Silicon nitride combined castable for blast furnace skimmer and blast furnace skimmer

A slag skimmer and silicon nitride technology, applied in the field of refractory materials, can solve the problem of incomplete description of technical design structure scheme, formula combination advantages and raw material characteristics, unable to achieve creative and beneficial use effects, unfavorable to environmental protection and volatility Extremely strong and other problems, to achieve the effect of reducing comprehensive operating costs, significant economic and social benefits, and convenient and rapid floating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

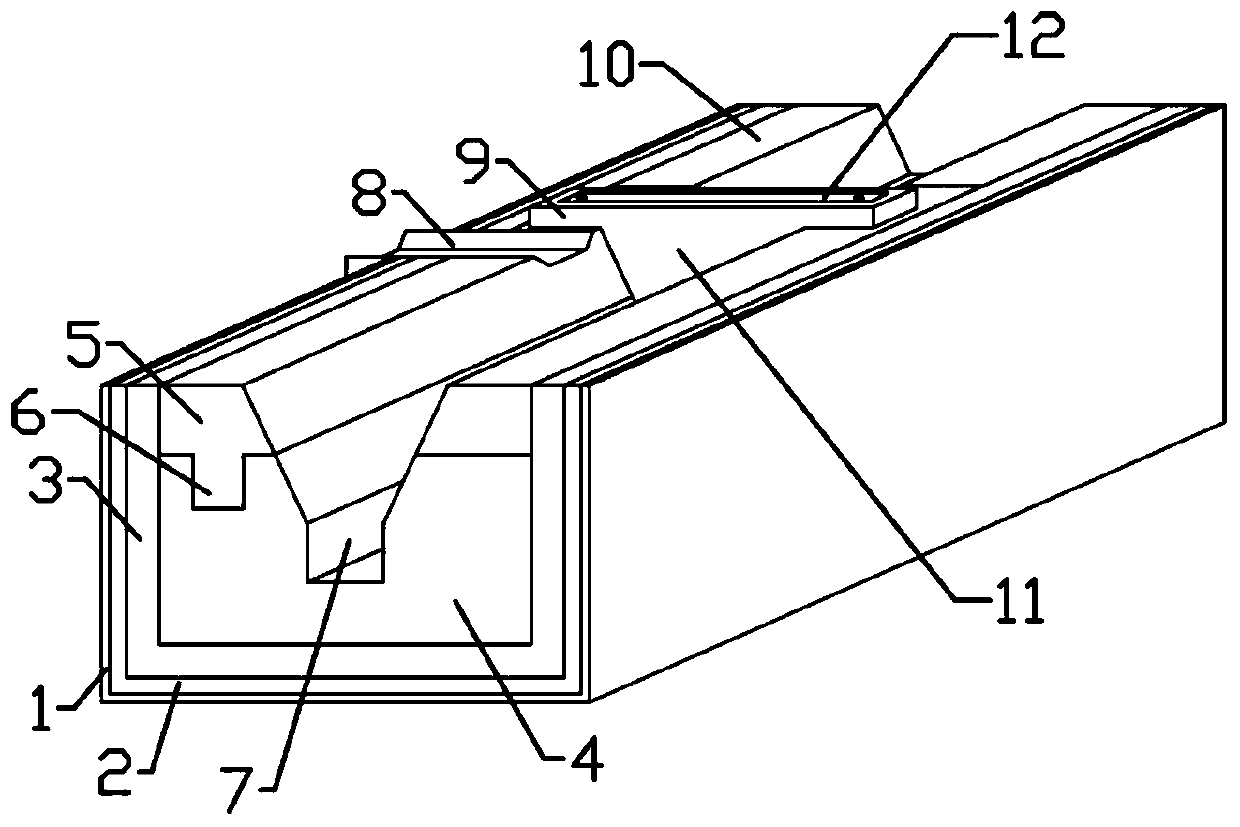

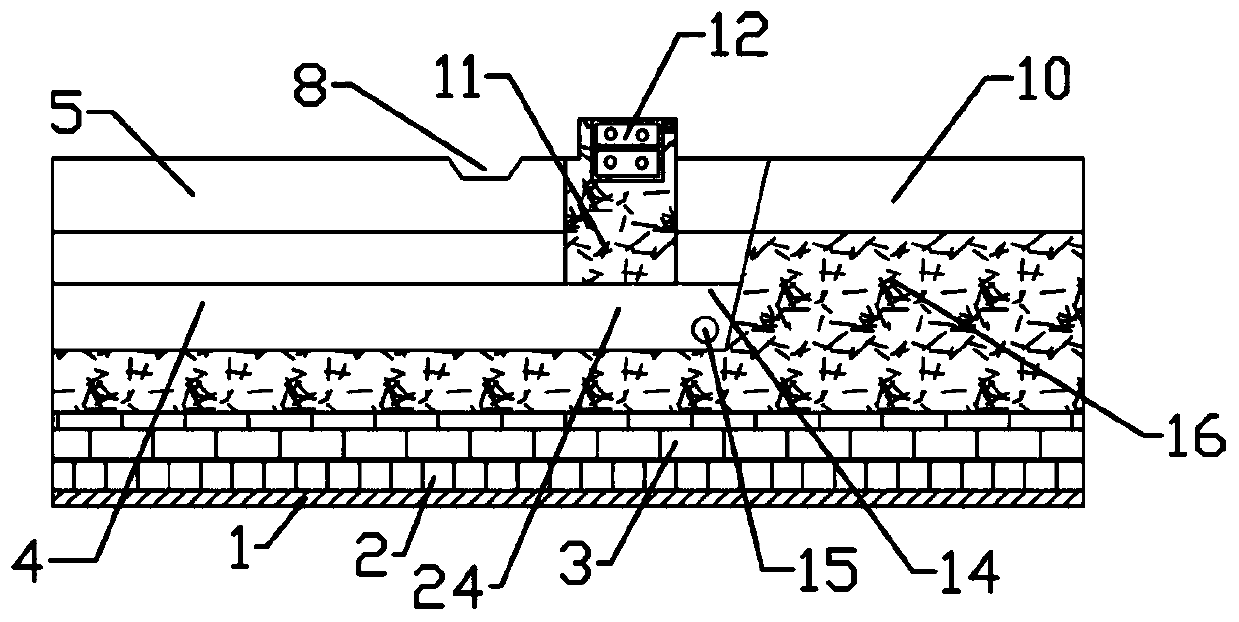

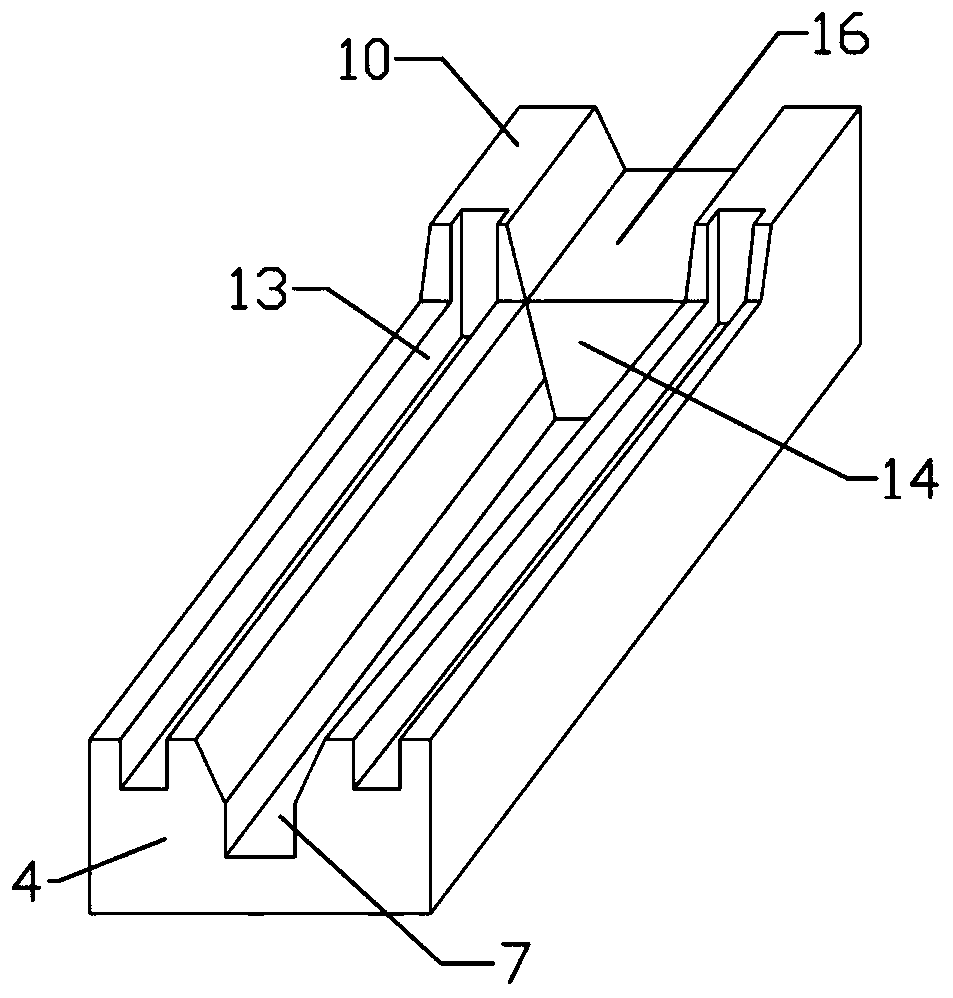

[0059] Such as Figure 1-7 As shown, a blast furnace slag skimmer includes a steel shell 1, a lightweight heat-insulating brick layer 2 is built inside the steel shell, a high-alumina