Low-cost 780MPa-grade cold-rolling dual-phase steel and production method thereof

A production method and low-cost technology, applied in the field of metallurgy, can solve the problems of large temperature fluctuation range, high production cost, high alloy cost, etc., and achieve the effects of high elongation, increased cooling speed, and excellent stamping performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

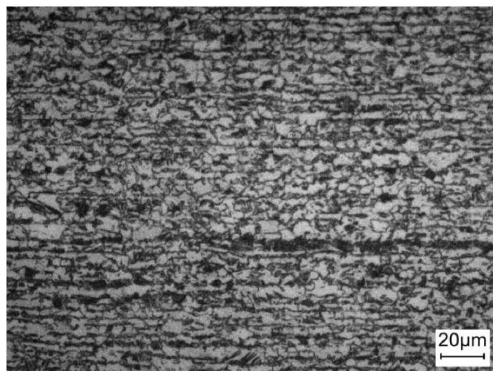

Image

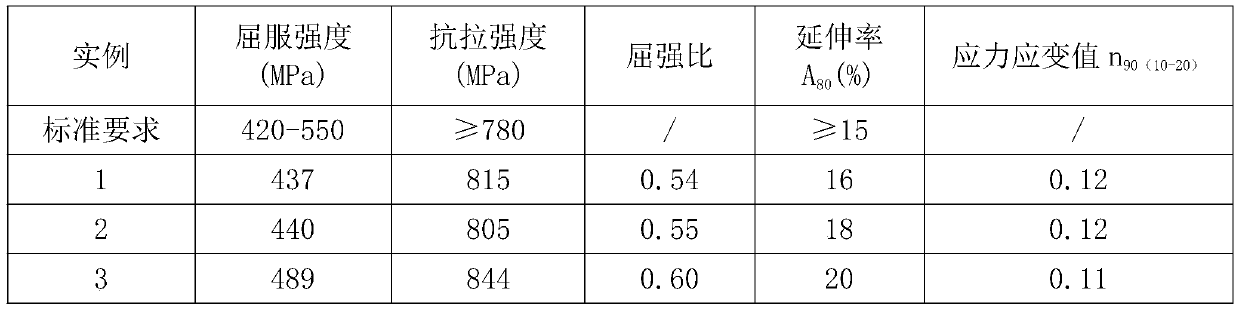

Examples

Embodiment 1

[0039] Adopt KR method to desulfurize molten iron and high-quality steel scrap, LF single refining, adjust the flow of argon gas to make the molten steel in a soft blowing state, feed calcium wire for calcium treatment, and ensure the soft blowing time is more than 8 minutes after feeding the wire to prevent the molten steel from being exposed. The slab is continuously cast with full protection pouring, and the dynamic soft reduction technology is adopted to reduce the center segregation of the continuous casting slab, and the slab is cold loaded into the furnace.

[0040] The center porosity of the slab is grade 0, and the central segregation class C is grade 1.0. It is cold loaded into the furnace, the furnace temperature is 1240°C, the soaking time is 35 minutes, and the furnace time is 200 minutes. The rough rolling is rolled in 6 passes, the phosphorus removal water in the rough rolling is opened in each pass, the pressure of the phosphorus removal water is 22Mpa, the fini...

Embodiment 2

[0042] Adopt KR method to desulfurize molten iron and high-quality steel scrap, LF single refining, adjust the flow of argon gas to make the molten steel in a soft blowing state, feed calcium wire for calcium treatment, and ensure the soft blowing time is more than 8 minutes after feeding the wire to prevent the molten steel from being exposed. The slab is continuously cast with full protection pouring, and the dynamic soft reduction technology is adopted to reduce the center segregation of the continuous casting slab, and the slab is cold loaded into the furnace.

[0043] The center porosity of the slab is 0.5, and the center segregation is C-class 0.5. It is cold loaded into the furnace, the temperature of the furnace is 1230 ℃, the soaking time is 40 minutes, and the time in the furnace is 180 minutes. The rough rolling is rolled in 6 passes, the rough rolling dephosphorization water is opened in each pass, the dephosphorization water pressure is 22Mpa, the finishing rolling...

Embodiment 3

[0045] Adopt KR method to desulfurize molten iron and high-quality steel scrap, LF single refining, adjust the flow of argon gas to make the molten steel in a soft blowing state, feed calcium wire for calcium treatment, and ensure the soft blowing time is more than 8 minutes after feeding the wire to prevent the molten steel from being exposed. The slab is continuously cast with full protection pouring, and the dynamic soft reduction technology is adopted to reduce the center segregation of the continuous casting slab, and the slab is cold loaded into the furnace.

[0046] The center porosity of the slab is 0.5, and the central segregation C class is 1.5. It is cold loaded into the furnace, the temperature of the furnace is 1235 ℃, the soaking time is 35 minutes, and the time in the furnace is 188 minutes. The rough rolling is rolled in 6 passes, the phosphorus removal water in the rough rolling is opened in each pass, the phosphorus removal water pressure is 22Mpa, the finish ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com