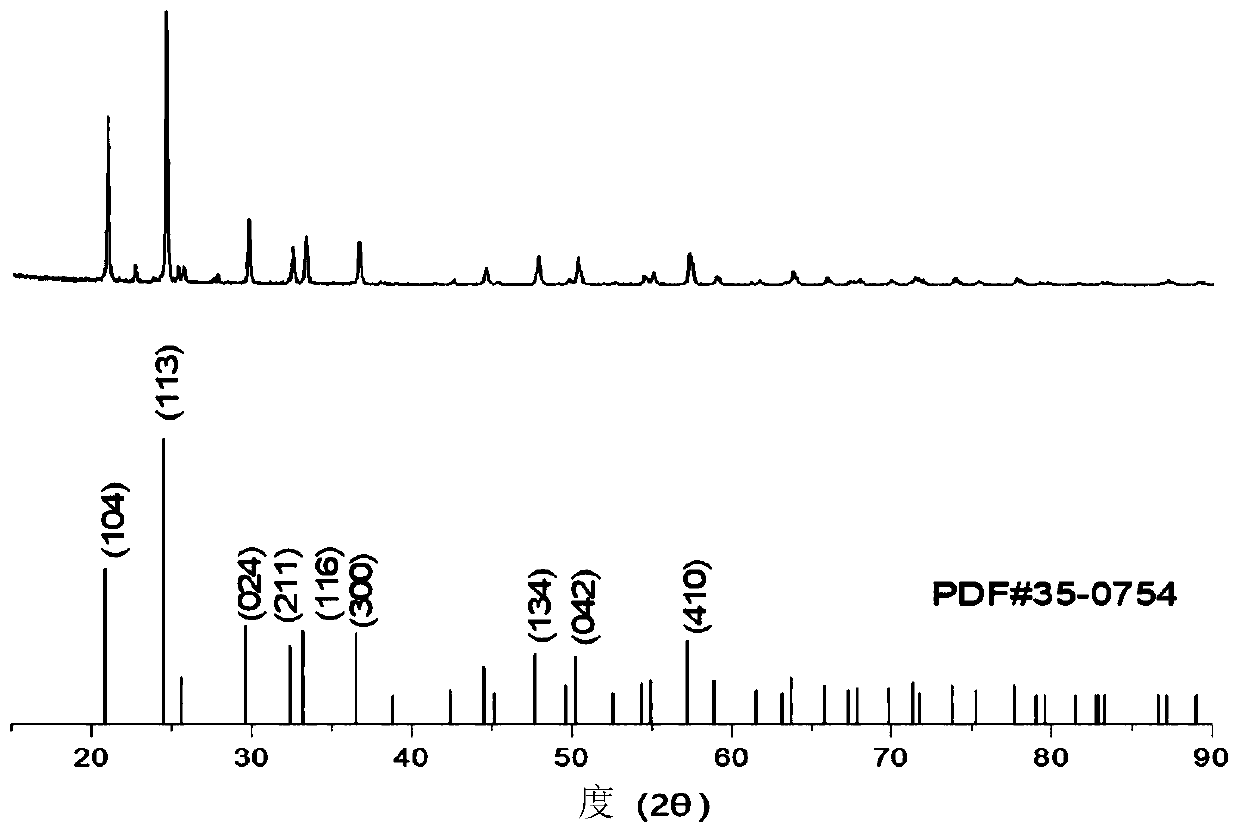

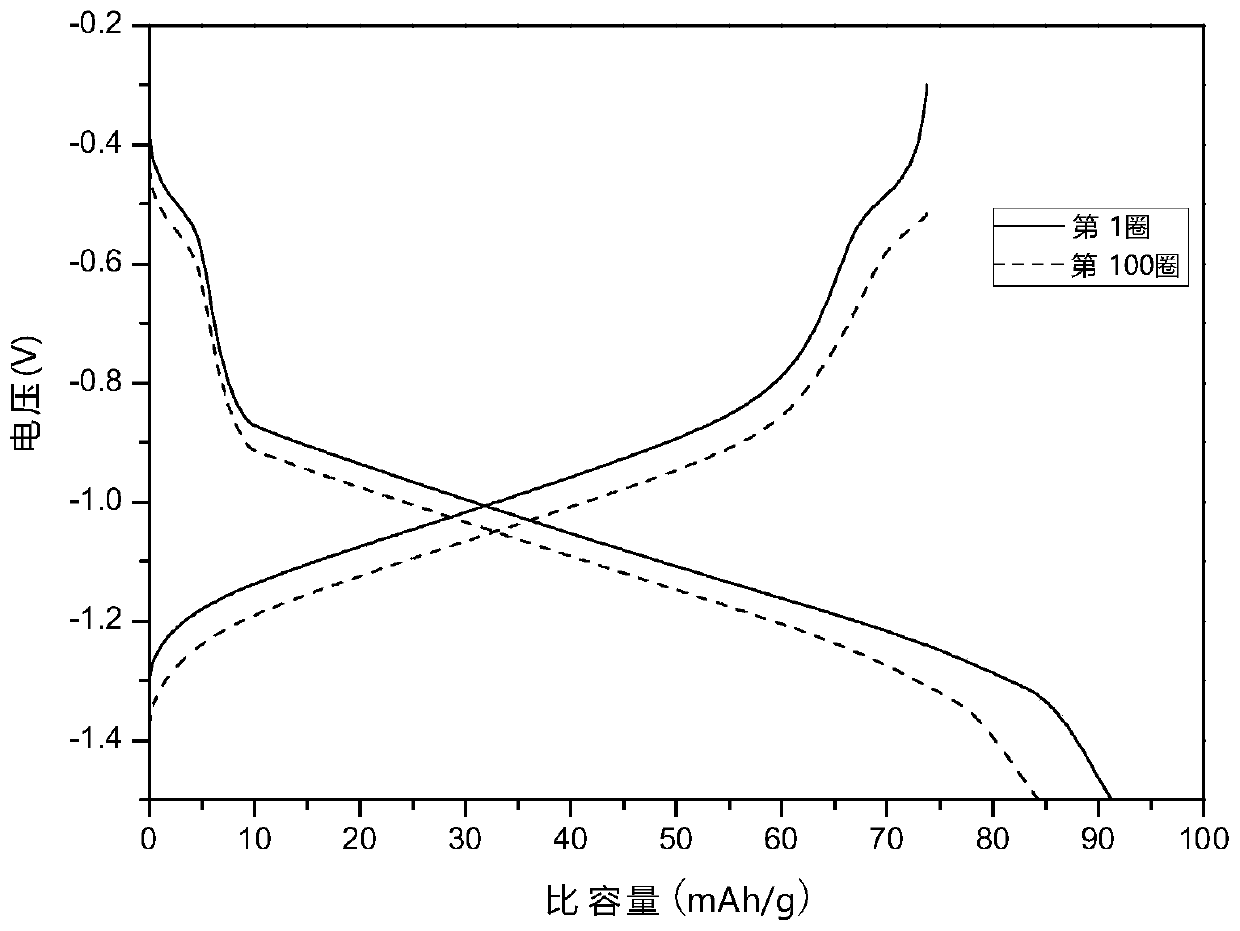

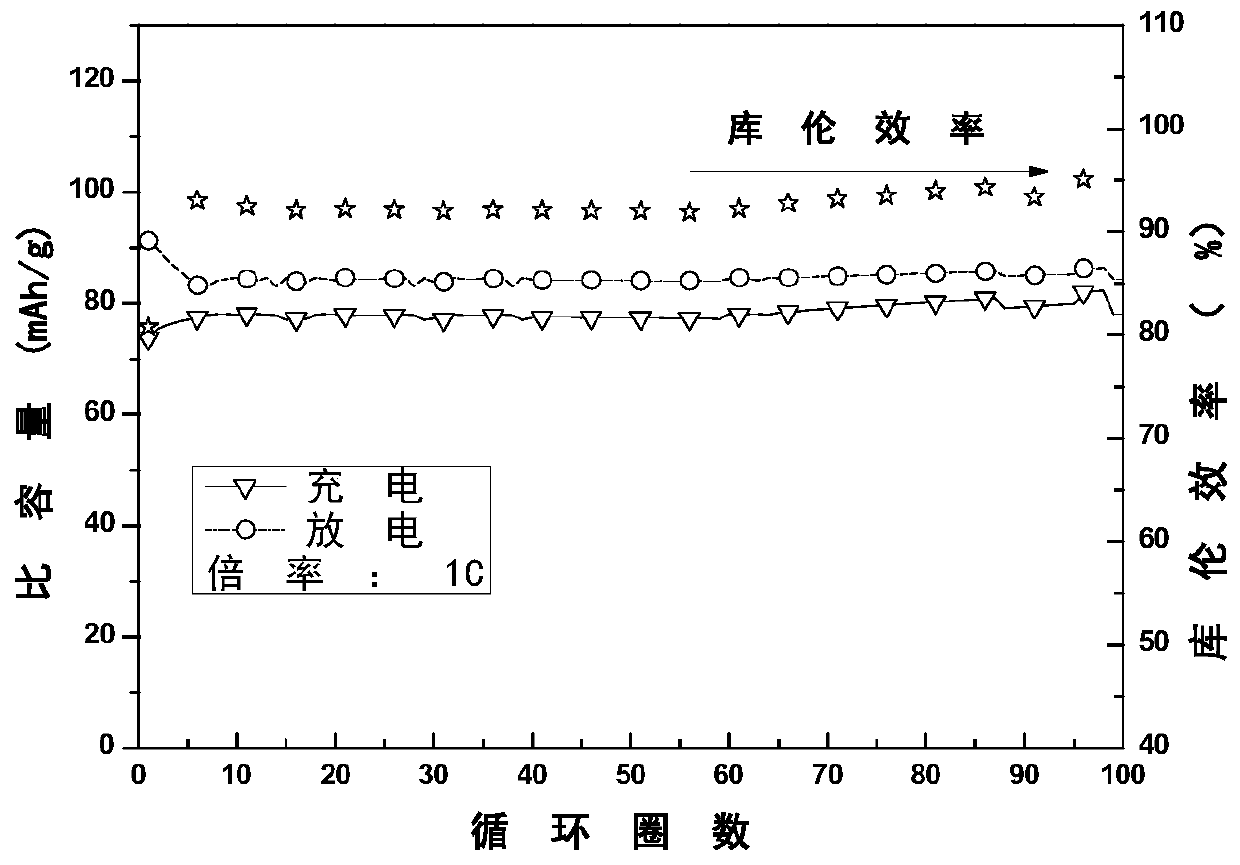

Graphene/lithium titanium phosphate composite material, preparation method thereof and lithium ion battery

A lithium ion battery, lithium titanium phosphate technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of low capacity of lithium titanium phosphate negative electrode, limited energy storage application, etc., and achieve environmental friendliness, cost controllable, good The effect of electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] Step A: According to the volume ratio of 1,3,5-trimethylbenzene and hydrochloric acid solution of 1:20, add 1,3,5-trimethylbenzene into 2.0mol / L hydrochloric acid solution, and continuously stir at 25°C for 30 minutes. Then, the mixture of 1,3,5-trimethylbenzene and hydrochloric acid solution was sonicated for 30 minutes to form an emulsion, wherein the ultrasonic frequency was 40 kHz.

[0060] Step B: At room temperature, according to the volume ratio of distilled water, graphene oxide solution, and emulsion 1:1.5:3, add distilled water and 5.0 mg / mL graphene oxide solution to the above emulsion, and let stand Afterwards, the precipitate was collected by vacuum filtration.

