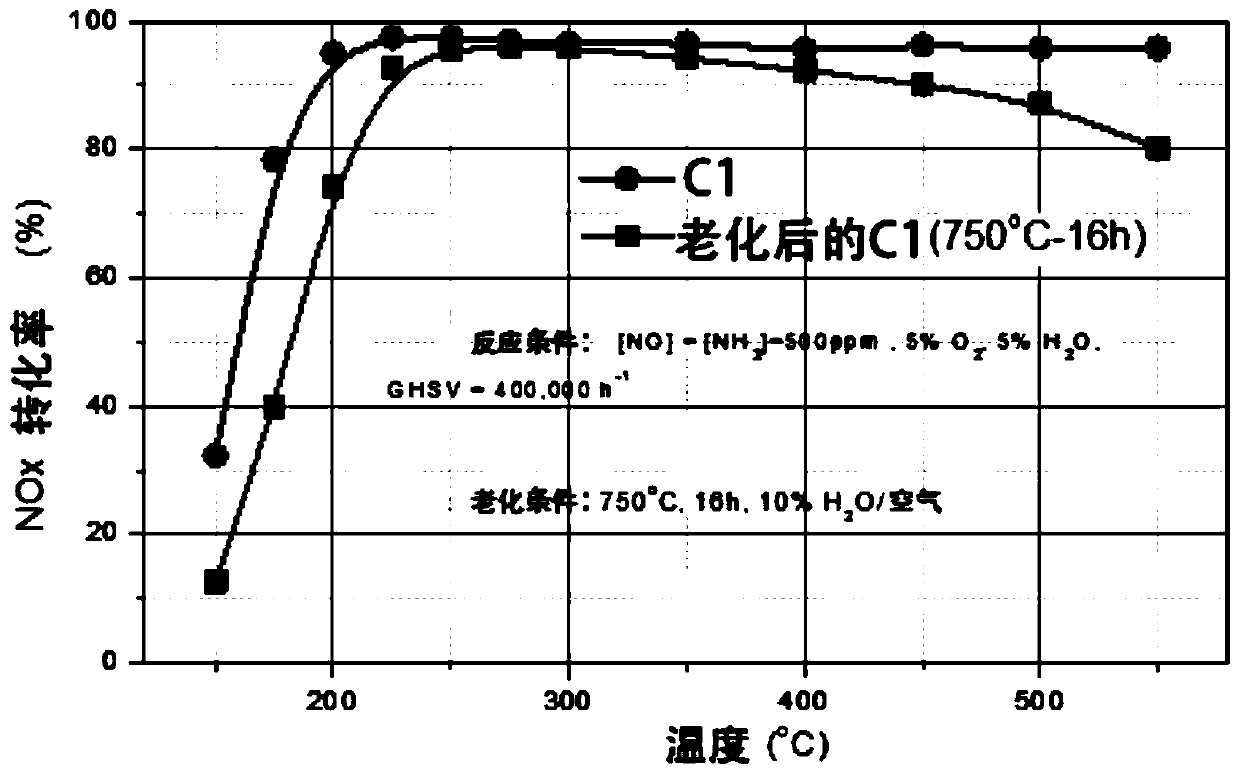

Cu-SSZ-13 catalyst and H-SSZ-13 molecular sieve with double aluminum centers and preparation methods and application thereof

A technology of cu-ssz-13 and molecular sieve, which is applied in the direction of catalyst activation/preparation, chemical instruments and methods, separation methods, etc., can solve the problems of unfavorable adsorption activation, high preparation cost, poor catalytic activity and heat resistance, and achieve excellent Catalytic activity, improved dispersion, and strong controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] As previously mentioned, the second aspect of the present invention provides a kind of preparation method that aforementioned CHA cage has the Cu-SSZ-13 catalyst of double aluminum center, and this method comprises:

[0034] (1) mixing and aging the first solvent, the first silicon source, the first aluminum source, the first alkali source, the first copper source and diethylenetriamine in sequence to obtain a directing agent solution,

[0035] (2) Contacting the second solvent, the second silicon source, the second aluminum source and the second alkali source, and adding the directing agent solution to the contact product, and then crystallizing, filtering and drying the resulting mixture in sequence ,

[0036] Wherein, in step (1), the consumption of the first solvent, the first silicon source, the first aluminum source, the first alkali source, the copper source and diethylenetriamine makes in the directing agent solution, the first solvent: SiO 2 :Al 2 o 3 : Na ...

Embodiment 1

[0076] (1) Preparation of directing agent solution

[0077] Dissolve 3.6g of sodium metaaluminate in 60g of water, add 25g of NaOH to it, stir at 25°C for 30min, add 135g of water glass, 20g of DETA, stir at 25°C for 1h, then add 16g of CuSO to the resulting solution 4 , stirred at a temperature of 25° C. for 3 hours, kept at a temperature of 25° C. and aged for more than 24 hours.

