A lead-acid battery negative lead paste for suppressing hydrogen evolution and preparation method thereof

A technology of lead-acid batteries and negative electrode paste, which is applied to battery electrodes, circuits, electrical components, etc., and can solve problems such as increased water consumption, increased explosions, and other unsafe events

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

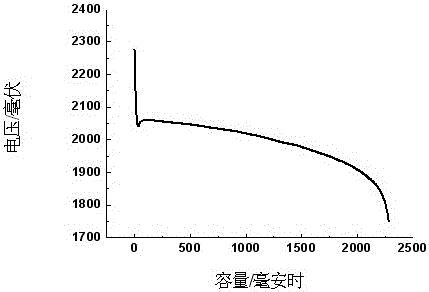

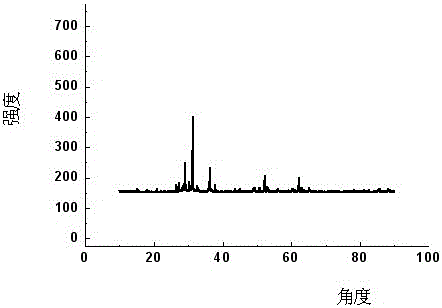

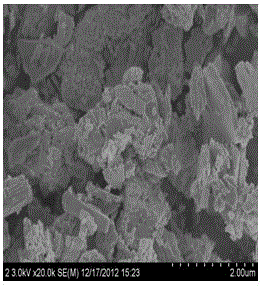

Image

Examples

Embodiment 1

[0023] Example 1, the following negative electrode paste raw materials were weighed: 1000 g of lead powder, 10 g of graphite, 5 g of carbon black, 1.5 g of zinc oxide, 3 g of barium sulfate, 1 g of sodium lignosulfonate, and 0.1 g of fiber.

Embodiment 2

[0024] Embodiment 2, take by weighing the following negative electrode lead paste raw materials: lead powder 1000g, carbon black 10g, superconducting carbon black 15g, zinc oxide 3g, zinc sulfide 1.5g, barium sulfate 10g, sodium lignosulfonate 5g, fiber 5g.

Embodiment 3

[0025] Example 3, the following negative electrode paste raw materials were weighed: 1000 g of lead powder, 10 g of graphite, 15 g of carbon black, 5 g of acetylene black, 5 g of zinc oxide, 20 g of barium sulfate, 4 g of sodium lignosulfonate, and 3 g of fiber.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com