide suspension, place the suspension in a water bath at 50°C, add 45g of raw stone powder with an average particle size of 100nm into calcium hydroxide for suspension In the solution, stir and mix evenly at a speed of 150rpm, then continue to stir at the same speed and pass in carbon dioxide gas for 30s at a flow rate of 2L / min to obtain an acidification system; the raw stone powder is tourmaline powder;

[0052] 2) Add 10 g of crystal form modifier to the acidified system obtained in step 1), stir and mix evenly, then add 1 g of Au / TiO 2 Composite catalyst, under stirring at a rotating speed of 50rpm, carbon dioxide gas is introduced into a regulating system at a flow rate of 10L / min for 10min to obtain an adjustment system; the crysta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com