A test device for online detection of polishing pad contact characteristics and its application method

A test device, polishing pad technology, applied in the direction of grinding device, grinding/polishing equipment, grinding machine parts, etc. Accurate and reliable test results, simple additional structure and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

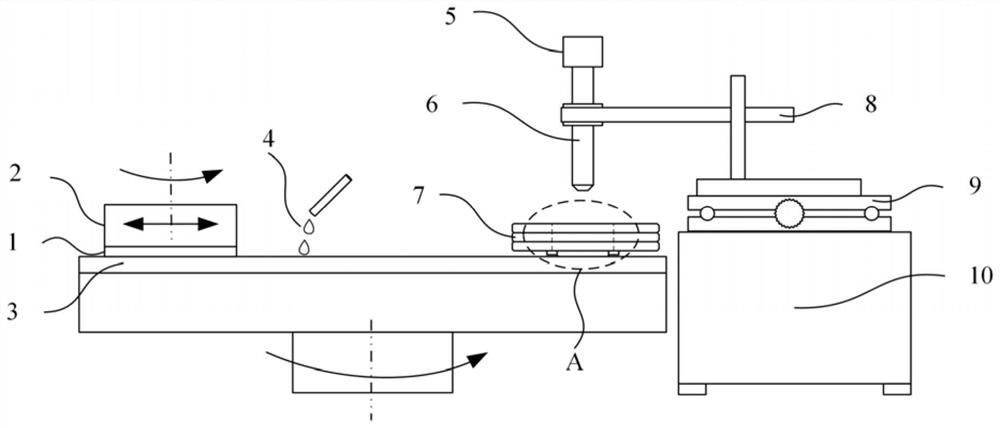

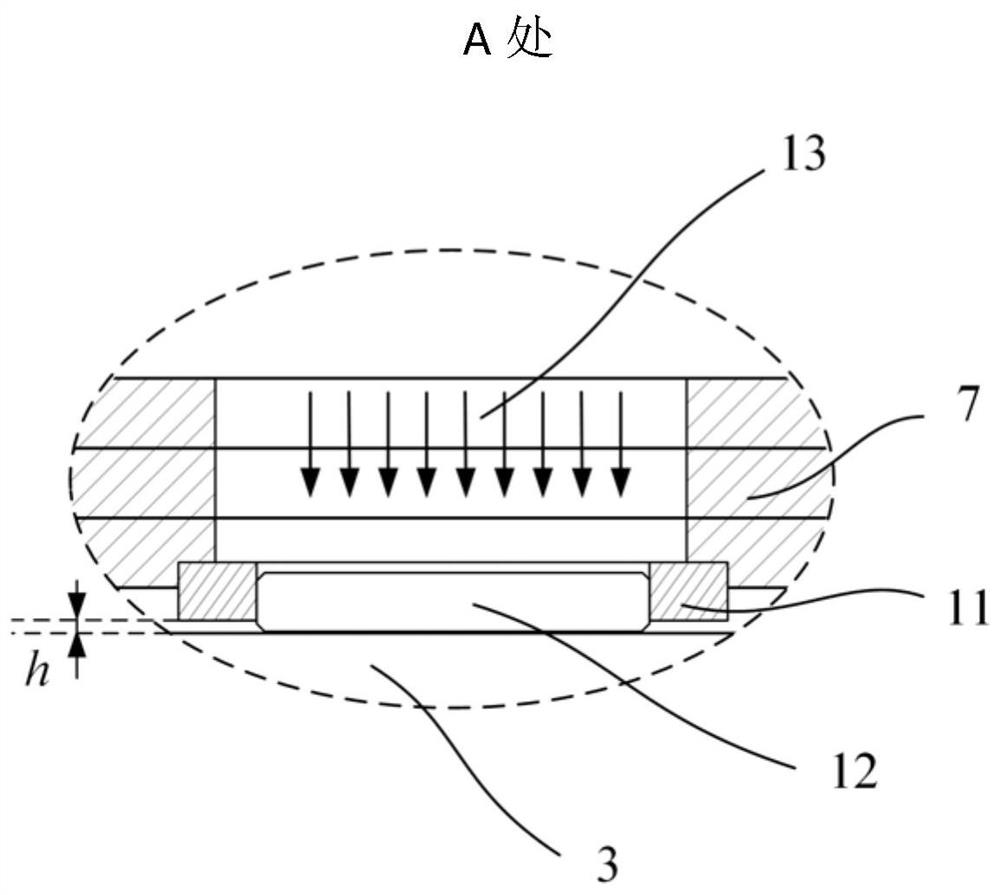

[0047] The present invention will be further described below in conjunction with the accompanying drawings. like Figure 1-2 As shown, a test device for on-line detection of the contact characteristics of the polishing pad includes a base 10, a monocular microscope 6, a CCD camera 5, an XY two-way movable table 9, a sapphire observation window 12, a fixed ring 11, and a counterweight 7 , motion control systems and computers;

[0048] The monocular microscope 6 is installed on the XY two-way moving table 9 through the microscope bracket 8;

[0049] The XY two-way mobile worktable 9 is installed on the base 10;

[0050] The motion control system is connected to the computer through a data line; the motion control system is used to control the movement of the XY two-way mobile worktable 9, realize the function of inching or XY linkage, and complete the specified action through the preset program;

[0051] Described CCD camera 5 has automatic focus function, is matched with mon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com