Photoetching plate surface damage repairing solution and application thereof

A technology for surface damage and photolithography, which is applied in the field of photolithography surface damage repair solution, can solve the problems of photomask coating thickness thinning, unfavorable use of redox, high cleaning cost, etc., and achieves simple configuration and use , Improve product quality, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

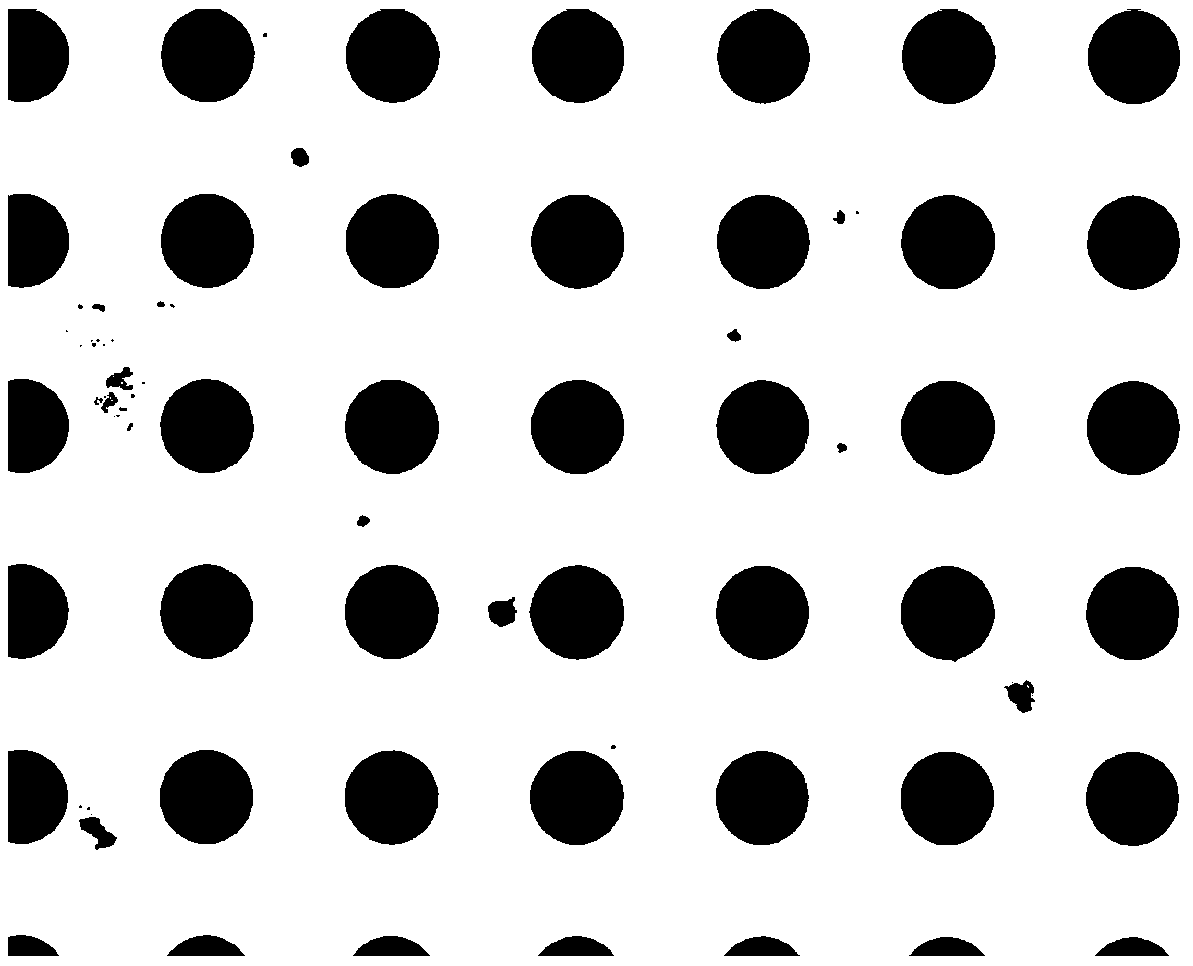

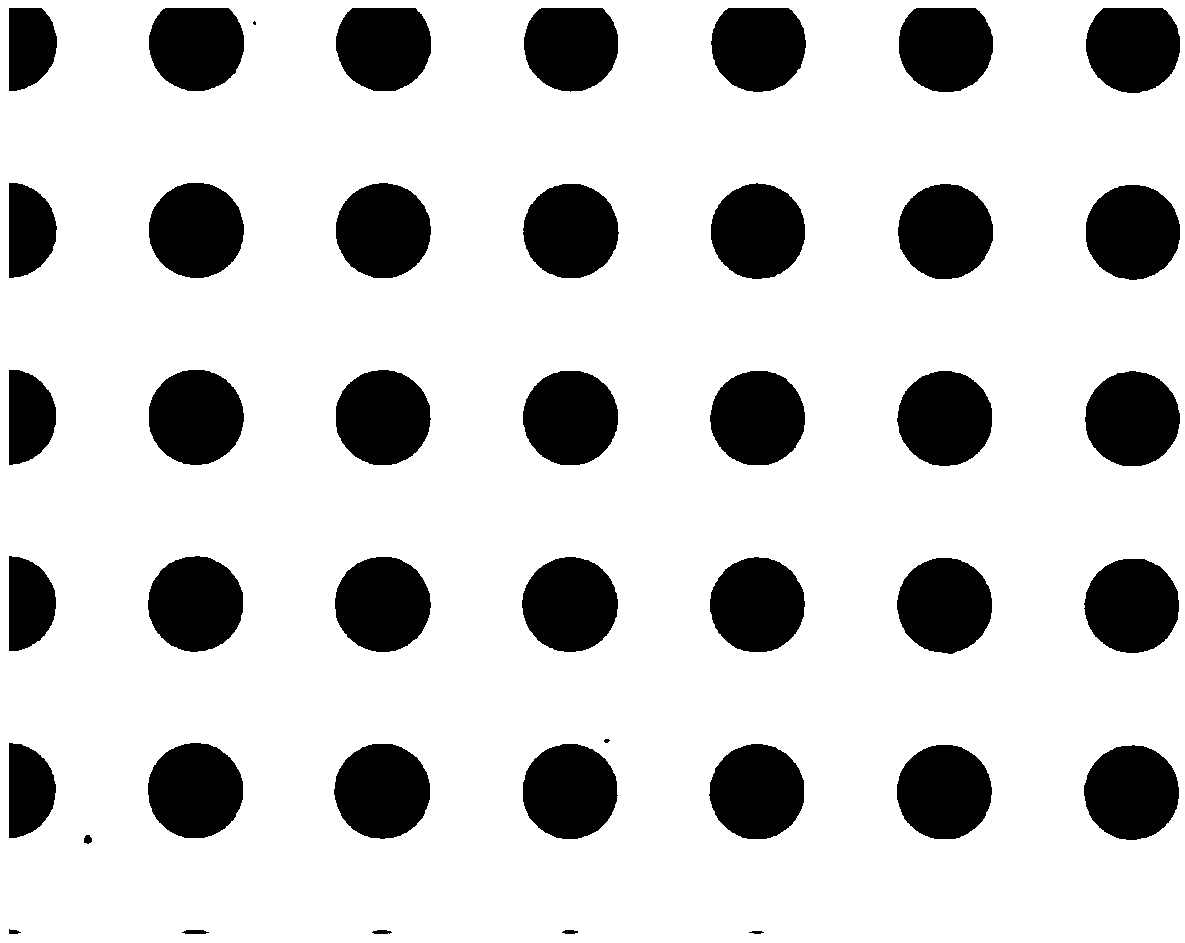

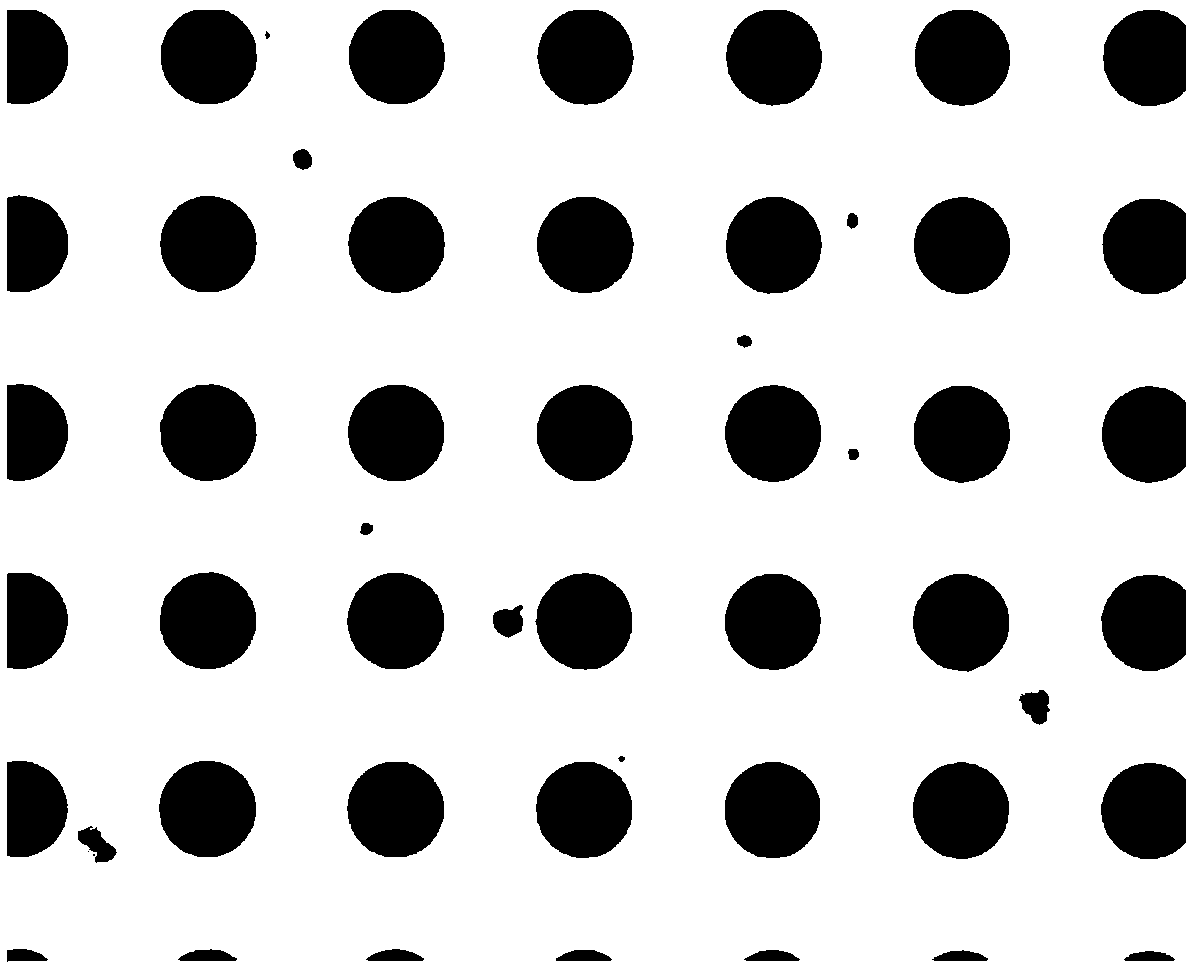

Image

Examples

Embodiment 1

[0041] A kind of photoresist plate surface damage repairing solution, comprises potassium dichromate, chromium sulfate, chromium chloride, concentrated sulfuric acid and water, potassium dichromate, chromium sulfate, chromium chloride, concentrated sulfuric acid, water account for in the repairing solution The mass percentages are 21wt.%, 4wt.%, 3wt.%, 57wt.% and 15wt.%, respectively.

Embodiment 2

[0043] A solution for repairing surface damage of a photolithographic plate, comprising potassium dichromate, chromium nitrate, concentrated sulfuric acid, and water, wherein the mass percentages of potassium dichromate, chromium nitrate, concentrated sulfuric acid, and water in the repair solution are 12wt.%, 4wt.%, 63wt.%, 21wt.%.

Embodiment 3

[0045] A kind of photolithographic plate surface damage repair solution, comprises potassium dichromate, chromium sulfate, chromium chloride, concentrated sulfuric acid, water, potassium dichromate, chromium sulfate, chromium chloride, concentrated sulfuric acid, water account for in the repair solution The mass percentages are 15wt.%, 3wt.%, 2wt.%, 58wt.%, 22wt.%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com