Anti-allergic high-oil hydrolyzed whey ingredient powder and production process thereof

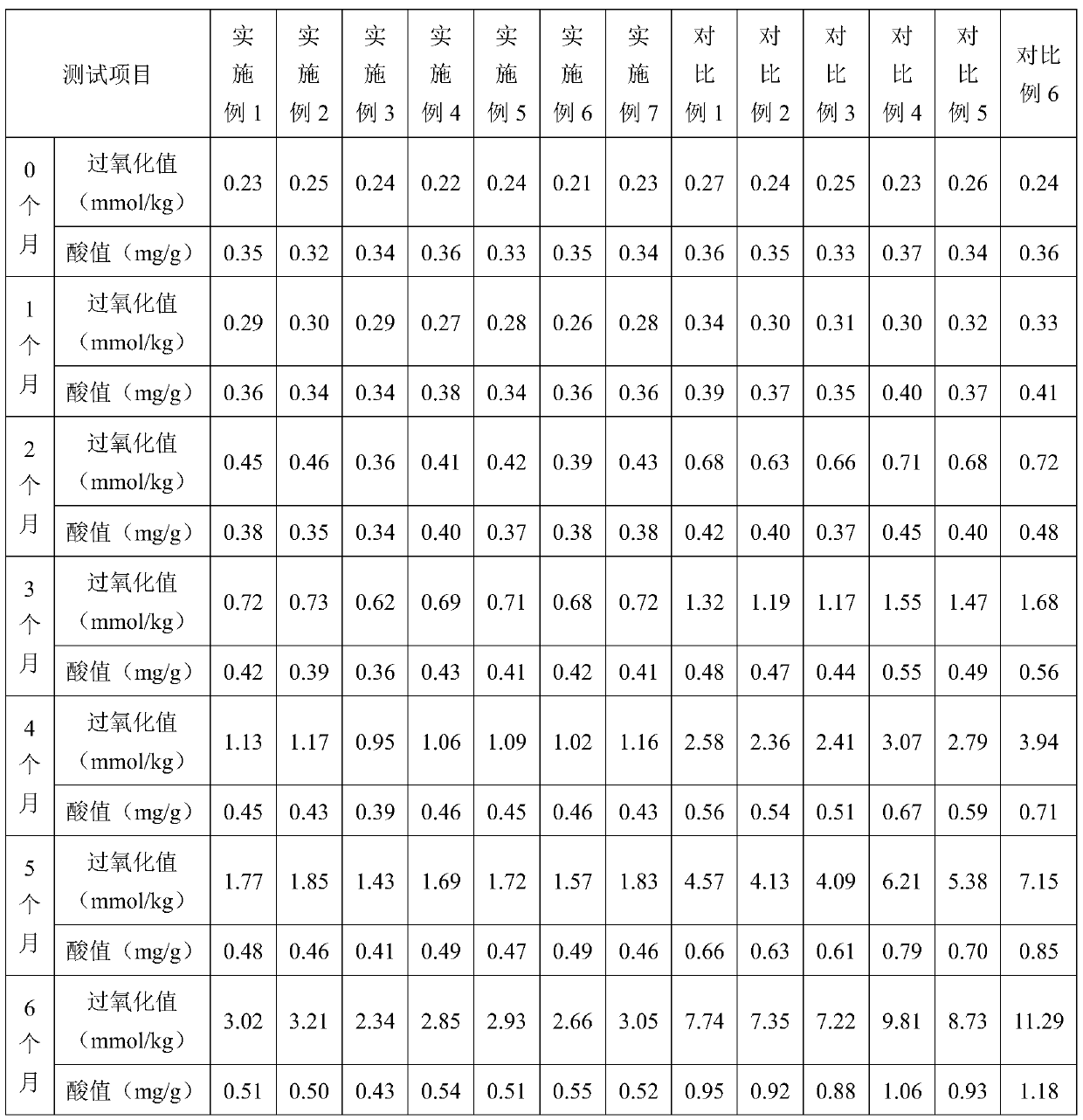

A production process and anti-allergic technology, applied in whey, dairy products, applications, etc., can solve the problems of easy oxidation of vegetable oil and poor product stability, and achieve good storage stability, little change in acid value, and improved stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] An anti-allergic high-oil hydrolyzed whey ingredient powder, comprising the following components in parts by weight:

[0035] 120 parts of desalted whey powder, 15 parts of rapeseed oil, 100 parts of soybean oil, 15 parts of medium chain triglycerides, 5 parts of 1,3-dioleic acid-2-palmitic acid triglyceride, 0.03 parts of sodium ascorbate, ascorbic acid 7 parts of palmitate, 0.015 parts of potassium hydroxide, 6 parts of fructooligosaccharide, 5 parts of compound stabilizer, 0.05 part of lactase,

[0036] Its production process includes the following steps:

[0037] A, according to the above formula, take each component for subsequent use;

[0038] B. Preheat rapeseed oil, soybean oil, medium-chain triglycerides, 1,3-dioleic acid-2-palmitic acid triglyceride, and ascorbyl palmitate to 70°C to obtain a composite oil phase; desalted milk Add the clear powder into sterile water, heat to 60°C, shear and dissolve, add complex protease, and hydrolyze for 50 minutes to obta...

Embodiment 2

[0045] An anti-allergic high-oil hydrolyzed whey ingredient powder, comprising the following components in parts by weight:

[0046] 150 parts of desalted whey powder, 30 parts of rapeseed oil, 150 parts of soybean oil, 25 parts of medium chain triglycerides, 10 parts of 1,3-dioleic acid-2-palmitic acid triglyceride, 0.05 parts of sodium ascorbate, ascorbic acid 12 parts of palmitate, 0.02 parts of potassium hydroxide, 10 parts of fructooligosaccharide, 20 parts of compound stabilizer, 0.1 part of lactase,

[0047] Its production technology is with embodiment 1;

[0048] Among them, the compound stabilizer is a mixture of lysophospholipid, lactose and quinoa powder with a mass ratio of 1:4:7; quinoa powder is obtained by washing quinoa with quinoa seeds, boiling in water for 10 minutes, cooling to room temperature, and freeze-drying; desalted milk The clear powder is D90 desalted whey powder, and the mass ratio of desalted whey powder to sterile water and compound protease is 2...

Embodiment 3

[0050] An anti-allergic high-oil hydrolyzed whey ingredient powder, comprising the following components in parts by weight:

[0051] 130 parts of desalted whey powder, 22 parts of rapeseed oil, 120 parts of soybean oil, 20 parts of medium chain triglycerides, 8 parts of 1,3-dioleic acid-2-palmitic acid triglycerides, 0.04 parts of sodium ascorbate, ascorbic acid 10 parts of palmitate, 0.018 parts of potassium hydroxide, 8 parts of fructooligosaccharide, 13 parts of compound stabilizer, 0.07 part of lactase,

[0052] Its production technology is with embodiment 1;

[0053] Among them, the compound stabilizer is a mixture of lysophospholipid, lactose and quinoa powder with a mass ratio of 1:4:7; quinoa powder is obtained by washing quinoa with quinoa seeds, boiling in water for 10 minutes, cooling to room temperature, and freeze-drying; desalted milk The clear powder is D90 desalted whey powder, and the mass ratio of desalted whey powder to sterile water and compound protease i...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap