Degradable tofu cat litter and preparation method thereof

A technology of cat litter and tofu, applied in animal houses, applications, animal husbandry, etc., can solve the problems of pet respiratory system damage, cats defecate everywhere, cat liver damage, etc., to achieve strong water absorption and agglomeration Effect, good water absorption, effect of less equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

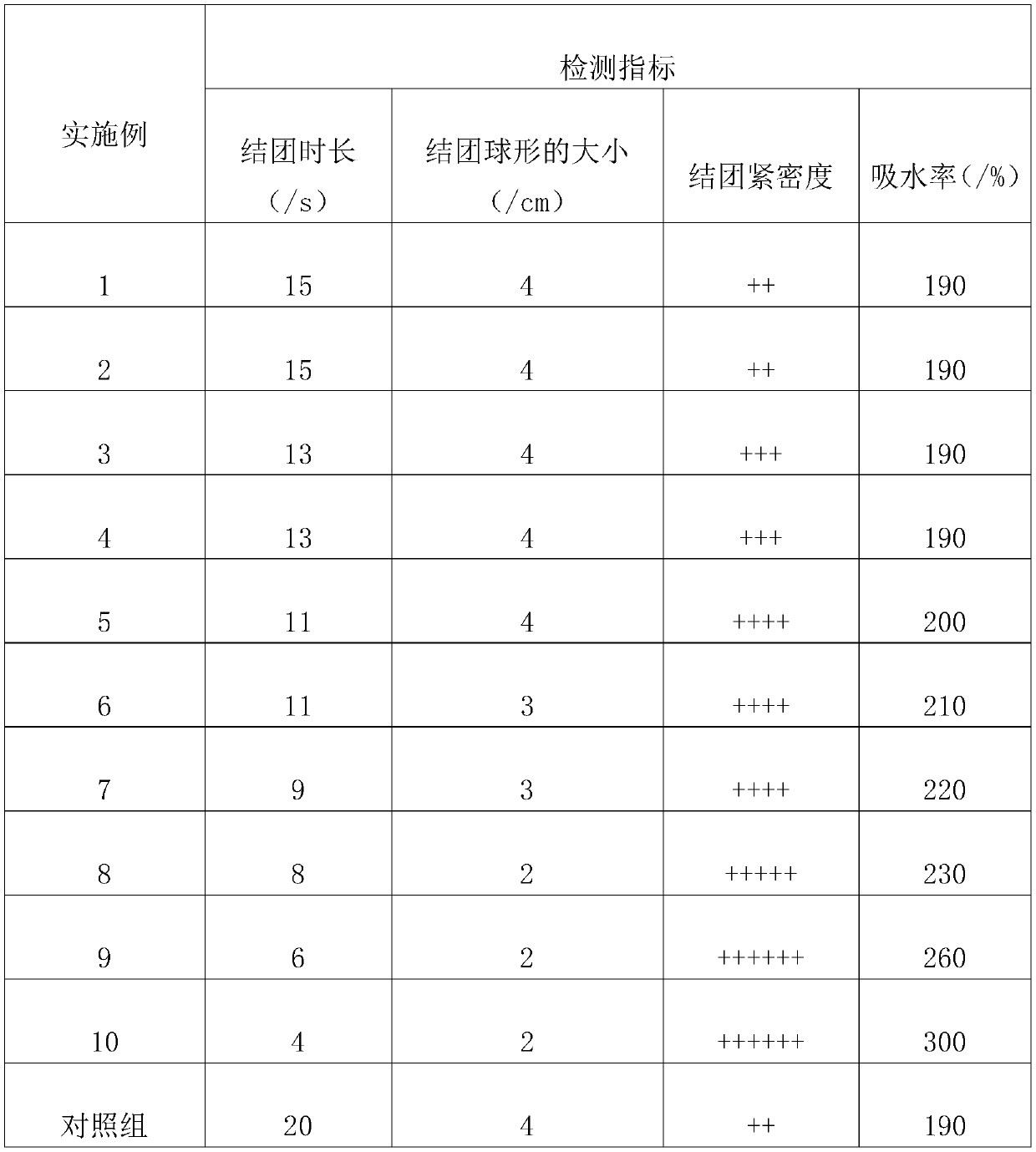

Examples

Embodiment 1

[0035] Select and weigh 10 grams of wood fiber, 10 grams of dry pea dregs powder, 20 grams of food-grade cornstarch and 5 grams of puffed corn flour, put them into a mixer and mix them evenly, then send them into the mixer through an auger and stir for 10 minutes to obtain Stirring material. Choose and weigh 0.3 gram of edible grade guar gum, 0.05 gram of potassium sorbate and 0.2 gram of water enter in the mixer and mix with stirring material through the input window of mixer, stir again 15 minutes, obtain secondary mixing material. The secondary mixing material is sent to the flat die granulator through the conveyor belt for granulation and molding. After the molded product is passed through a rolling sieve to remove the dust in the preparation process, it is sent to a cooling tower through a conveyor belt to be cooled by natural wind, and the finished product can be made after cooling to room temperature. The water content of the finished product is 10%.

Embodiment 2

[0037] Select and weigh 10 grams of wood fiber, 10 grams of dry pea dregs powder, 20 grams of food-grade cornstarch and 5 grams of puffed corn flour, put them into a mixer and mix them evenly, then send them into the mixer through an auger and stir for 50 minutes to obtain Stirring material. Choose and weigh 0.3 gram of edible grade guar gum, 0.05 gram of potassium sorbate and 0.2 gram of water enter in the mixer and mix with stirring material through the input window of mixer, stir again 45 minutes, obtain secondary mixing material. The secondary mixing material is sent to the flat die granulator through the conveyor belt for granulation and molding. After the molded product is passed through a rolling sieve to remove the dust in the preparation process, it is sent to a cooling tower through a conveyor belt for cooling by natural wind, and the finished product can be made after cooling to room temperature. The water content of the finished product is 14%.

Embodiment 3

[0039] Select and weigh 40 grams of wood fiber, 60 grams of dry soybean dregs powder, 40 grams of food-grade cornstarch and 15 grams of puffed corn flour, put into a mixer and mix evenly, then send it into the mixer through an auger and stir for 10 minutes to obtain Stirring material. Choose and weigh 3 grams of edible grade guar gum, 1 gram of potassium sorbate and 1 gram of water enter in the mixer through the input window of the mixer and mix with the mixing material, and stir again for 15 minutes to obtain the secondary mixing material. The secondary mixing material is sent to the flat die granulator through the conveyor belt for granulation and molding. After the molded product is passed through a rolling sieve to remove the dust in the preparation process, it is sent to a cooling tower through a conveyor belt to be cooled by natural wind, and the finished product can be made after cooling to room temperature. The water content of the finished product is 10%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Graininess | aaaaa | aaaaa |

| Graininess | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com