A sealing filling material for coke oven protection plate cracks and its manufacturing method

A technology of protective plates and fillers, which is applied in the heating of coke ovens, coke ovens, coke oven parts, etc., can solve the problems of high cost, easy volatilization of solvents at high temperatures, and carbonization, so as to improve the degree of sealing and reduce risk of leakage. Effect of smoke and fugitive emissions, good flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

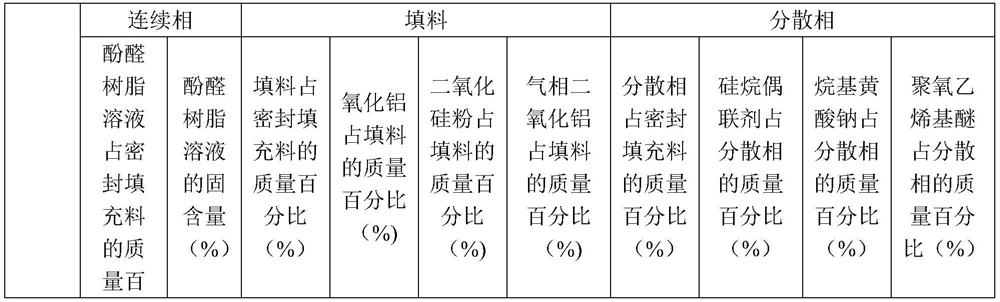

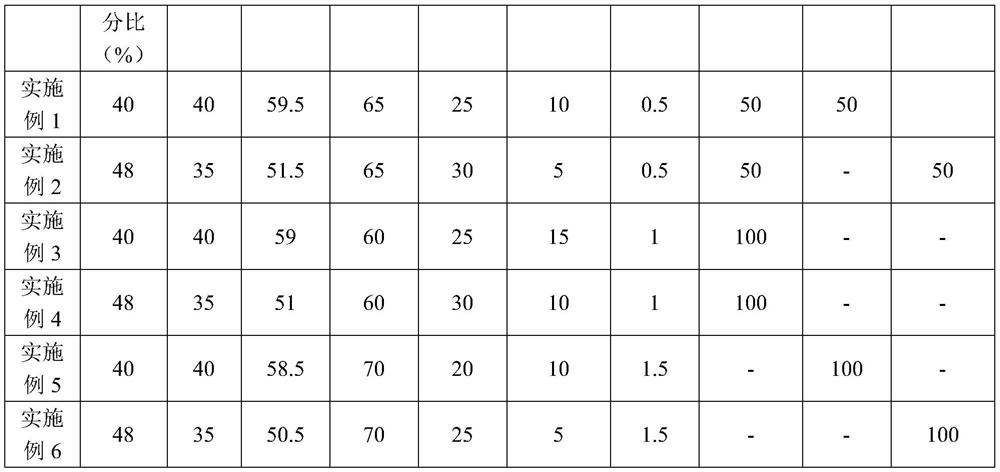

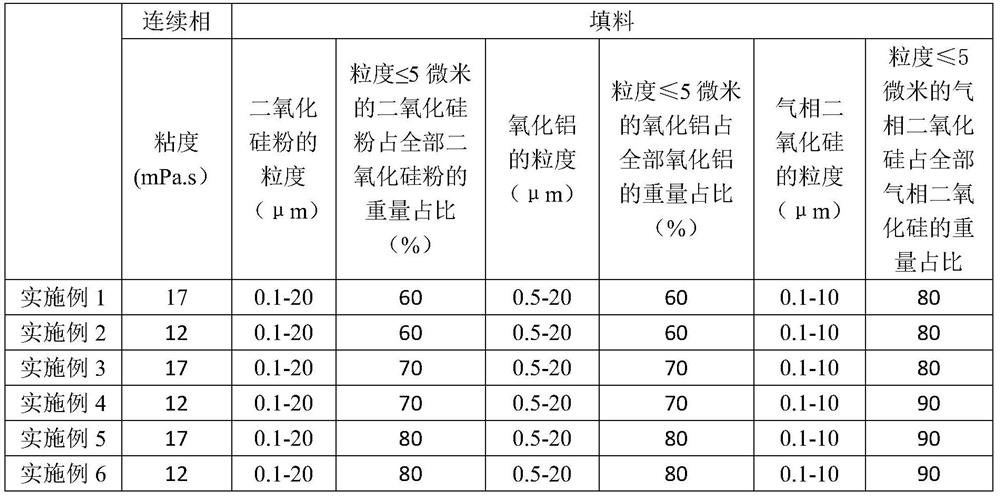

[0066] Embodiment 1-6 is used for the sealing packing material of coke oven protective plate crack and adopts following steps to manufacture:

[0067] Preparation of phenolic resin solution;

[0068] Use at least one of silane coupling agent, sodium alkyl xanthate and polyoxyethylene ether to prepare an aqueous solution, the mass percentage of the above aqueous solution can be 10%, and then add it to the phenolic resin solution according to the formula ratio; in some other In an embodiment of the present invention, the mass percentage of the aqueous solution can be configured as any value within the mass percentage range of 5-15% in addition to 10%.

[0069] Prepare alumina powder, silica powder and fumed silica according to the formula ratio to make filler, mix well and add to phenolic resin solution.

[0070] The mass percentage ratio of each component of the sealing filler of embodiment 1-6 is:

[0071] Phenolic resin solution as continuous phase: 34.7-49.7%;

[0072] Si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com