Technology for separating tetrahydrofuran-methanol-water through three-tower batch distillation

A technology for tetrahydrofuran and rectification separation, which is applied in distillation separation, separation method, fractionation and other directions, can solve problems such as increasing process separation load, achieve effective separation and extraction, reduce energy consumption, and ensure the effect of separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

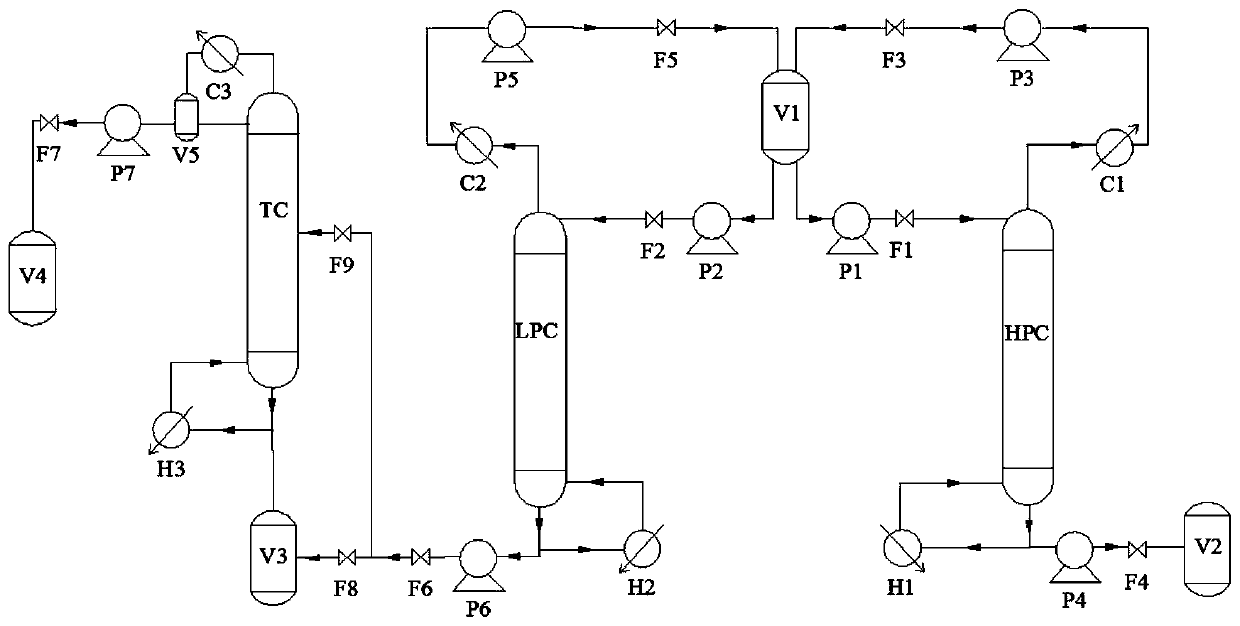

Image

Examples

Embodiment 1

[0044] Add 5500kg THF-methanol-water raw material solution with 70% THF and 15% methanol into the raw material tank V1, and part of the raw material liquid enters the rectification column HPC through the delivery pump P1 and valve F1. The number of HPC plates in the rectification column is 30 plates, the feed position is the second plate, the operating pressure is 4atm, the temperature at the top of the column is 106.6°C, and the temperature at the bottom of the column is 117.5°C. Part of the raw material in the raw material tank V1 enters the rectification column LPC through the delivery pump P2 and the valve F2. The number of LPC plates in the rectification column is 30 plates, the feed position is the second plate, the operating pressure is 0.5 atm, the temperature at the top of the tower is 43.5°C, and the temperature at the bottom of the tower is 89.6°C. The bottom of the rectification tower LPC extracts high-purity water during the water extraction stage, and enters the ...

Embodiment 2

[0046] Add 6000kg THF-methanol-water raw material solution with 71% THF and 14% methanol into the raw material tank V1, and part of the raw material liquid enters the rectification column HPC through the delivery pump P1 and valve F1. The number of HPC plates in the rectification column is 30 plates, the feed position is the second plate, the operating pressure is 9atm, the temperature at the top of the column is 138.8°C, and the temperature at the bottom of the column is 154.6°C. Part of the raw material in the raw material tank V1 enters the rectification column LPC through the delivery pump P2 and the valve F2. The number of LPC plates in the rectification column is 30 plates, the feed position is the second plate, the operating pressure is 1 atm, the temperature at the top of the column is 61.9°C, and the temperature at the bottom of the column is 102.8°C. The bottom of the rectification tower LPC extracts high-purity water during the water extraction stage, and enters the...

Embodiment 3

[0048] Add 5800kg of THF-methanol-water raw material solution with 70% THF and 16% methanol into the raw material tank V1, and part of the raw material liquid enters the rectification column HPC through the delivery pump P1 and valve F1. The number of HPC plates in the rectification column is 30 plates, the feed position is the second plate, the operating pressure is 5 atm, the temperature at the top of the column is 114.5°C, and the temperature at the bottom of the column is 126.9°C. Part of the raw material in the raw material tank V1 enters the rectification column LPC through the delivery pump P2 and the valve F2. The number of LPC plates in the rectification column is 30 plates, the feed position is the second plate, the operating pressure is 1 atm, the temperature at the top of the tower is 48.2°C, and the temperature at the bottom of the tower is 92.8°C. The bottom of the rectification tower LPC extracts high-purity water during the water extraction stage, and enters th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com