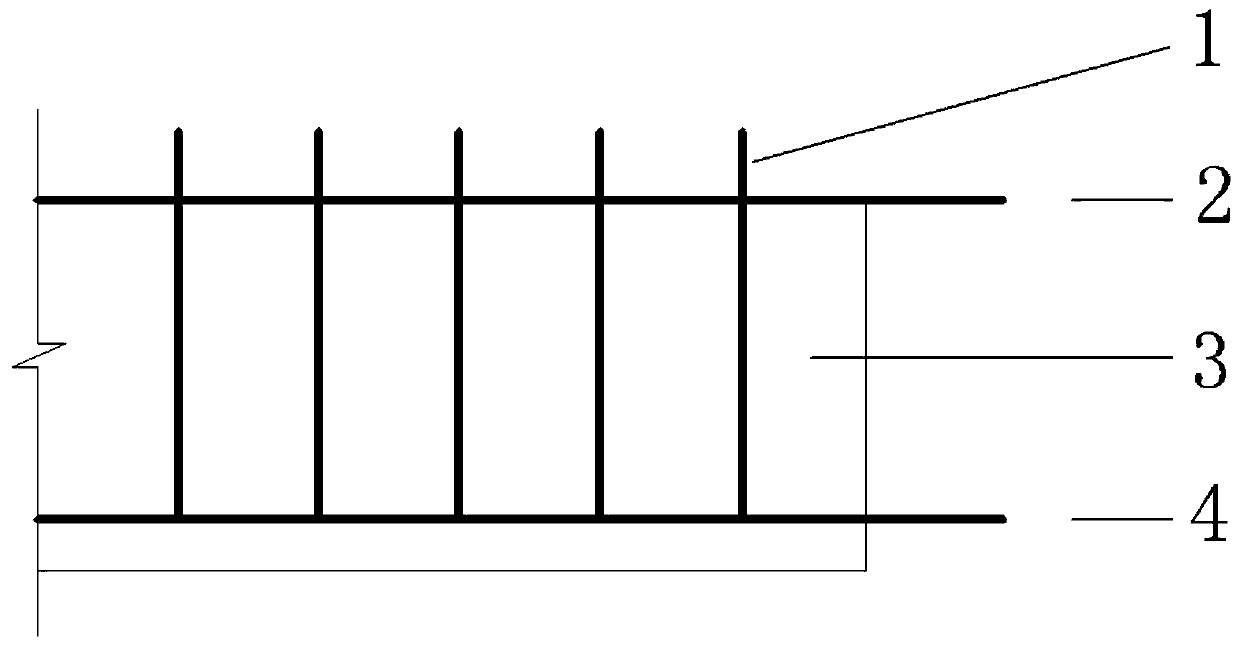

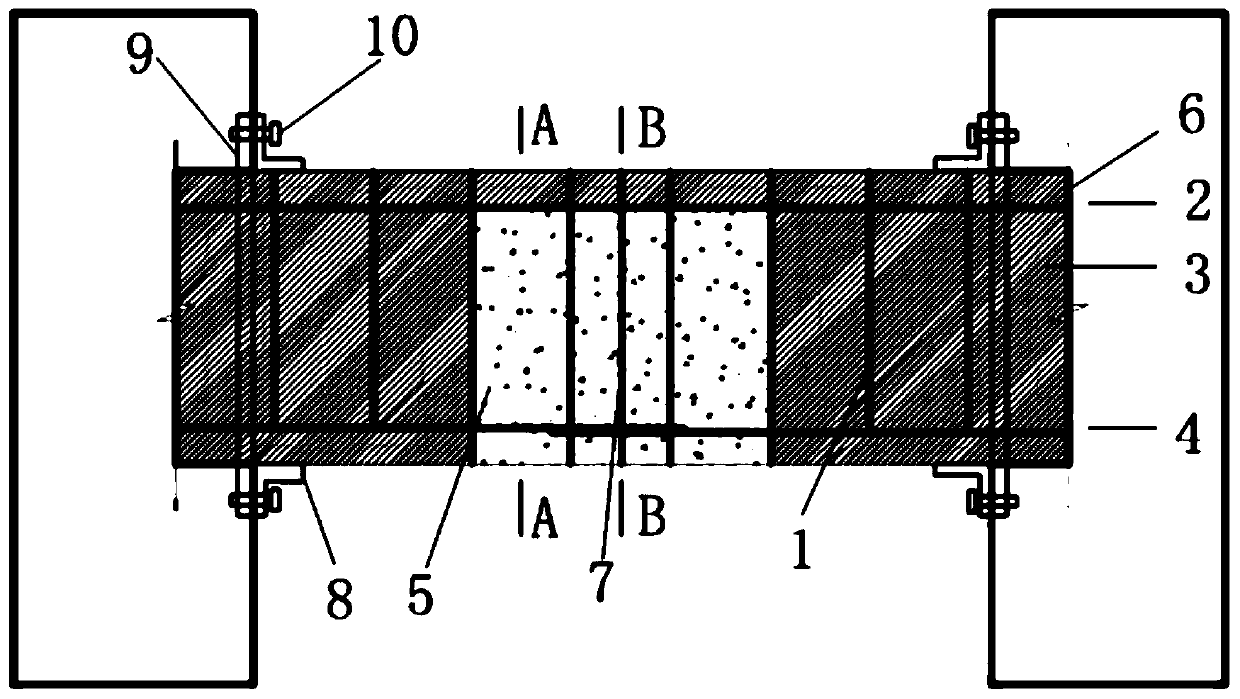

Self-repairing concrete and recycled aggregate assembled reinforced concrete coupling beam, and preparation methods thereof

A technology of reinforced concrete and recycled aggregates, applied in joists, girders, trusses, etc., can solve the problems of low strength, poor seismic performance, weak repair ability, etc., and achieve strong seismic performance, easy operation, and recycling of construction waste. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

