A kind of brine refining scale inhibitor and dispersant and its preparation method and application

A scale inhibitor dispersant and brine technology, applied in the field of scale inhibitors, can solve the problems of low removal rate, limited use range of removal means, high removal cost, etc., achieve simple formula, ensure scale inhibition effect, and be environmentally friendly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

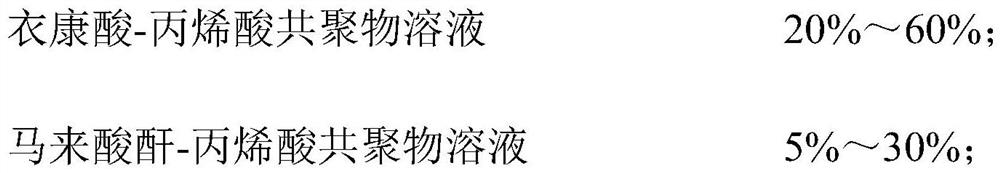

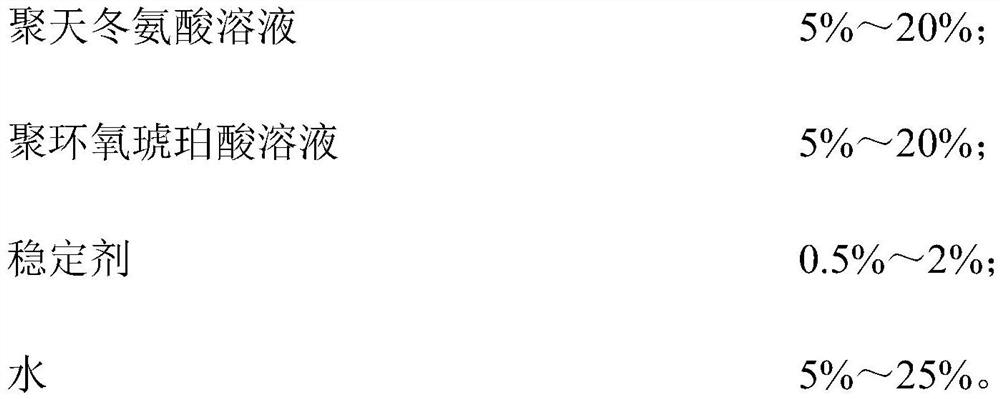

[0044] Scale inhibitor and dispersant, the composition is as follows (mass percentage):

[0045]

[0046] The aforementioned itaconic acid-acrylic acid copolymer solution is an aqueous solution with a mass fraction of 30%, the maleic anhydride-acrylic acid copolymer solution is an aqueous solution with a mass fraction of 50%, and the polyaspartic acid solution is a mass fraction of 40%. The content of succinic acid solution is 40% by mass, and the stabilizer is Na 2 SO 3 .

[0047] Preparation process: first, add 100% of the water usage to the reaction kettle, and add a stabilizer (Na 2 SO 3 ), stirred for 15min, successively added itaconic acid-acrylic acid copolymer solution, maleic anhydride-acrylic acid copolymer solution, polyaspartic acid solution, polyepoxysuccinic acid solution in proportion, and stirred for 15min to obtain the brine refining scale inhibition Dispersant. All operations were performed at room temperature.

[0048] Experimental research results:...

Embodiment 2-6

[0132] Based on the research on the mixing ratio of the four raw materials in Test 2.9, it was found that the itaconic acid-acrylic acid copolymer solution, the maleic anhydride-acrylic acid copolymer, the polyaspartic acid solution, and the polyepoxysuccinic acid solution When the mass ratio of raw materials is 4:2:1:0.5~1.5, the scale inhibition rate reaches more than 77%, and when the raw material ratio is 4:2:1:1, the maximum scale inhibition rate is 81.98. Example 2-6 also studied the influence of other proportions on the scale inhibition rate performance of the product. The preparation process of the scale inhibitor and dispersant in Example 2-6, the total mass of the scale inhibitor and dispersant, the mass content of the stabilizer, and the quality of the water were the same. The content is the same as in test 2.9, only the mass ratio, mass ratio and scale inhibition of itaconic acid-acrylic acid copolymer solution, maleic anhydride-acrylic acid copolymer, polyaspartic ...

Embodiment 7

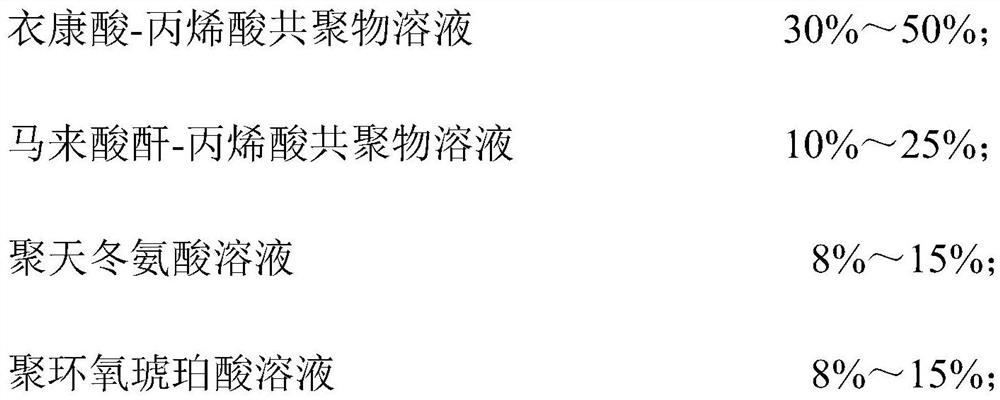

[0137] Brine refining scale inhibitor and dispersant, the composition is as follows (mass percentage):

[0138]

[0139]

[0140] The aforementioned itaconic acid-acrylic acid copolymer solution is an aqueous solution with a content of 33%, the maleic anhydride-acrylic acid copolymer is an aqueous solution with a content of 48%, the polyaspartic acid solution is an aqueous solution with a content of 41%, and the polyepoxysuccinic acid solution has a content of 40%, stabilizer is Na 2 SO 3 .

[0141]Preparation process: first, add 100% of the water usage to the reaction kettle, and add a stabilizer (Na 2 SO 3 ), stirred for 12min, successively added itaconic acid-acrylic acid copolymer solution, maleic anhydride-acrylic acid copolymer, polyaspartic acid solution, polyepoxysuccinic acid solution in proportion, and stirred for 15min to obtain the brine refining scale inhibition dispersion agent. All operations were performed at room temperature.

[0142] Measure 0.032...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| scale inhibition rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com