Porous carbon composite titanium dioxide-oxyhalide photocatalyst and preparation method thereof

A technology of oxyhalide and titanium dioxide, which is applied in the field of porous carbon composite titanium dioxide-oxyhalide photocatalyst and its preparation, can solve the problems of low conversion efficiency, low reuse rate, short service life, etc., achieve enhanced adsorption capacity, overcome The effect of weak adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A kind of porous carbon composite titania-oxyhalide photocatalyst, its preparation method comprises the steps:

[0036] 1) Weigh a certain mass of titanyl sulfate and ammonia water, mix and stir, and dry after filtering;

[0037] 2) Calcining the product of step 1) at a high temperature at 100°C;

[0038] 3) drop the potassium chloride solution containing bismuth nitrate into the product of step 2), and stir for 1; the temperature is controlled at 30° C.;

[0039] 4) The product of step 3) is separated and dried, put into a container, vacuumized, sealed, and placed at 500°C for 2 to 4 hours;

[0040] 5) Put the product of step 4) into hydrochloric acid solution, soak for 6h; separate, wash with deionized water, and dry;

[0041]6) Put the product of step 5) into the alcohol solution of the porous carbon material precursor, and grow the porous carbon intermediate carbon material in situ at 250°C;

[0042] 7) Place the product of step 6) at 300°C for 15 hours;

[0043...

Embodiment 2

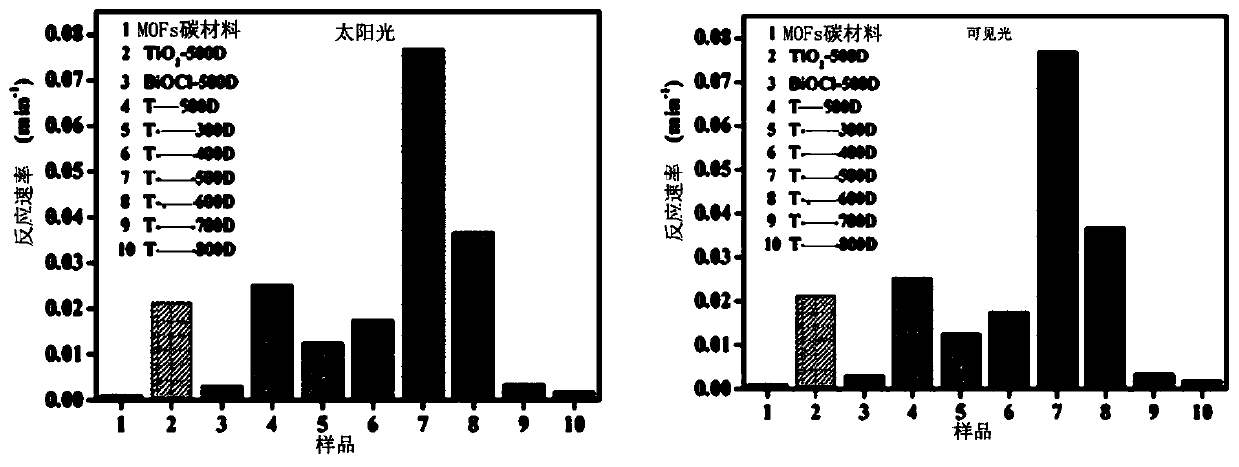

[0047] Example 2: Step 6) of the method for preparing a porous carbon composite titanium dioxide-oxyhalide catalyst described in Example 1) The product calcination temperature is adjusted to 300°C, 400°C, 500°C, 600°C, 700°C, 800°C, and the rest are completely consistent with Example 1.

[0048] The test results are shown in the table below.

[0049]

Embodiment 3

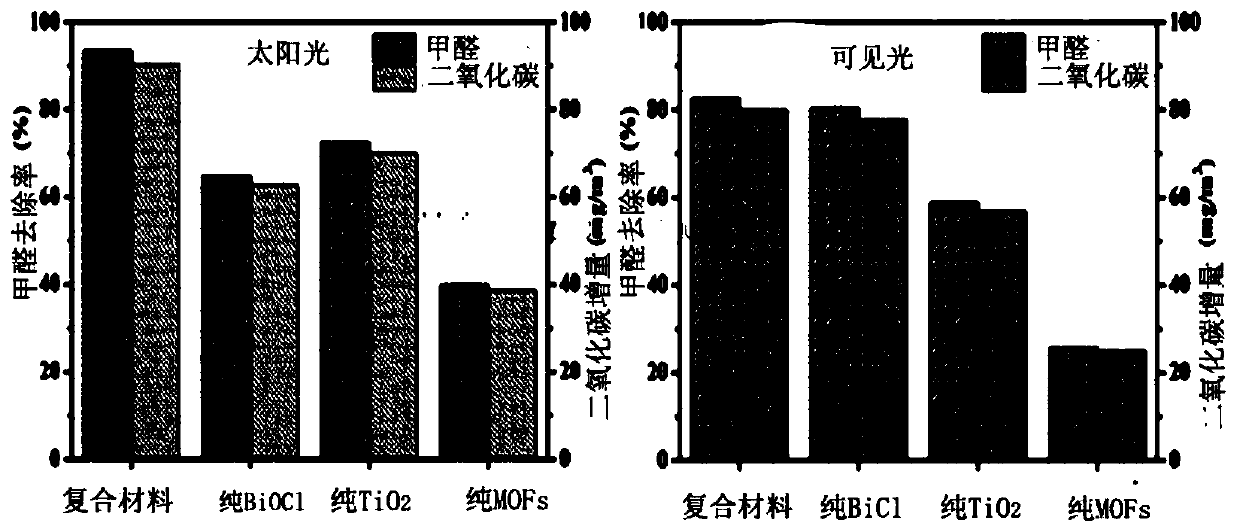

[0050] Embodiment 3: the catalyst type in a kind of porous carbon composite titania-oxyhalide catalyst described in embodiment 1 is adjusted, and regulating catalyst is, pure BiOCl catalyst, pure TiO Catalyst, pure MOF, porous carbon composite titania- Oxyhalide catalyst, all the other parts are completely consistent with embodiment 1

[0051]

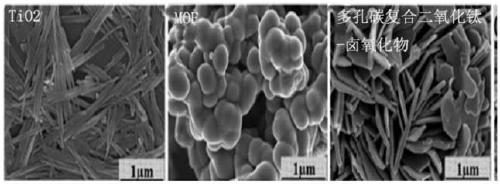

[0052] figure 1 for pure TiO 2 , pure MOFs carbon material, porous carbon composite titanium dioxide-oxyhalide composite material scanning electron microscope, it can be seen that the modified composite material changes significantly, the surface holes increase, and there is an obvious uneven rough structure, indicating that the modification The adsorption capacity of the composite material is enhanced.

[0053] figure 2 for pure TiO 2 , pure MOFs carbon material, porous carbon composite titanium dioxide-oxyhalide composite material parameter diagram, it can be seen that the overall performance of the porous carbon composite ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com