Graphene composite material for removing formaldehyde and preparation method of graphene composite material

A composite material and graphene technology, applied in the direction of separation methods, chemical instruments and methods, carbon compounds, etc., can solve the problems that the demand for formaldehyde removal is far apart, the removal rate of formaldehyde is not ideal, etc., and achieve the effect of complete removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

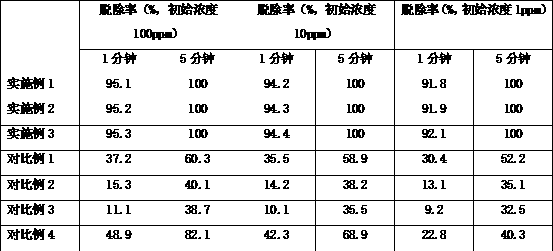

Examples

Embodiment 1

[0032] A method for preparing a formaldehyde-removing graphene composite material. First, titanium carbonitride is modified with γ-methacryloxypropyltrimethoxysilane to obtain modified titanium carbonitride, and then silicon, Boron co-doped graphene is modified with 3-aminopropyltriethoxysilane to obtain modified graphene, and finally modified titanium oxycarbonitride, modified graphene and modified silica gel are mixed and reacted to obtain the described A formaldehyde-removing graphene composite material; wherein, the modified silica gel is obtained by modifying silica gel with 3-aminopropyltrihydroxysilane.

[0033] The titanium oxycarbonitride is obtained by heating titanium carbonitride in an inert gas containing oxygen, wherein the dosages of titanium oxycarbonitride, oxygen and inert gas are 1g, 1L, and 6L respectively, and the inert gas is helium , the heating condition is: heating at 1100° C. for 7 hours.

[0034]The preparation method of modified titanium oxycarboni...

Embodiment 2

[0045] A method for preparing a formaldehyde-removing graphene composite material. Firstly, titanium carbonitride is modified with γ-methacryloxypropyltrimethoxysilane to obtain modified titanium carbonitride, and then silicon, Boron co-doped graphene is modified with 3-aminopropyltriethoxysilane to obtain modified graphene, and finally modified titanium oxycarbonitride, modified graphene and modified silica gel are mixed and reacted to obtain the described A formaldehyde-removing graphene composite material; wherein, the modified silica gel is obtained by modifying silica gel with 3-aminopropyltrihydroxysilane.

[0046] The titanium oxycarbonitride is obtained by heating titanium carbonitride in an inert gas containing oxygen, wherein the dosages of titanium oxycarbonitride, oxygen and inert gas are 1g, 1L, and 7L respectively, and the inert gas is argon , the heating condition is: heating at 1000°C for 8 hours.

[0047] The preparation method of modified titanium oxycarboni...

Embodiment 3

[0058] A method for preparing a formaldehyde-removing graphene composite material. Firstly, titanium carbonitride is modified with γ-methacryloxypropyltrimethoxysilane to obtain modified titanium carbonitride, and then silicon, Boron co-doped graphene is modified with 3-aminopropyltriethoxysilane to obtain modified graphene, and finally modified titanium oxycarbonitride, modified graphene and modified silica gel are mixed and reacted to obtain the described A formaldehyde-removing graphene composite material; wherein, the modified silica gel is obtained by modifying silica gel with 3-aminopropyltrihydroxysilane.

[0059] The titanium oxycarbonitride is obtained by heating titanium carbonitride in an inert gas containing oxygen, wherein the dosages of titanium oxycarbonitride, oxygen and inert gas are 1g, 1L, and 6.5L respectively, and the inert gas is helium gas, and the heating condition is: heating at 1050°C for 7.5 hours.

[0060] The preparation method of modified titaniu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com