Trivalent chromium plating solution and method for chromium-plating using same

A technology of trivalent chromium and plating solution, which is applied in the field of trivalent chromium plating solution, can solve the problems of slow precipitation of coating and achieve the effect of fast precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The preparation method of the plating solution of the present invention is not particularly limited, for example, by adding and mixing a trivalent chromium compound, a complexing agent, a conductive salt, and a pH buffering agent in water at 40 to 50° C., adding and mixing a sulfur-containing organic compound after dissolving, Finally, it is prepared by adjusting the pH with sulfuric acid, ammonia water, etc.

[0033] The plating solution of the present invention can be used to plate the object to be plated with the plating solution of the present invention in the same manner as the conventional chromium plating solution to plate chrome on the object to be plated.

[0034] The conditions of electroplating are not particularly limited, for example, when the bath temperature is 30-60°C, the anode is carbon or iridium oxide, and the cathode current density is 2-20A / dm 2 Electroplating can be carried out for 1 to 15 minutes under certain conditions.

[0035] Examples of th...

Embodiment 1

[0047] chrome:

[0048] The components described in Table 1 were dissolved in water to prepare a trivalent chromium plating solution. For this trivalent chromium plating solution, a Hull cell test was performed using a nickel-plated brass plate. The conditions of the Hull cell test were a current of 4 A and a plating time of 3 minutes. After plating, follow the figure 1 The distance from the left end of the brass plate to which the plated film was deposited was measured using the method described above, and this was taken as the spreading ability. In addition, the film thickness of the portion corresponding to the current density 8ASD of the brass plate was measured with fluorescent X-rays. In addition, the appearance after plating was evaluated by L value, a value, and b value using a color difference meter (made by Konica Minolta Corporation). These results are also shown in Table 1.

[0049] 【Table 1】

[0050] Bath composition Composition 1 Composition 2...

Embodiment 2

[0058] chrome:

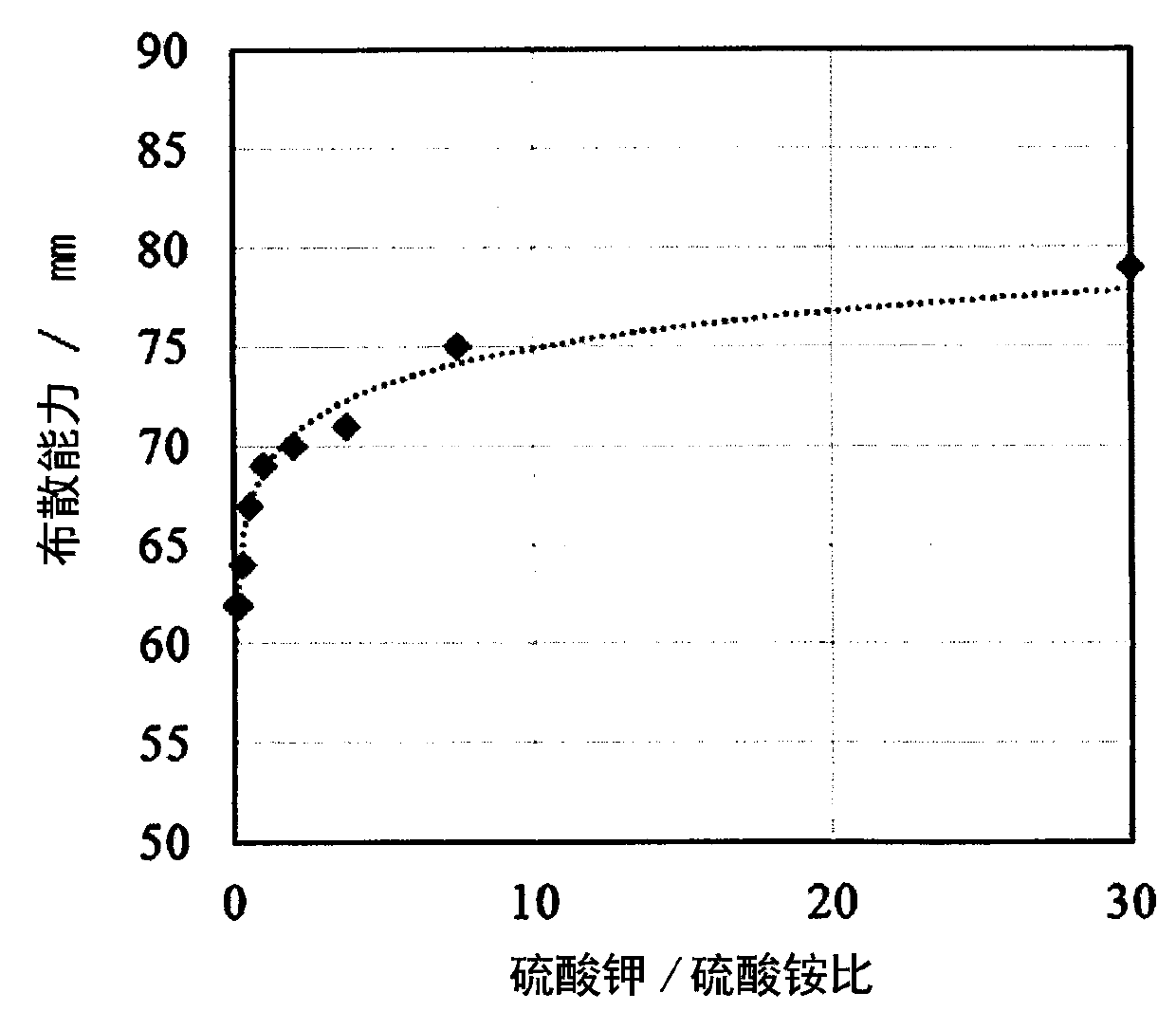

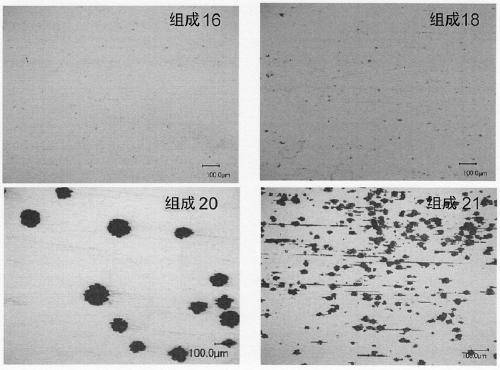

[0059] The components described in Table 2 were dissolved in water to prepare a trivalent chromium plating solution. For this trivalent chromium plating solution, a Hull cell test was performed using a nickel-plated brass plate. The conditions of the Hull cell test were a current of 4 A and a plating time of 3 minutes. After the plating, the distance from the left end of the brass plate to which the plating film was deposited was measured. The results are also shown in Table 2. In addition, the relationship between spreading ability and potassium sulfate / ammonium sulfate is shown in figure 2 .

[0060] 【Table 2】

[0061]

[0062] In the case of plating with the above-mentioned trivalent chromium plating solution, it can be seen that the appearance and film thickness are basically the same in all compositions, but in terms of spreading ability, the larger the potassium sulfate / ammonium sulfate is, the better the spreading ability is. 1.0~ The dispersi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com