Vacuum plastic uptake adhesive with high peel strength and preparation method thereof

A technology of vacuum suction and high peeling, applied in the field of plastic suction, can solve the problem of low peel strength, and achieve the effect of improving peel strength, reducing dependence and low impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

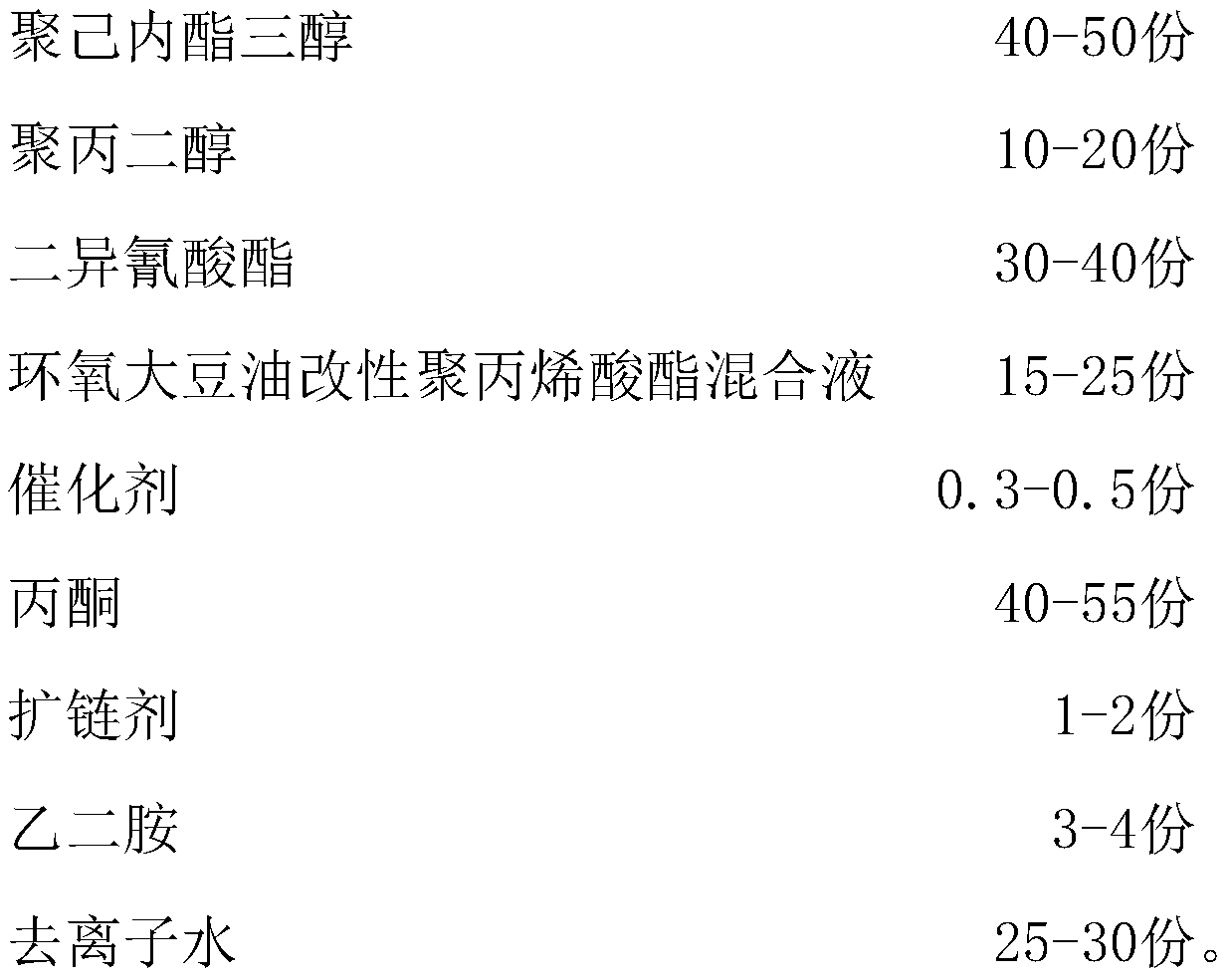

[0032] A preparation method of vacuum-absorbing plastic with high peel strength, comprising the steps of:

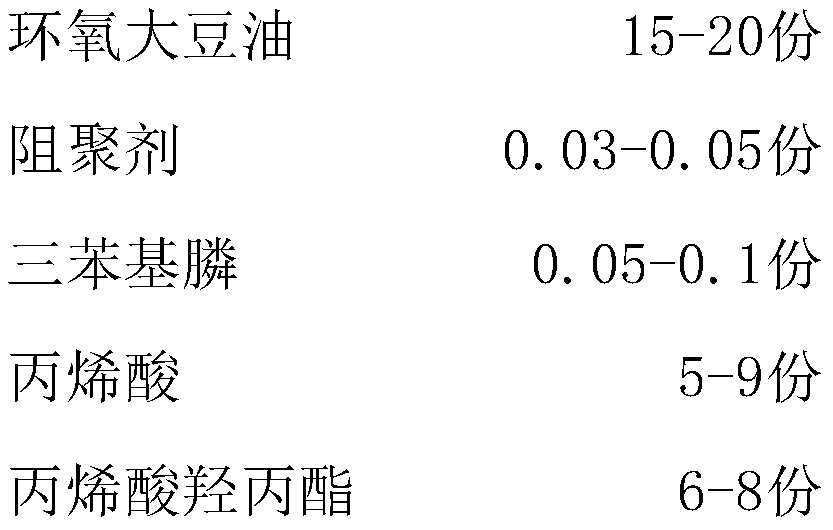

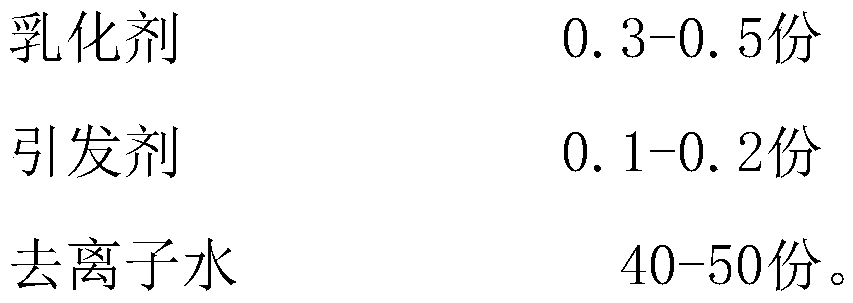

[0033] (1) Add 17.5 parts by weight of epoxidized soybean oil, 0.04 parts by weight of polymerization inhibitor and 0.07 parts by weight of triphenylphosphine in the reactor, heat up to 87 ° C, and slowly add 3 parts by weight of Acrylic acid, then heated up to 115°C, reacted for 6.8h, and then distilled under reduced pressure to obtain epoxy soybean oil acrylate;

[0034] (2) Get the epoxidized soybean oil acrylate obtained in step (1), 4 parts by weight of acrylic acid, 7 parts by weight of hydroxypropyl acrylate, and 0.4 parts by weight of emulsifier, add to 45 parts by weight of deionized water, after stirring, Add 0.15 parts by weight of an initiator, raise the temperature to 88° C., and react for 1.6 hours to obtain an epoxy soybean oil-modified polyacrylate mixed solution;

[0035] (3) Add 45 parts by weight of polycaprolactone triol, 15 parts by weight of polypr...

Embodiment 2

[0043] A preparation method of vacuum-absorbing plastic with high peel strength, comprising the steps of:

[0044] (1) Add 15 parts by weight of epoxidized soybean oil, 0.03 parts by weight of polymerization inhibitor and 0.05 parts by weight of triphenylphosphine in the reactor, raise the temperature to 85 ° C, and slowly add 2 parts by weight of Acrylic acid, then heated up to 110°C, reacted for 6.5h, and then distilled under reduced pressure to obtain epoxy soybean oil acrylate;

[0045] (2) Get the epoxidized soybean oil acrylate obtained in step (1), 3 parts by weight of acrylic acid, 6 parts by weight of hydroxypropyl acrylate, and 0.3 parts by weight of emulsifier, and add them to 40 parts by weight of deionized water, after stirring evenly, Add 0.1 parts by weight of an initiator, raise the temperature to 85° C., and react for 1.5 hours to obtain an epoxy soybean oil-modified polyacrylate mixed solution;

[0046] (3) Add 40 parts by weight of polycaprolactone triol, 1...

Embodiment 3

[0054] A preparation method of vacuum-absorbing plastic with high peel strength, comprising the steps of:

[0055] (1) Add 20 parts by weight of epoxidized soybean oil, 0.05 parts by weight of a polymerization inhibitor and 0.1 parts by weight of triphenylphosphine in the reactor, raise the temperature to 90°C, and slowly add 4 parts by weight of Acrylic acid, then heated up to 120°C, reacted for 7h, and then distilled under reduced pressure to obtain epoxy soybean oil acrylate;

[0056] (2) Get the epoxy soybean oil acrylate obtained in step (1), 5 parts by weight of acrylic acid, 8 parts by weight of hydroxypropyl acrylate, and 0.5 parts by weight of emulsifier, and add them to 50 parts by weight of deionized water, after stirring evenly, Add 0.2 parts by weight of an initiator, raise the temperature to 90°C, and react for 2 hours to obtain a mixed solution of epoxy soybean oil-modified polyacrylate;

[0057] (3) Add 50 parts by weight of polycaprolactone triol, 20 parts by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com