Preparation method of high-transparency self-adhesive PBAT preservative film

A fresh-keeping film and transparent technology, applied in the polymer field, can solve problems such as white pollution, achieve the effect of improving anti-fogging, simplifying production process, and accelerating molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

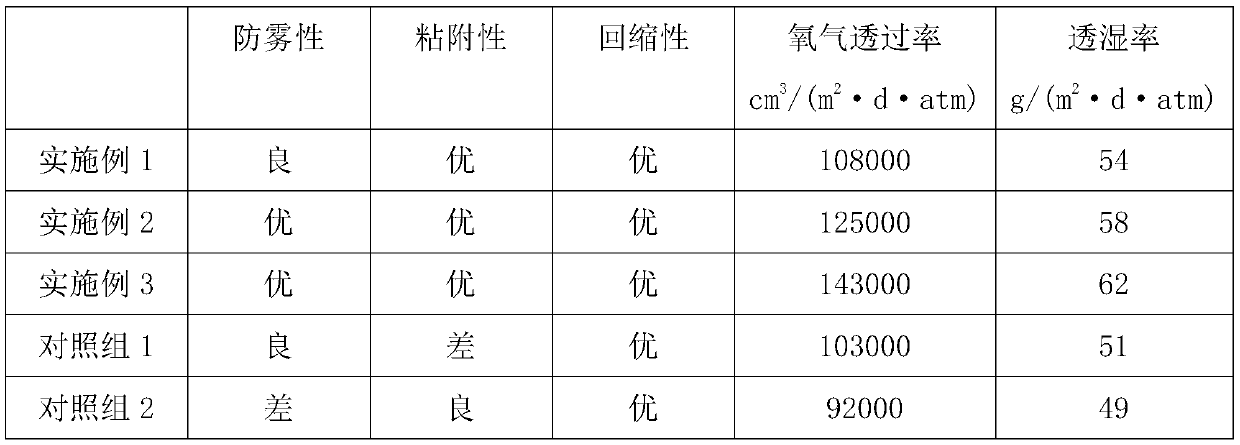

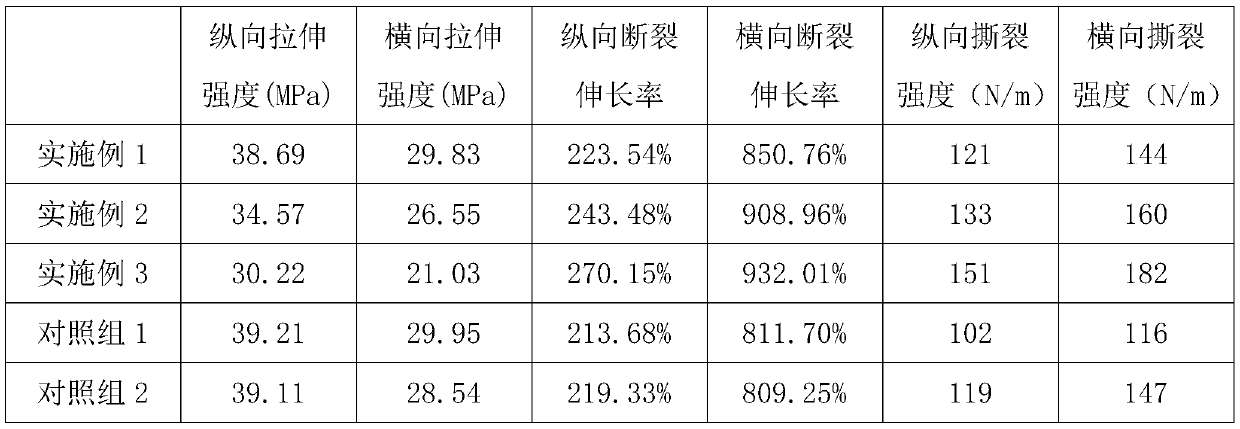

Examples

Embodiment 1

[0021] This embodiment discloses a method for preparing a highly transparent self-adhesive PBAT preservative film, comprising the following steps:

[0022] S1. In terms of parts by weight, add 95.5 parts of PBAT and 3 parts of ACR into the high-speed mixer, stir at 200r / min, then slowly add 0.5 parts of glycerin and stir at 200r / min for two minutes, then add 2 Parts of fatty acid esters of glycerol were stirred for 3 min at a rotating speed of 200r / min to obtain a homogeneously mixed material.

[0023] S2. Put the mixed material into a twin-screw extruder with a length-to-diameter ratio of 52:1, and obtain pellets for making plastic wrap after extrusion, stripping, cooling, and pelletizing; twin-screw extruder barrel The temperature was 150°C and the die temperature was 160°C.

[0024] S3. Put the obtained pellets into a film blowing machine, and obtain a highly transparent self-adhesive PBAT preservative film through extrusion, inflation, traction, cooling, and winding. The ...

Embodiment 2

[0028] This embodiment discloses a method for preparing a highly transparent self-adhesive PBAT preservative film, comprising the following steps:

[0029] S1. In terms of parts by weight, add 92.2 parts of PBAT and 5 parts of ACR into the high-speed mixer, stir at 200r / min, then slowly add 0.8 parts of glycerin, stir at 200r / min for 2min, then add 2 Parts of fatty acid esters of glycerol were stirred for 3 min at a rotating speed of 200r / min to obtain a homogeneously mixed material.

[0030] S2. Put the mixed material into a twin-screw extruder with a length-to-diameter ratio of 52:1, and obtain pellets for making plastic wrap after extrusion, stripping, cooling, and pelletizing; twin-screw extruder barrel The temperature was 140°C and the die temperature was 155°C.

[0031] S3. Put the obtained pellets into a film blowing machine, and obtain a highly transparent self-adhesive PBAT preservative film through extrusion, inflation, traction, cooling, and winding. The barrel tem...

Embodiment 3

[0034] This embodiment discloses a method for preparing a highly transparent self-adhesive PBAT preservative film, comprising the following steps:

[0035] S1. In terms of parts by weight, add 88 parts of PBAT and 8 parts of ACR into the high-speed mixer, stir at 200r / min, then slowly add 1 part of glycerin, stir at 200r / min for 2min, then add 3 Parts of fatty acid esters of glycerol were stirred for 3 min at a rotating speed of 200r / min to obtain a homogeneously mixed material.

[0036] S2. Put the mixed material into a twin-screw extruder with a length-to-diameter ratio of 52:1, and obtain pellets for making plastic wrap after extrusion, stripping, cooling, and pelletizing; twin-screw extruder barrel The temperature was 155°C and the die temperature was 170°C.

[0037] S3. Put the obtained pellets into a film blowing machine, and obtain a highly transparent self-adhesive PBAT preservative film through extrusion, inflation, traction, cooling, and winding. The barrel temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com