[0061] Step C: The above precipitate is fully mixed with lithium titanium phosphate (the mass ratio of graphene oxide to lithium titanium phosphate is 1:20), and placed in a quartz boat, placed in a tube furnace, under N 2 Under protection, the temperature was raised to 350°C at a heating rate of ...

Embodiment 2

[0063] Step A: According to the volume ratio of toluene to hydrochloric acid solution 1:50, add toluene into 1.0 mol / L hydrochloric acid solution, and stir continuously at 25°C for 30 minutes. Then, the mixture of toluene and hydrochloric acid solution was ultrasonically treated for 40 minutes to form an emulsion, wherein the ultrasonic frequency was 40 kHz.

[0064] Step B: At room temperature, according to the volume ratio of distilled water, graphene oxide solution, and emulsion 1:1:2, add distilled water and 2.0mg / mL graphene oxide solution to the above emulsion, and let stand Afterwards, the precipitate was collected by vacuum filtration.

[0065] Step C: The above precipitate is fully mixed with lithium titanium phosphate (the mass ratio of graphene oxide to lithium titanium phosphate is 1:20), and placed in a quartz boat, placed in a tube furnace, under N 2 Under protection, the temperature was raised to 300°C at a heating rate of 15°C / min, the front section was sinter...

Embodiment 3

[0067] Step A: According to the volume ratio of p-xylene, n-hexadecane and hydrochloric acid solution 0.5:0.5:10, add p-xylene and n-hexadecane to 3.0mol / L hydrochloric acid solution, and continuously stir at 25°C for 30 minutes . Then, the mixture of p-xylene, n-hexadecane and hydrochloric acid solution was ultrasonically treated for 20 minutes to form an emulsion, wherein the ultrasonic frequency was 40 kHz.

[0068] Step B: At room temperature, according to the volume ratio of distilled water, graphene oxide solution, and emulsion 1:2:6, add distilled water and 8.0mg / mL graphene oxide solution to the above emulsion, and let stand Afterwards, the precipitate was collected by vacuum filtration.

[0069] Step C: The above precipitate is fully mixed with lithium titanium phosphate (the mass ratio of graphene oxide to lithium titanium phosphate is 1:20), and placed in a quartz boat, placed in a tube furnace, under N 2 Under protection, the temperature was raised to 500°C at a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com