Electroplating method, device and equipment and storage medium

A technology of electroplating tank and plating solution, which is applied in the direction of electrolysis process, electrolysis components, cells, etc., and can solve problems such as the decrease of the bonding force between the coating layer and the workpiece, the effect is not very ideal, the stability of the electroplating quality, and the difficulty in satisfying the electroplating of workpieces with high requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

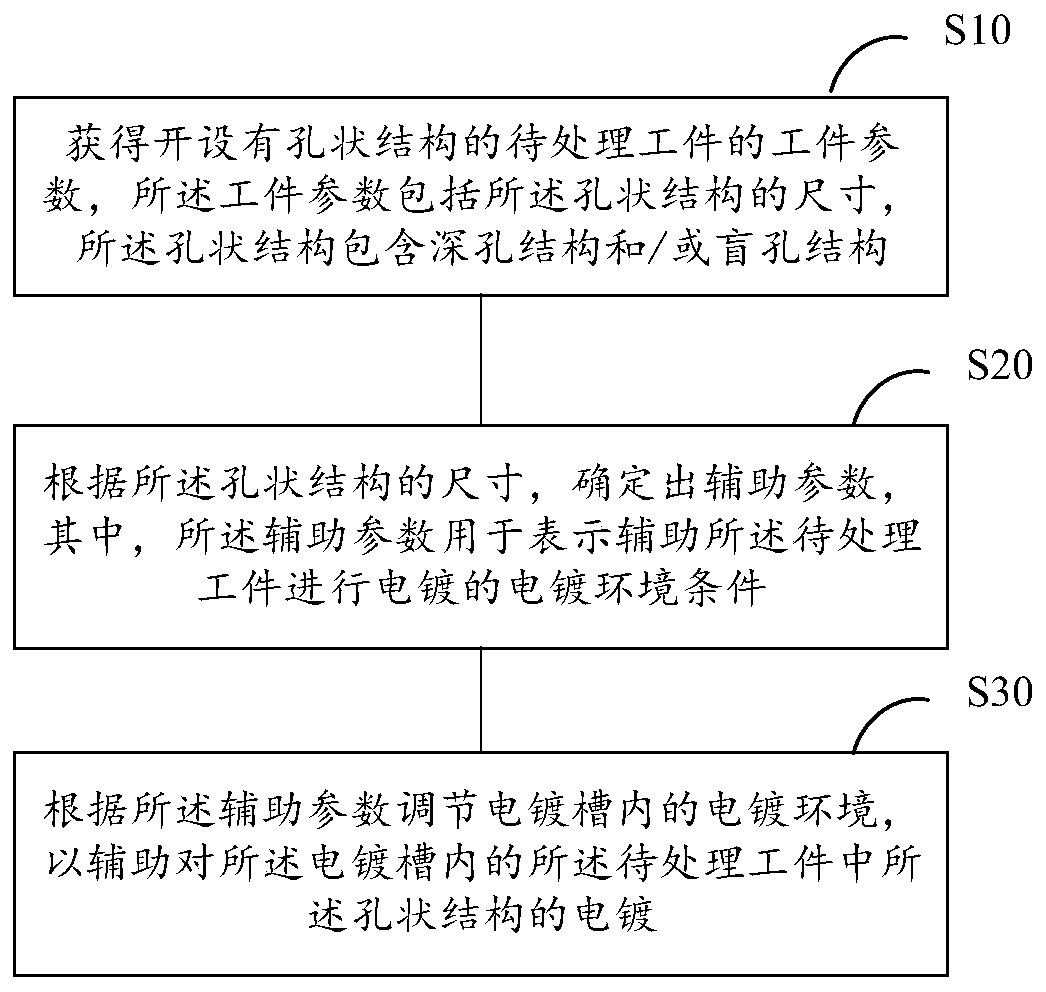

[0030] The technical solutions in the embodiments of the present application will be described below with reference to the drawings in the embodiments of the present application.

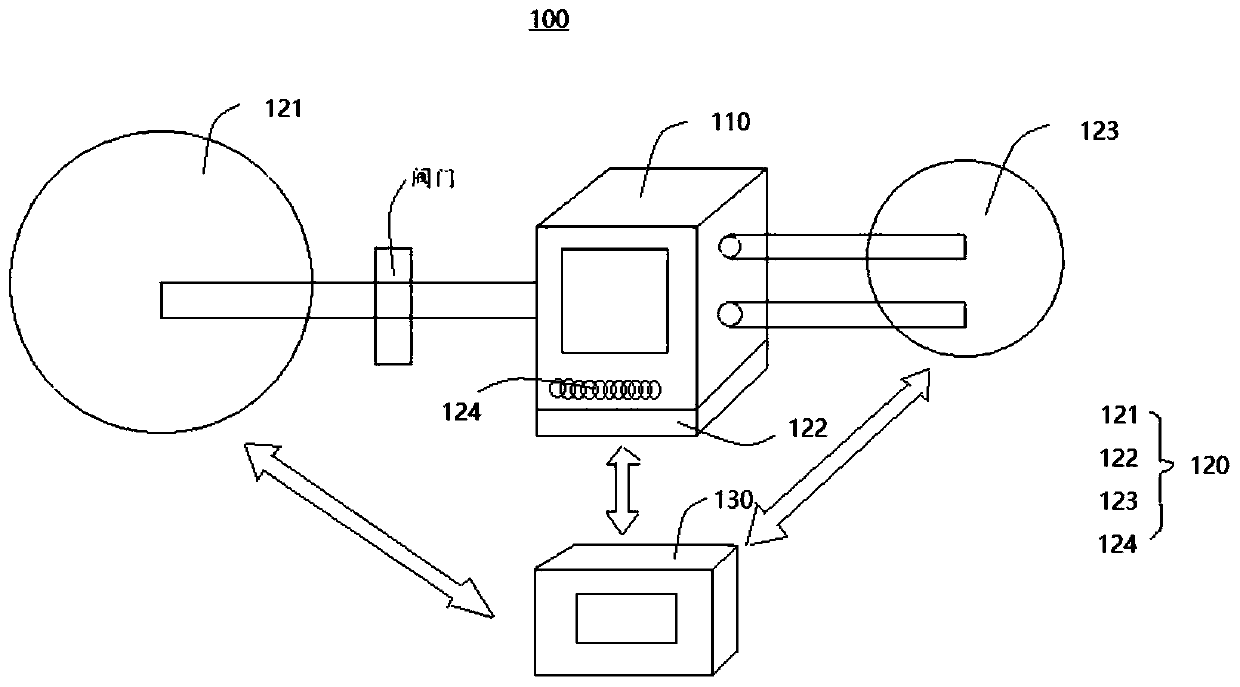

[0031] see figure 1 , figure 1 It is a schematic diagram of an electroplating equipment 100 provided in the embodiment of the present application.

[0032] In this embodiment, the electroplating equipment 100 can include an electroplating tank 110 and an auxiliary device 120, wherein the electroplating tank 110 can be used to accommodate the plating solution and the workpiece to be processed, and the auxiliary device 120 can regulate the electroplating environment in the electroplating tank 110 ( Such as temperature, pressure, bath flow rate, etc.).

[0033] Exemplarily, the electroplating tank 110 can be open or closed, and can be selected according to actual needs, but there are situations in the auxiliary device 120 that require the electroplating tank 110 (such as requiring the electroplating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com