silicon carbide brick layer 3 is built inside the light-weight heat-insulating brick layer, and a high-alumina silicon carbide brick layer The inner side of the layer is installed with a pouring work lining, and the upper end of the pouring work lining is processed with a molten iron groove 7, and the upper end of the molten iron groove is detachably installed with a pouring lintel, forming a molten iron channel 24 between the pouring lintel and the lower end of the molten iron groove, and the pouring work lining The upper end is located at the front side of the pouring lintel and is processed with a slag outlet 8. The pouring work lining includes a pouring bottom support 4, and a pouring wear-resistant block 5 is installed along the molten iron groove on the front side of the pouring bottom suppo...

Embodiment 2

[0064] Such as Figure 1-7 As shown, a blast furnace skimmer is different from other embodiments in that the silicon nitride bonded castable for the blast furnace skimmer is made of the following raw materials, fused dense corundum 35Kg, high-purity spinel 24Kg, black silicon carbide 23Kg, mullite hollow sphere 14Kg, silicon nitride micropowder 9Kg, sillimanite 10Kg, alumina micropowder 7Kg, cordierite 6Kg, aluminate cement 1Kg, ball clay 2Kg, explosion-proof fiber 0.3Kg , Dispersant 0.42Kg, test results see attached table 2.

Embodiment 3

[0066] Such as Figure 1-7 As shown, a blast furnace skimmer is different from other embodiments in that the silicon nitride bonded castable for the blast furnace skimmer is made of the following raw materials, fused dense corundum 45Kg, high-purity spinel 20Kg, black silicon carbide 15Kg, mullite hollow sphere 15Kg, silicon nitride micropowder 5Kg, sillimanite 5Kg, alumina micropowder 5Kg, cordierite 6Kg, aluminate cement 1Kg, ball clay 0.8Kg, anti-explosion fiber 0.3 Kg, dispersant 0.3Kg, test results see attached table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com