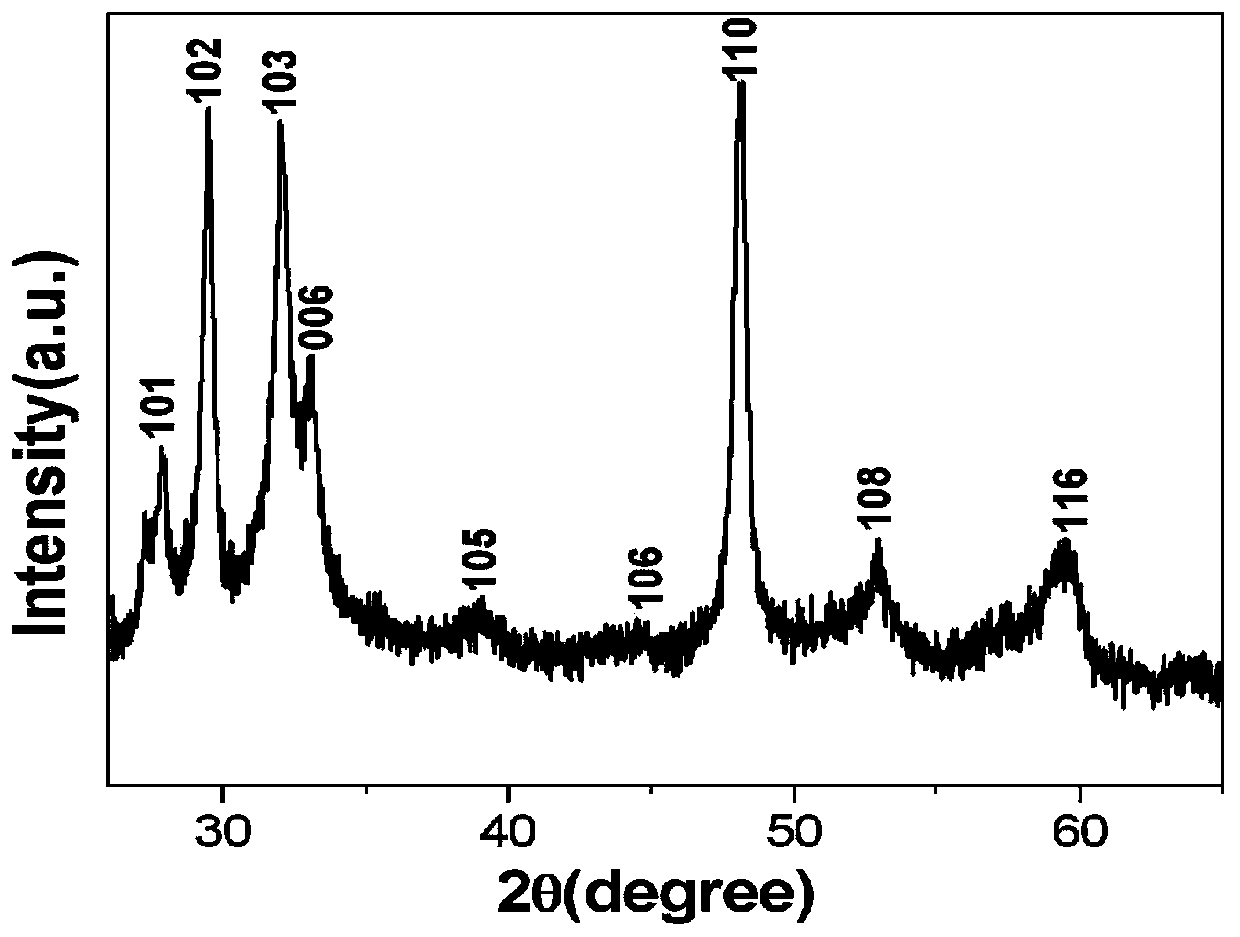

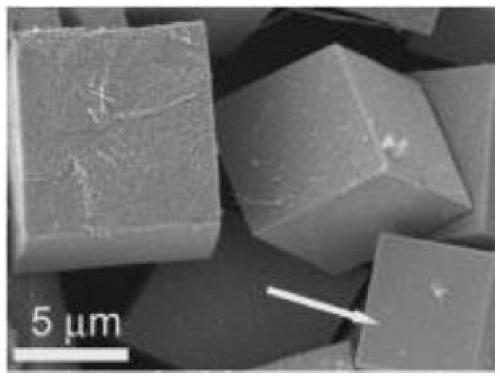

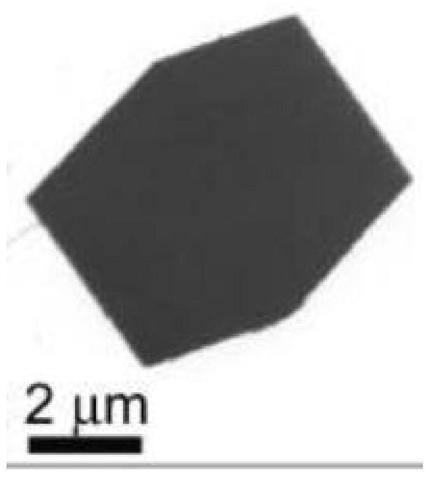

Preparation method of solid cubic blocky copper sulfide

A copper sulfide, cubic technology, applied in the direction of copper sulfide, etc., to achieve the effect of reducing the degree of environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Step 1: Dissolve 1 mmol of copper chloride in a mixed solvent (volume ratio of 1:1) composed of absolute ethanol and distilled water, stir magnetically for 6 minutes, mix well, prepare a copper chloride mixed solution, and set aside;

[0024] Step 2: Take 1 mmol of L-methionine and dissolve it in a mixed solvent composed of absolute ethanol and distilled water, stir it with a magnetic force for 6 minutes, mix well, and prepare a mixed solution of L-methionine for later use;

[0025] Step 3: According to the molar ratio of 1:1, take the mixed solution prepared in step 1 and the mixed solution prepared in step 2 respectively, and place them in a polytetrafluoroethylene-lined solvothermal reactor. After sealing, place the solvothermal reactor React at 180°C for 21 hours in a dry box. Naturally cool to room temperature then, obtain reaction product, standby;

[0026] Step 4: Add absolute ethanol solution to the product obtained in Step 3, mix completely, then perform centr...

Embodiment 2

[0028] Step 1: Dissolve 1 mmol of copper chloride in a mixed solvent (volume ratio of 1:2) composed of absolute ethanol and distilled water, stir magnetically for 8 minutes, and mix well to prepare a mixed solution of copper chloride for future use;