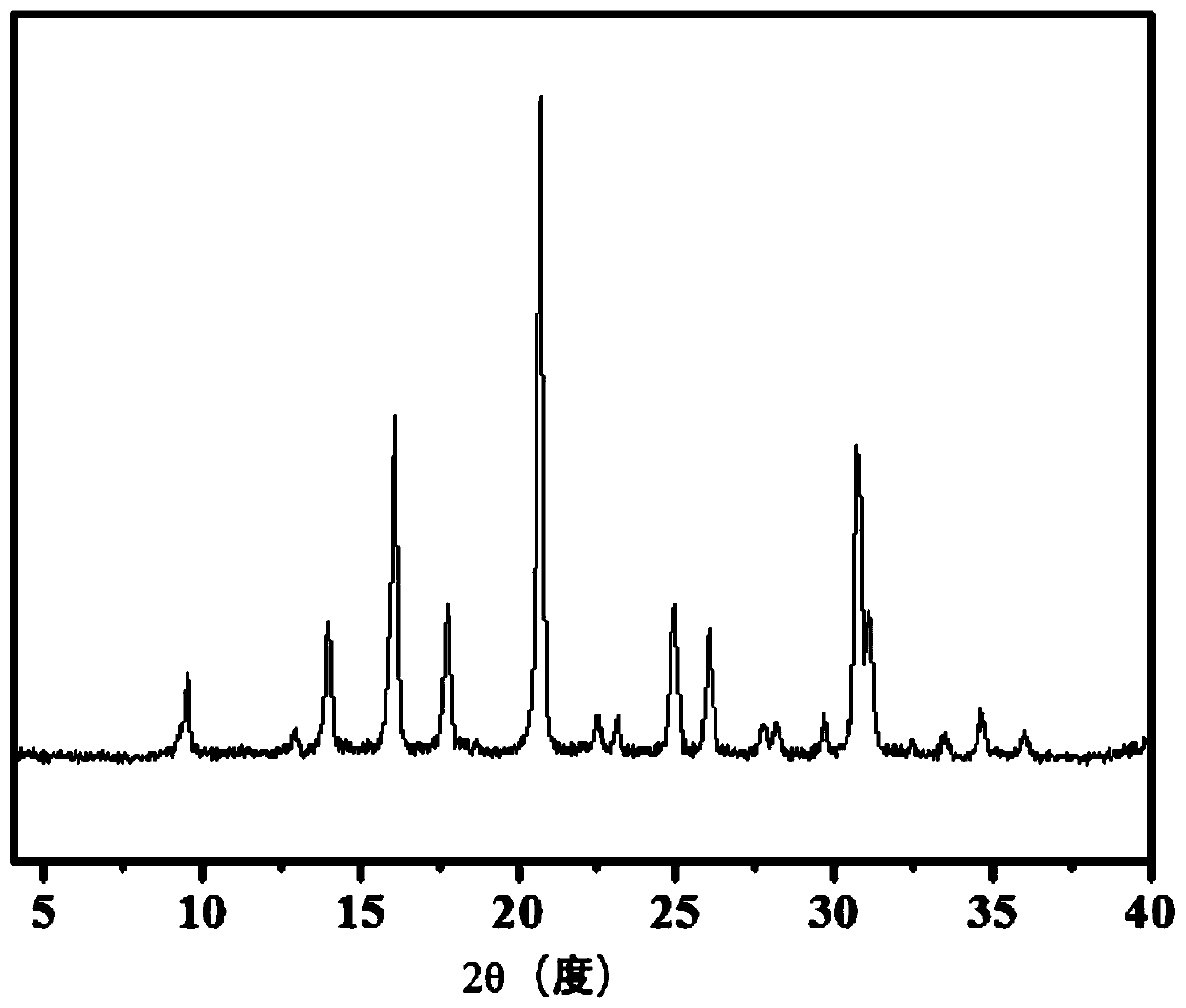

[0078] (2) Preparation of Cu-SSZ-13 catalyst with double aluminum center in CHA cage

[0079] At 25°C, 4g H 2 O, 0.03g NaOH, 0.65g sodium metaaluminate and 3.32g silica sol were placed in a beaker and mixed, and then 1% by weight of the aforementioned directing agent solution was added to the resulting mixture, and stirred for 3h at a temperature of 25°C. The gel was obtained, and then the gel was added to a polytetrafluoroethylene stainless steel reaction kettle, and crystallized at 140°C for 2 days. The sample was completely crystallized, and the obtained crystallized product was suction-filte...

Embodiment 2

[0084] (1) Preparation of directing agent solution

[0085] Dissolve 4g of sodium metaaluminate in 60g of water, add 30g of NaOH to it, stir at 35°C for 10min, add 135g of water glass, 30g of DETA, stir at 35°C for 30min, then add 24g of CuSO to the resulting solution 4 , stirred at a temperature of 35°C for 4h, and kept at a temperature of 35°C for static aging for more than 32h for later use.

[0086] (2) Preparation of Cu-SSZ-13 catalyst with double aluminum center in CHA cage

[0087] At 35°C, 2.5g H 2 O, 0.08g NaOH, 0.26g sodium metaaluminate and 3.32g white carbon black were placed in a beaker and mixed, then 1% by weight of the aforementioned directing agent solution was added to the resulting mixture, and stirred for 3h at a temperature of 35°C , to obtain a gel, and then add this gel into a polytetrafluoroethylene stainless steel reaction kettle, crystallize at 160 ° C for 12 hours, the sample is completely crystallized, filter the crystallized product obtained, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com