A high-stiffness, low-viscosity tire compound and its preparation method, and a semi-steel radial tire

A low-viscosity, mixed rubber technology, applied in special tires, tire parts, transportation and packaging, etc., can solve the problems of mixed rubber tear strength and elongation at break, etc., to achieve easy processing and improve processing Sexuality, viscosity-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

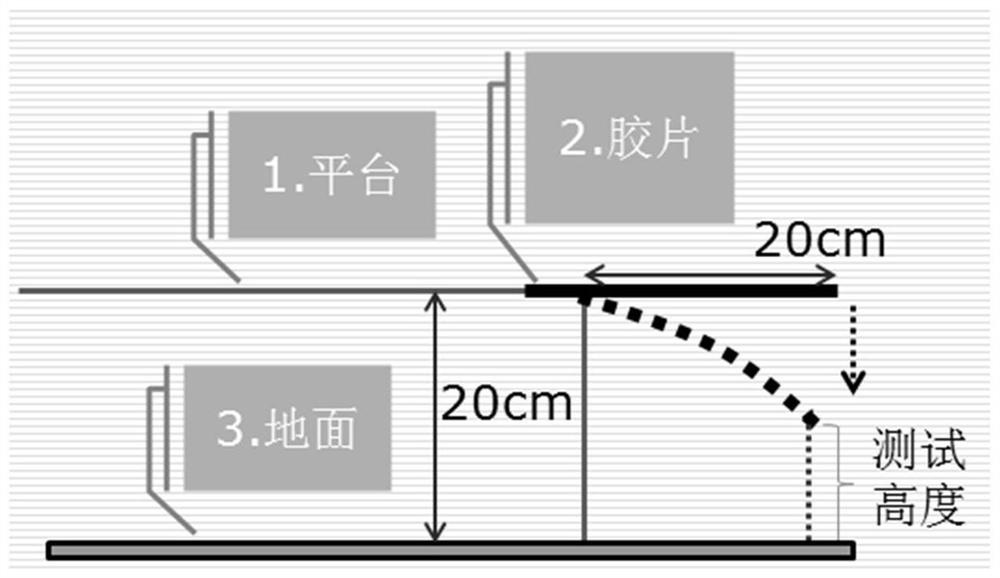

Image

Examples

Embodiment 1 to 8

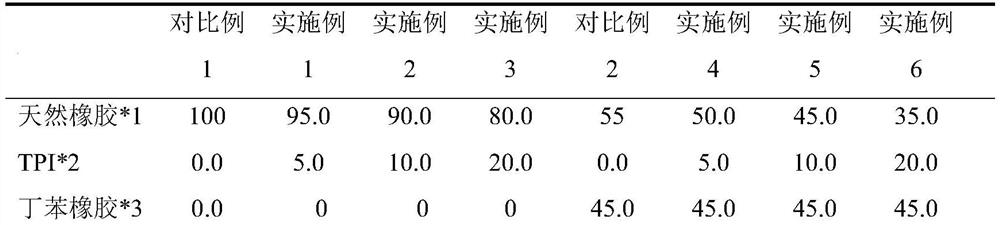

[0029] Examples 1 to 8 are as shown in Table 1 (parts by weight).

[0030] Table 1

[0031]

[0032]

[0033] Table 1 Footnotes

[0034] *1: Vietnam 10# natural rubber mixture;

[0035] *2: Synthesis of 1,4-trans polyisoprene rubber, Wuhan Yuancheng Gongchuang Technology Co., Ltd.;

[0036] *3: SBR1500, product of PetroChina Lanzhou Petrochemical Company;

[0037] *4: N326 carbon black, product of Cabot (China) Investment Co., Ltd.;

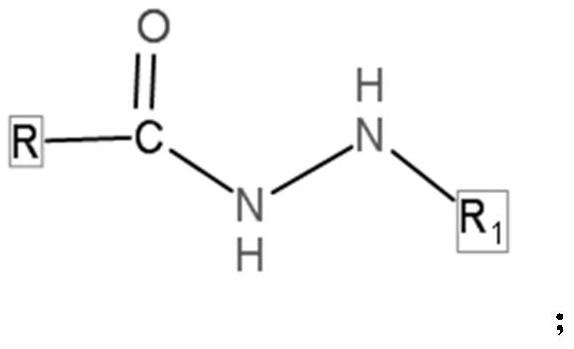

[0038] *5: Hydrazide Substance Modifier DC-02, Otsuka Material Technology Co., Ltd.;

[0039] *6: Zinc oxide (indirect method), product of Shijiazhuang Zhiyi Zinc Industry Co., Ltd.;

[0040] *7: Stearic acid 1808, Baili Co., Ltd.;

[0041] *8: Anti-aging agent 4020, Sennics Technology Co., Ltd.;

[0042] *9: Resin SL3020, Huaqi Chemical Co., Ltd.;

[0043] *10: Plasticizer A, Wuhan Jinghe Chemical Co., Ltd.;

[0044] *11: OKERIN 1987, Bai Rui Mei Special Chemicals Co., Ltd.;

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com