[0029] Step 2: Take 2 mmol of L-methionine and dissolve it in a mixed solvent composed of absolute ethanol and distilled water, stir it with a magnetic force for 8 minutes, mix well, and prepare a mixed solution of L-methionine for later use;

[0030] Step 3: According to the molar ratio of 1:2, take the mixed solution prepared in step 1 and the mixed solution prepared in step 2 respectively, and place them in a polytetrafluoroethylene-lined solvothermal reactor. After sealing, place the solvothermal reactor React at 190°C for 22 hours in a dry box. Naturally cool to room temperature then, obtain reaction product, standby;

[0031] Step 4: Add absolute ethanol solution to the product obtained in Step 3, mix completely, then perf...

Embodiment 3

[0033] Step 1: Dissolve 1 mmol of copper chloride in a mixed solvent (volume ratio of 1:2.5) composed of absolute ethanol and distilled water, stir magnetically for 10 minutes, mix well, and prepare a mixed solution of copper chloride for future use;

[0034] Step 2: Take 2.5 mmol of L-methionine and dissolve it in a mixed solvent composed of absolute ethanol and distilled water, stir it with a magnetic force for 10 minutes, mix well, prepare a mixed solution of L-methionine, and set aside;

[0035] Step 3: According to the molar ratio of 1:2.5, take the mixed solution prepared in step 1 and the mixed solution prepared in step 2 respectively, and place them in a polytetrafluoroethylene-lined solvothermal reactor. After sealing, place the solvothermal reactor React at 200°C for 23 hours in a dry box. Naturally cool to room temperature then, obtain reaction product, standby;

[0036] Step 4: Add absolute ethanol solution to the product obtained in Step 3, mix completely, then p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com