Aqueous resin composition, laminated body and article employing same

A technology of water-based resin and composition, applied in the direction of synthetic resin layered products, layered products, flexible coverings, etc., can solve the problems of poor adhesion of magnetic coatings, etc., and achieve the effect of good ink adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

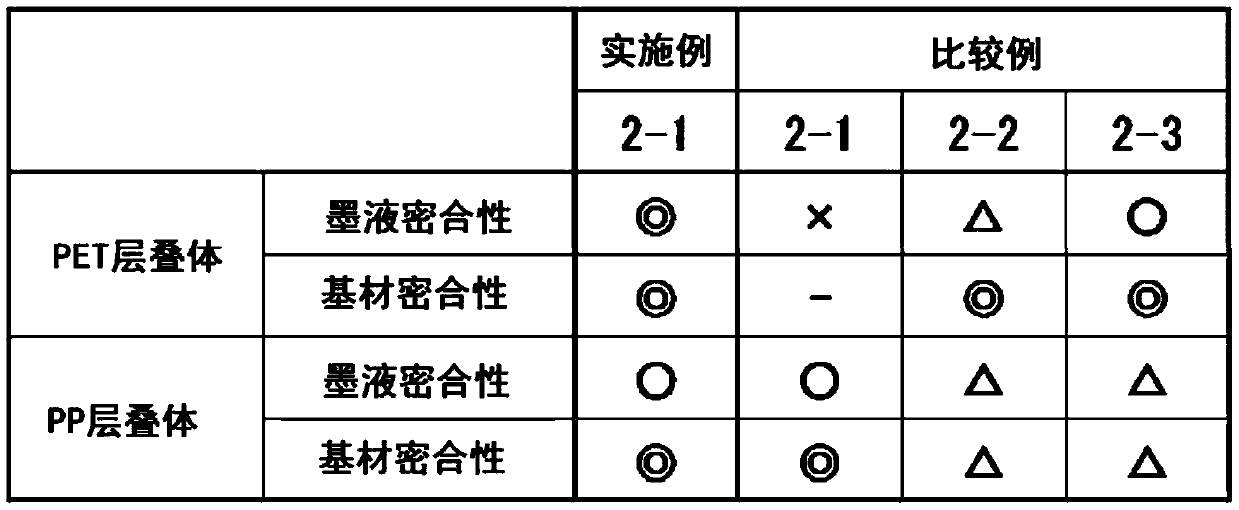

Examples

Embodiment

[0095] Hereinafter, the present invention will be described more specifically with reference to examples.

Synthetic example 1

[0096] (Synthesis Example 1: Synthesis of Polyester Polyol (1))

[0097] Into a reaction vessel equipped with a thermometer, a nitrogen introduction tube, and a stirrer, while introducing nitrogen, 35.4 parts of isophthalic acid, 17.8 parts of sebacic acid, 7.8 parts of adipic acid, 6.2 parts of ethylene glycol, neopentyl glycol 22.9 parts, 11.7 parts of 1,6-hexanediol, and 0.03 parts of dibutyltin oxide were subjected to polycondensation reaction at 230°C for 24 hours until the acid value became 1 or less at 180-230°C to obtain polyester polyol (1) [number average molecular weight 2100, acid value 0.6mgKOH / g, hydroxyl value 42.5mgKOH / g, aromatic ring concentration 2.51mol / kg].

manufacture example 1

[0098] (Manufacturing example 1: Synthesis of carboxyl group-containing polyurethane resin (I) composition)

[0099] 69.0 parts by mass of polyester polyol (1) of Synthesis Example 1 was dehydrated at 100° C. under reduced pressure in a reaction vessel, and after cooling to 80° C., 93.30 parts by mass of methyl ethyl ketone was added thereto, and stirred and uniformly mixed. Next, add 3.0 parts by mass of 1,4-butanediol, 6.1 parts by mass of 2,2'-dimethylolpropionic acid, and then add 19.4 parts by mass of toluene diisocyanate, react at 80°C for 12 hours, and implement carbamic acid Esterification process. After confirming that the isocyanate value has become 0.1% or less, 0.3 parts by mass of n-butanol was added, and after further reaction for 2 hours, it was cooled to 50° C. to obtain a carboxyl group-containing polyurethane resin (I )combination.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com