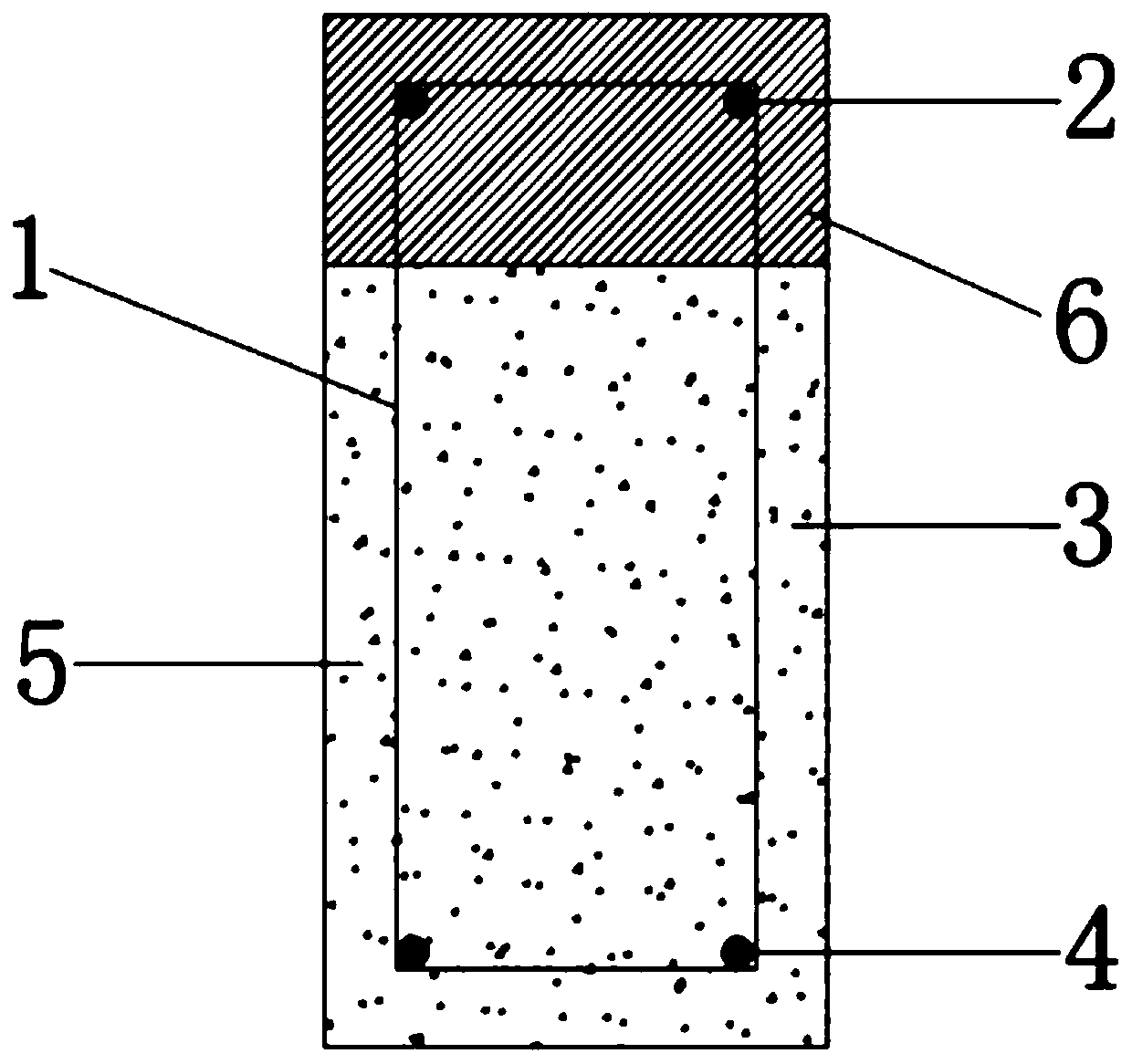

[0049] This embodiment provides a kind of self-repairing concrete, and the self-repairing concrete is microbial self-repairing concrete, and the microbial self-repairing concrete is calculated by volume percentage, and is composed of concrete ingredients, recycled aggregate and Bacillus pasteurian bacteria liquid; wherein the bacteria liquid volume ratio is water Density value conversion mass ratio; other component volume ratio conversion mass ratio weighing;

[0050] The volume dosage of the regenerated aggregate is 25% of the total volume of the microbial self-repairing concrete, based on the cement in the concrete, the volume dosage of the Bacillus pasteurian bacteria liquid is 35% of the total volume of the microbial self-repairing concrete , the water-cement ratio is 0.48, the water-to-bacteria liquid ratio is 1.8; recycled aggregate: dry powder of Bacillus pasteurianus = 1: (0.007-0.013).

[0051] The concrete batching is composed of sand, stone, cement and water by volu...

Embodiment 2

[0069] With embodiment 1, difference is that the Bacillus pasteurian bacterial liquid concentration of the present embodiment is divided into 2~2.4×10 8 cfu / ml, 2~2.4×10 9 cfu / ml, 2~2.4×10 10 cfu / ml; the volume dosage of the Bacillus pasteurian bacteria solution is 35% of the total volume of the microbial self-repairing concrete; the specimens prepared under the three concentrations are respectively marked as BRC1, BRC2, and BRC3.

[0070] According to the mass ratio, the concrete is mixed according to sand: stone: cement: water = (3.08 ~ 3.32): (1.53 ~ 1.79): (1.02 ~ 1.27): (0.54 ~ 0.66), the cement is PO 42.5 grade, and the density is 3150kg / m 3 ; The fineness modulus of sand is 2.6, and the average particle size is 0.23-0.50mm; the apparent density of stone is 2670-2800kg / m 3 , the water content is 3.35-3.48%, and the water absorption rate is 1.77-1.91%. In the process of mixing, add (according to the volume percentage of self-repairing concrete) 25% recycled aggregate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com