Production process for dental scarf film made of composite material and production device thereof

A technology of composite materials and production equipment, which is applied in the direction of dentistry, lamination equipment, synthetic resin layered products, etc., can solve the problems of polluted environment, low moisture permeability, easy tearing, etc., and achieve simple production process, high production efficiency, The effect of increasing toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: The formula ratio of the film layer is 1 part of LLDPE, 0.3 part of LDPE, 0.5 part of HDPE, 1 part of calcium carbonate, and 0.3 part of polyisobutylene;

Embodiment 2

[0034] Embodiment 2: the formula ratio of the film layer is 2 parts of LLDPE, 0.6 part of LDPE, 1.3 part of HDPE, 2 parts of calcium carbonate, and 0.6 part of polyisobutylene;

Embodiment 3

[0035] Embodiment three: the formula ratio of the film layer is 3 parts of LLDPE, 1 part of LDPE, 2 parts of HDPE, 3 parts of calcium carbonate, and 1 part of polyisobutylene;

[0036] Working process of the present invention:

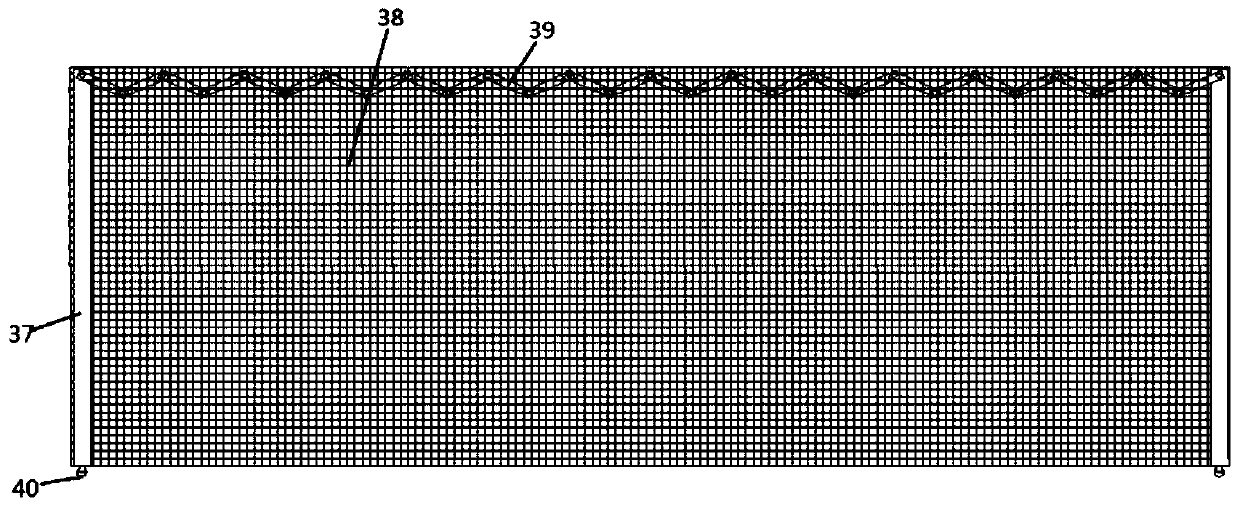

[0037] 1. First, the insect-proof cover 36 is opened, and the telescopic rod 39 is driven to move with the pin as the base point by pushing the telescopic bracket 37, thereby opening the gauze 38 installed on the telescopic bracket 37, and the compound mechanism 4 and the winding mechanism are connected by the gauze 38. 5. Surround it to avoid insects flying to the film during the winding process and sticking to the film, making the film unusable;

[0038] Two, the purification fan 32 and the air cleaner 33 are opened, and the odor generated during film blow molding and the gas polluting the environment are sucked into the air cleaner 33 by the purification fan 32, and discharged after being purified by the air cleaner 33, which is beneficial to enviro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com