Muddy eye shadow and preparation method thereof

A kind of eye shadow and mud-like technology, which is applied in the field of mud-like eye shadow and its preparation, can solve the problems of affecting product use feeling, flying powder, insufficient adhesion of materials, etc., to achieve easy coloring, reduce flying powder, and improve safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

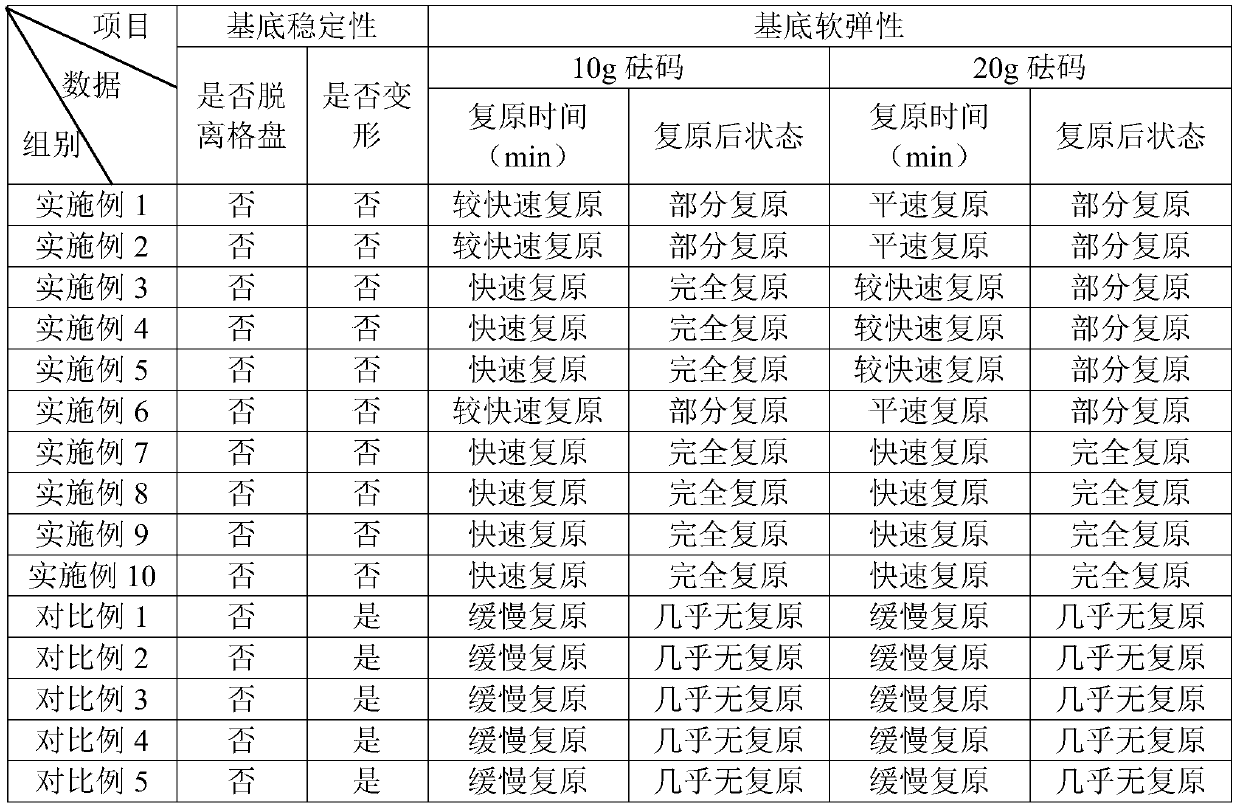

Examples

Embodiment 1-10

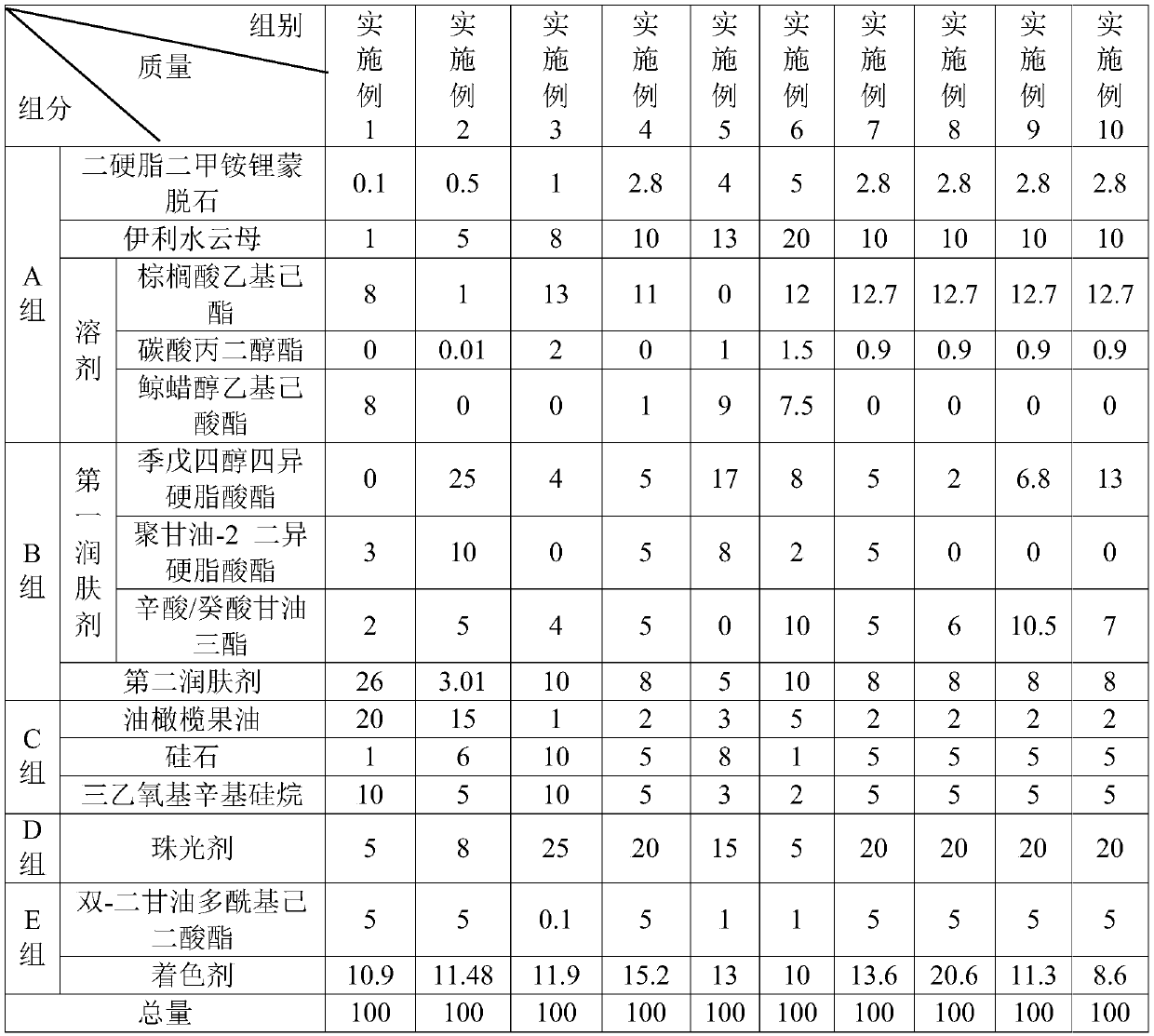

[0078] Embodiment 1-10: A kind of clay eye shadow, the components included and the corresponding quality are shown in Table 1, and are prepared by the following steps:

[0079] (1) One of the solvent components (ethylhexyl palmitate or cetyl ethylhexanoate, or ethyl palmitate if the solvent contains ethylhexyl palmitate and cetyl ethylhexanoate) Hexyl hexyl ester) and distearyl dimethyl ammonium hectorite are dropped into the agitator, stirred at a stirring speed of 1000r / min for 10min, under the condition of keeping stirring, drop into the remaining solvent components in the agitator, and continue Stir for 10 minutes, and finally add illite hydromica and continue to stir for 10 minutes to obtain mixture A;

[0080] (2) Put the first emollient and the second emollient into the melting pot, heat to 45°C, and stir for 20min under the condition of 1000r / min to obtain the mixture B;

[0081] (3) Silica and triethoxyoctylsilane are put into the stirred tank, stirred for 20min unde...

Embodiment 11

[0097] Embodiment 11: a kind of preparation method of muddy eye shadow, comprises the following steps:

[0098] (1) Mix the solvent and distearyldimethylammonium hectorite evenly, put them into the mixer, stir at a stirring speed of 1000r / min for 10min, then add illite hydromica and continue stirring for 10min, to obtain mixture A;

[0099] (2) Put the first emollient and the second emollient into the melting pot, heat to 45°C, and stir for 20min under the condition of 1000r / min to obtain the mixture B;

[0100] (3) Silica and triethoxyoctylsilane are put into the stirred tank, stirred for 20min under the condition of 200r / min, and set aside;

[0101] (4) After the mixture B was cooled to 25±5°C, the raw materials of mixture A and group C were put in, and stirred at 500r / min for 30min to obtain mixture C;

[0102] (5) Grind the coloring agent and bis-diglycerol polyacyl adipate-2 to obtain mixture D; grind through a three-roll mill, the gap between the middle and rear rolls i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com