Face mask non-woven fabric with stereoscopic structure, and manufacture method therefor

A technology of three-dimensional structure and production method, which is applied in non-woven fabrics, textiles and paper making, etc., can solve the problems of consumers' troubles in facial masks, unable to maintain the three-dimensional structure for a long time, and achieve increased rigidity and strength, excellent shaping ability, The effect of improving product toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

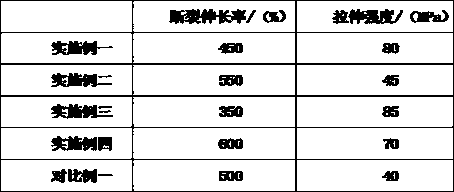

Examples

Embodiment 1

[0023] A non-woven facial mask with a three-dimensional structure is made of the following raw materials in parts by weight: 70wt% polypropylene, 5.0wt% POE elastomer, 5.0wt% calcium carbonate, 0.2wt% nucleating agent, 0.6wt% dispersant, 0.6wt% antioxidant, 0.3wt% hydrophilic auxiliary agent, calcium carbonate is nano-scale calcium carbonate, its particle diameter is 1-10 microns, nucleating agent is nontoxic substituted aryl phosphate salt nucleating agent and others Mixture of organic co-nucleating agents.

[0024] The polypropylene is H1500 transparent high temperature resistant injection grade polypropylene model, and the POE elastomer is 7020FL melt-blown cloth grade POE model.

[0025] The dispersant is a blend of 50% propylene glycol block polyester, 30% optical brightener and 20% polyoxypropylene polyoxyethylene copolymer, and the hydrophilic additive is 10% 1,3-propylene glycol , 10% glycerol and 80% 12-14 mixed alcohol mixture.

[0026] Antioxidant: 10% tetrakis[β-...

Embodiment 2

[0037] A non-woven facial mask with a three-dimensional structure is made of the following raw materials in parts by weight: 70wt% polypropylene, 5.0wt% POE elastomer, 5.0wt% calcium carbonate, 0.6wt% dispersant, 0.6wt% antioxidant, 0.3 The wt% hydrophilic auxiliary agent, the calcium carbonate is nano-scale calcium carbonate, and its particle diameter is 1-10 microns.

[0038] The polypropylene is H1500 transparent high temperature resistant injection grade polypropylene model, and the POE elastomer is 7020FL melt-blown cloth grade POE model.

[0039] The dispersant is a blend of 50% propylene glycol block polyester, 30% optical brightener and 20% polyoxypropylene polyoxyethylene copolymer, and the hydrophilic additive is 10% 1,3-propylene glycol , 10% glycerol and 80% 12-14 mixed alcohol mixture.

[0040] Antioxidant: 10% tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester, 10% tris[2,4-di-tert-butylphenyl] phosphorous acid ester, 10% N,N'-bis-...

Embodiment 3

[0051] A non-woven facial mask with a three-dimensional structure is made of the following raw materials in parts by weight: 70wt% polypropylene, 5.0wt% calcium carbonate, 0.2wt% nucleating agent, 0.6wt% dispersant, 0.6wt% antioxidant, 0.3 The wt% hydrophilic auxiliary agent, calcium carbonate is nano-scale calcium carbonate, and its particle diameter is 1-10 microns, and the nucleating agent is a mixture of non-toxic substituted aryl phosphate salt nucleating agent and other organic auxiliary nucleating agents.

[0052] Polypropylene is H1500 transparent high temperature resistant injection molding grade polypropylene model.

[0053] The dispersant is a blend of 50% propylene glycol block polyester, 30% optical brightener and 20% polyoxypropylene polyoxyethylene copolymer, and the hydrophilic additive is 10% 1,3-propylene glycol , 10% glycerol and 80% 12-14 mixed alcohol mixture.

[0054] Antioxidant: 10% tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com