Modified activated carbon composite material for negative electrode of lead-carbon battery, preparation method of modified activated carbon composite material, and lead-carbon battery

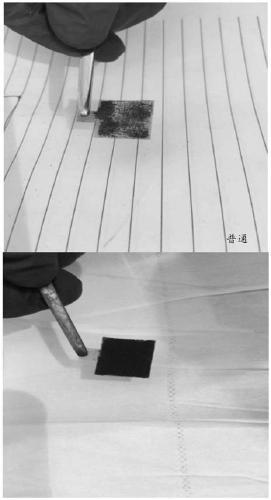

A composite material and activated carbon technology, applied in lead-acid battery electrodes, battery electrodes, lead-acid batteries, etc., can solve the problems of low content, insignificant effect, and not fully applied hydrogen evolution inhibitor, and achieve the improvement of hydrogen evolution potential without difficulty. The effect of falling off and binding tightly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0061] The present invention also provides a kind of preparation method of activated carbon composite material, comprises the following steps:

[0062] 1) Mix activated carbon, acid and solvent, and perform modification reaction to obtain modified activated carbon;

[0063] 2) Grinding the modified activated carbon obtained in the above steps to obtain an activated carbon composite material.

[0064] In the present invention, the selection, composition and structure of the materials in the above-mentioned preparation method, as well as the corresponding optimization principles, can preferably correspond to the selection, composition and structure of the aforementioned activated carbon composite materials, and the corresponding optimization principles, and will not be repeated here. A repeat.

[0065] In the invention, the activated carbon, the acid and the solvent are firstly mixed, and after modification reaction, the modified activated carbon is obtained.

[0066] In princ...

Embodiment 1

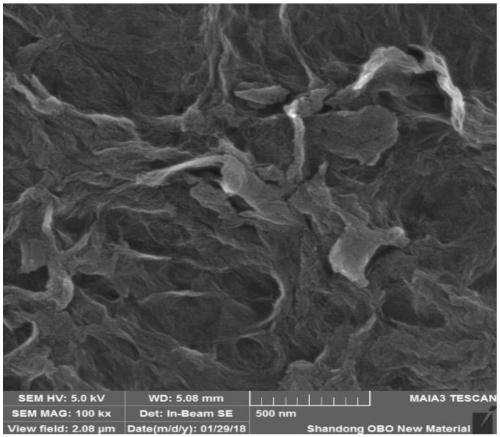

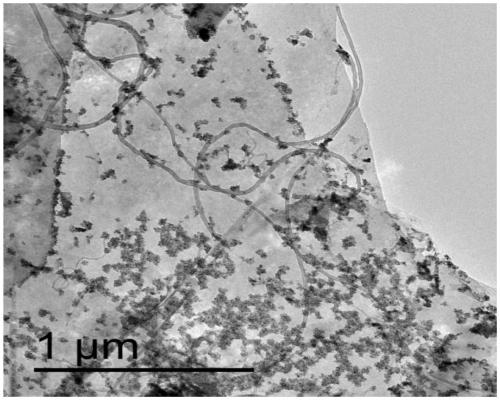

[0095] Take 500 g of Haike petroleum coke, put it into a rotary furnace for high-temperature carbonization, raise it to 800 °C at a rate of 10 °C / min, and treat it at high temperature for 60 min in a nitrogen atmosphere to obtain initial activated carbon. Put the initial activated carbon into the nickel pot, mix with 80g potassium hydroxide, mix evenly and send it to the tube furnace for high temperature treatment, N 2 Under the atmosphere, the temperature was also increased to 800°C at a rate of 10°C / min, and the reaction was maintained at 800°C for 1h.

[0096] The obtained porous carbon was washed with water, acid-washed, washed with water to pH 7-8, acid-washed, stirred in 5% HCl for 2 hours, washed with suction to neutrality, and vacuum-dried at 120° C. for 24 hours to obtain a sample. Put the sample into a mixture of alcohols and dilute nitric acid, the solution is about 1L, mix well, then modify the reaction at 80-130°C for more than 2 hours, filter and dry to obtain mo...

Embodiment 2

[0112] Take 500 g of Haike petroleum coke, put it into a rotary furnace for high-temperature carbonization, raise it to 800 °C at a rate of 10 °C / min, and treat it at high temperature for 60 min in a nitrogen atmosphere to obtain initial activated carbon. Put the initial activated carbon into the nickel pot, mix with 80g potassium hydroxide, mix evenly and send it to the tube furnace for high temperature treatment, N 2 Under the atmosphere, the temperature was also increased to 800°C at a rate of 10°C / min, and the reaction was maintained at 800°C for 1h.

[0113] The obtained porous carbon was washed with water, acid-washed, washed with water to pH 7-8, acid-washed, stirred in 5% HCl for 3 hours, washed with suction to neutrality, and vacuum-dried at 120° C. for 24 hours to obtain a sample. Put the sample into the mixed solution of alcohols and dilute nitric acid, the solution is about 1L, mix well, then modify the reaction at 80-130℃ for more than 3 hours, filter and dry to o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com