Stone-face-like sesame color system water permeable brick and preparation method thereof

A permeable brick and sesame technology, applied in the field of building materials, can solve the problems of permeable brick durability, strength and poor water permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

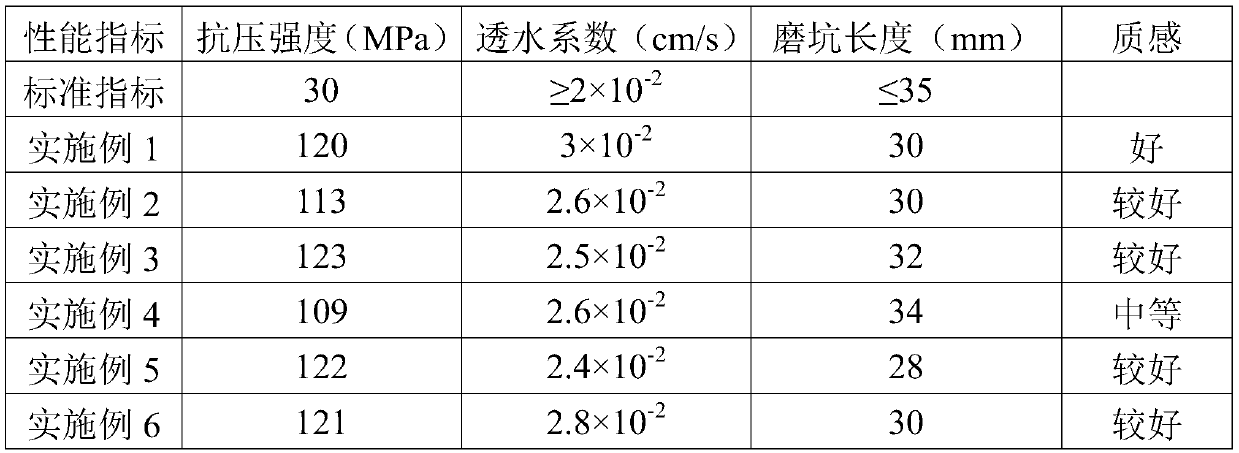

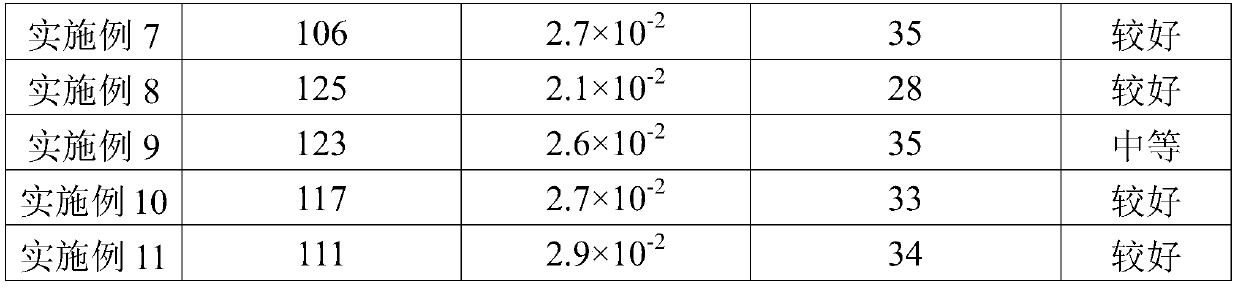

Examples

preparation example Construction

[0021] The preparation method of the sesame color permeable brick with imitation stone surface comprises the following steps:

[0022] 1) Configure the base material and fabric according to the ratio.

[0023] 2) Mixing materials: vibrate and stir the stones required for the bottom material and the Portland cement conveyed by the screw conveyor, add water and the cementing material and mix them, and then send them to the molding machine through the belt conveyor; The white silica and black silica need to be mixed evenly, vibrate and stir with the white cement conveyed by the screw conveyor, add water and cement and mix and send it to the fabric machine through the belt conveyor.

[0024] 3) The base material is pressed into the required shape by the forming machine to form a blank, which is transported to the fabric machine, and pressed with the mixed fabric to form a shaped brick.

[0025] 4) Curing: Curing the molded bricks in a natural environment for 30 days.

Embodiment 1

[0028] This embodiment provides a sesame-colored permeable brick with imitation stone surface, and its preparation method includes the following steps:

[0029] 1) Configure base material and fabric according to the following ratio:

[0030] Base material: 500kg of stones, 100kg of Portland cement, 21kg of water, 1kg of hydroxypropyl methylcellulose, 1.5kg of latex powder and 2.5kg of silica fume.

[0031] Fabric configuration: white silica 310kg, black silica 90kg, white cement 80kg, water 20.5kg, hydroxypropyl methylcellulose 0.8kg, latex powder 1.2kg, silicon powder 2kg, curing agent 2.5kg.

[0032] 2) Mixing: vibrate and stir the stones required for the bottom material and the Portland cement conveyed by the screw conveyor, add water, 1kg of hydroxypropyl methylcellulose, 1.5kg of latex powder and 2.5kg of silica fume After the mixing is completed, it is sent to the molding machine through the belt conveyor; the white silica and black silica required for the fabric are mi...

Embodiment 2

[0036] This embodiment provides a sesame-colored permeable brick with imitation stone surface, and its preparation method includes the following steps:

[0037] 1) Configure base material and fabric according to the following ratio:

[0038] Base material: 400kg of gravel, 100kg of Portland cement, 19kg of water, 0.8kg of hydroxypropyl methylcellulose, 1.2kg of latex powder and 2kg of silicon powder.

[0039] Fabric configuration: white silica 279kg, black silica 81kg, water 18.5kg, white cement 60kg, hydroxypropyl methylcellulose 0.8kg, latex powder 1.2kg, silicon powder 2kg, curing agent 2.5kg.

[0040] 2) Mixing: vibrate and stir the stones required for the bottom material and the portland cement conveyed by the screw conveyor, add water, 0.8kg of hydroxypropyl methylcellulose, 1.2kg of latex powder and 2kg of silica fume After the mixing is completed, it is sent to the molding machine through the belt conveyor; the white silica and black silica required for the fabric are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com