Preparation method of fresh wet rice noodles

A rice noodle, fresh and wet technology, applied in sustainable manufacturing/processing, food preservation, packaging objects under special gas conditions, etc. The effect of avoiding easy breakage, simplifying the production process and prolonging the shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

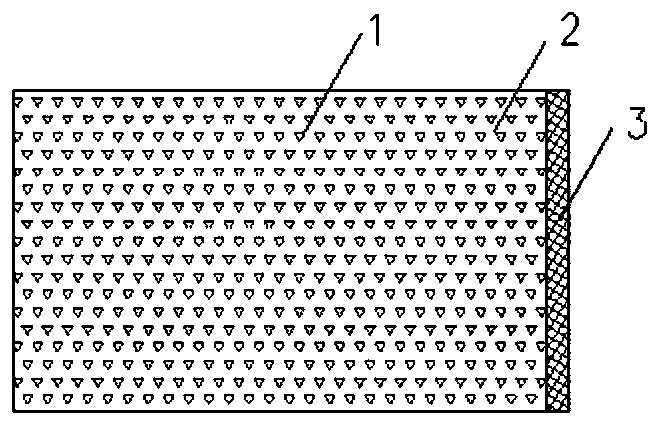

[0049] The present invention optimizes the preparation process of fresh and wet rice noodles, and at first provides a kind of draining packaging bag suitable for the production of fresh and wet rice noodles (such as figure 1 As shown), the secondary aging and thermal sterilization steps of fresh and wet rice noodles are combined into one, which simplifies the production process of fresh and wet rice noodles and makes it more conducive to factory production; at the same time, it prevents fresh and wet rice noodles from being easily broken due to repeated heating. strip phenomenon. In addition, the use of draining bags can reduce the broken bars caused by repeated bending of rice noodles.

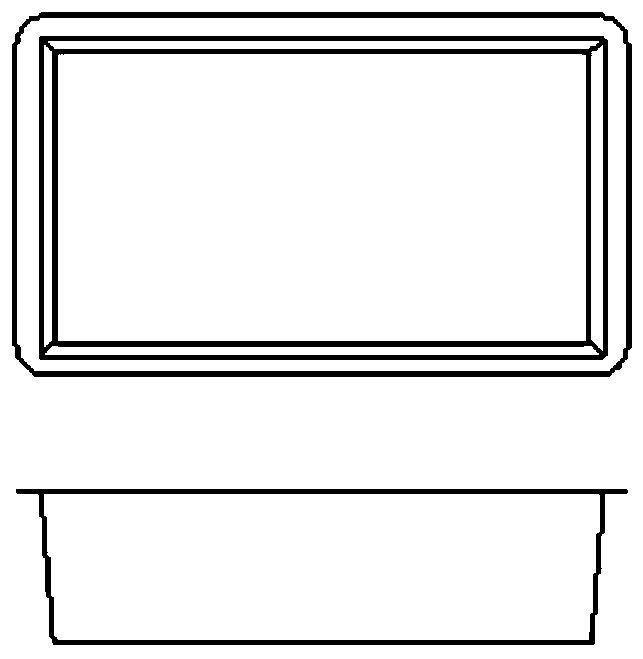

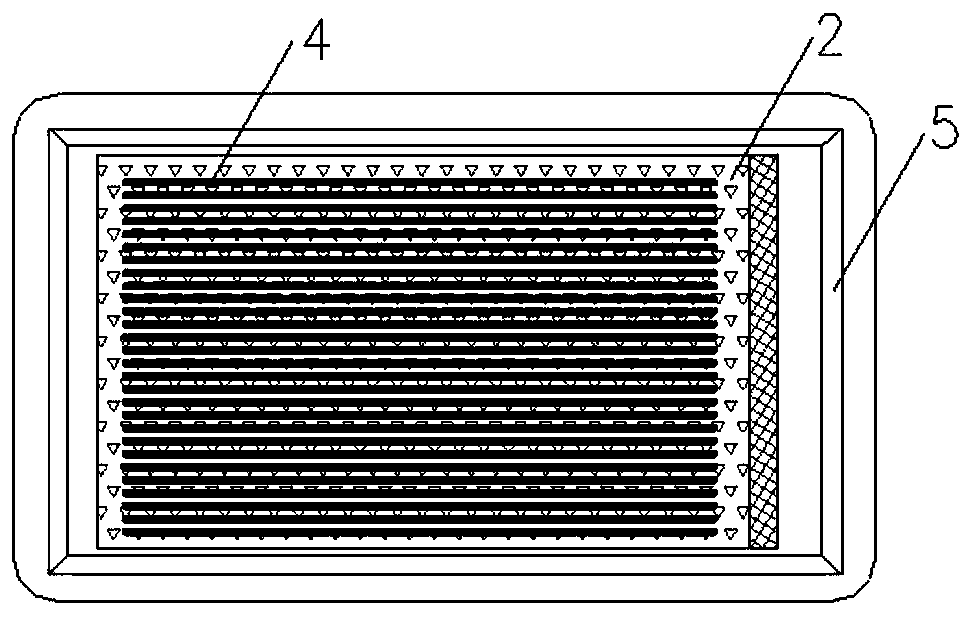

[0050] Secondly, the present invention packs the fresh wet rice noodles packed in a drained packaging bag into a modified atmosphere fresh-keeping box (such as figure 2 , 3 As shown), the use of compound gas (carbon dioxide and nitrogen) modified atmosphere preservation technology can make...

Embodiment 1

[0053] Mix 90 parts of early indica rice and 10 parts of late indica rice, soak rice, refine pulp, plate and frame press filter, dry, and pass through a 100-mesh sieve to obtain the required rice flour.

[0054] Mix 10 parts of tapioca starch, 15 parts of wheat starch, 20 parts of corn starch, 5 parts of maltodextrin and 75 parts of rice flour, adjust the moisture content to 54%, stir well, and use a self-cooking extruder The filaments were extruded, sealed and aged at 35°C for 10h. The aged rice noodles were cut to length, put into drained cooking bags and sealed, boiled in water at 100°C for 10 minutes for secondary aging and sterilization, drained and cooled, put into a modified atmosphere fresh-keeping box, and carried out modified atmosphere packaging to obtain box-packed fresh wet rice noodles.

Embodiment 2

[0056] Mix 85 parts of early indica rice and 15 parts of late indica rice, soak the rice, refine the pulp, press filter with plate and frame, dry, and pass through a 100-mesh sieve to obtain the required rice flour.

[0057] Mix 1 part of tapioca starch, 10 parts of wheat starch, 15 parts of corn starch, 1 part of maltodextrin and 80 parts of rice flour, adjust the moisture content to 52%, after stirring evenly, use a self-cooking extruder The filaments were extruded, sealed and aged at 30°C for 8h. The aged rice noodles were cut to length, put into drained and cooked bags, sealed, boiled in water at 100°C for 5 minutes for secondary aging and sterilization, drained and cooled, put into a modified atmosphere fresh-keeping box, and packaged in a modified atmosphere to obtain box-packed fresh wet rice noodles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com