Environment-friendly trivalent cobalt-free color passivation solution for zinc layer, and passivation process

An environmentally friendly, trivalent chromium technology, applied in the coating process of metal materials, etc., can solve the problems of accelerated passivation, poor corrosion resistance, and environmental hazards, achieving good stability and durability, and a bright and durable appearance , The process is easy to control the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

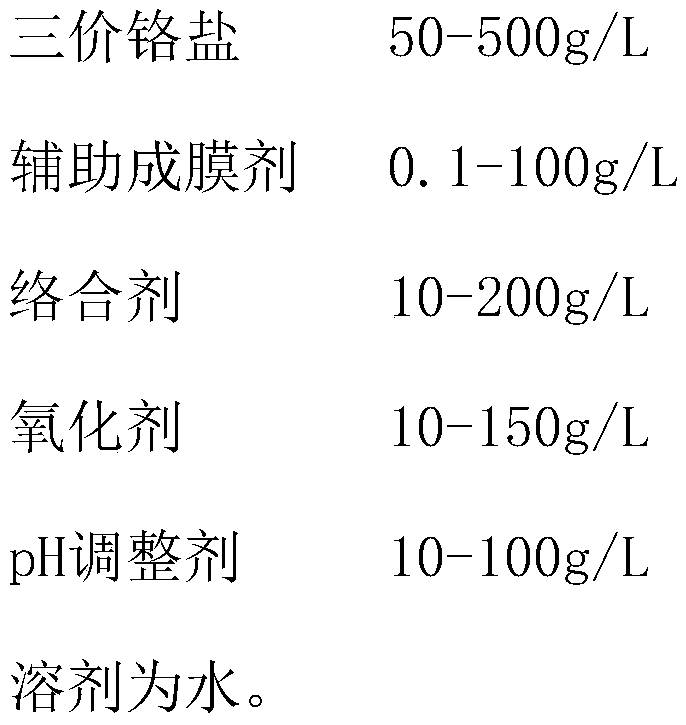

[0025] Embodiment 1: A kind of environment-friendly trivalent chromium cobalt-free color passivation solution and technology for zinc layer

[0026]

[0027] Using the trivalent chromium color passivation agent of this embodiment, the pH of the passivation solution is 2.1, the passivation temperature is 25° C., and the passivation time is 60 s, a bright yellow-green color passivation film is obtained.

Embodiment 2

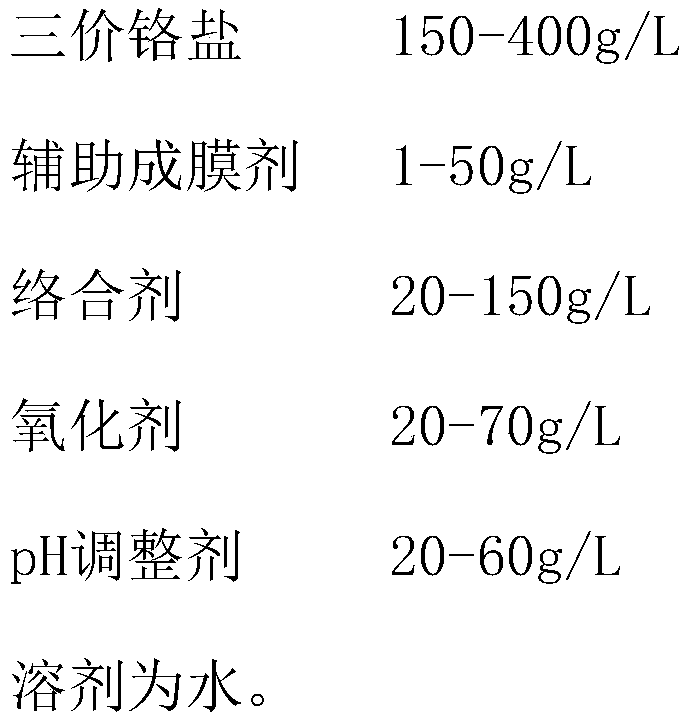

[0028] Embodiment 2: A kind of environment-friendly trivalent chromium cobalt-free color passivation solution and technology for zinc layer

[0029]

[0030]

[0031] Using the trivalent chromium color passivation agent of this embodiment, the pH of the passivation solution is 2.9, the passivation temperature is 25° C., and the passivation time is 40 s to obtain a bright red and green color passivation film.

Embodiment 3

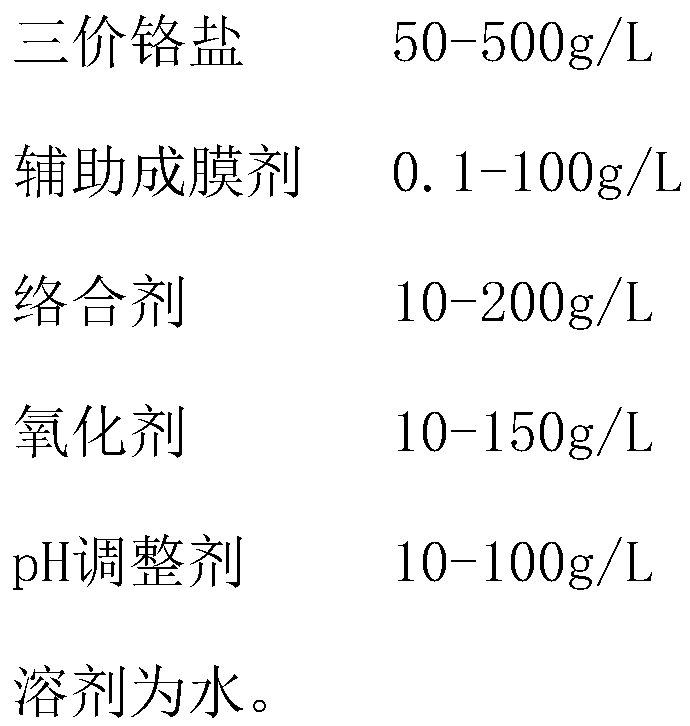

[0032] Embodiment 3: A kind of environment-friendly trivalent chromium cobalt-free color passivation solution and technology for zinc layer

[0033]

[0034] Using the trivalent chromium color passivation agent of this embodiment, the pH of the passivation solution is 1.8, the passivation temperature is 28° C., and the passivation time is 50 s to obtain a yellow-green color passivation film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com