Olefin-benzoxazine copolymer oligomer, cross-linked resin and preparation method thereof

A technology of benzoxazine and cross-linking resin, which is applied in the directions of printed circuit parts, printed circuits, circuit substrate materials, etc., can solve the problems such as the inability to adjust the proportion of components in a large range, and the compatibility of resins is easy to appear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

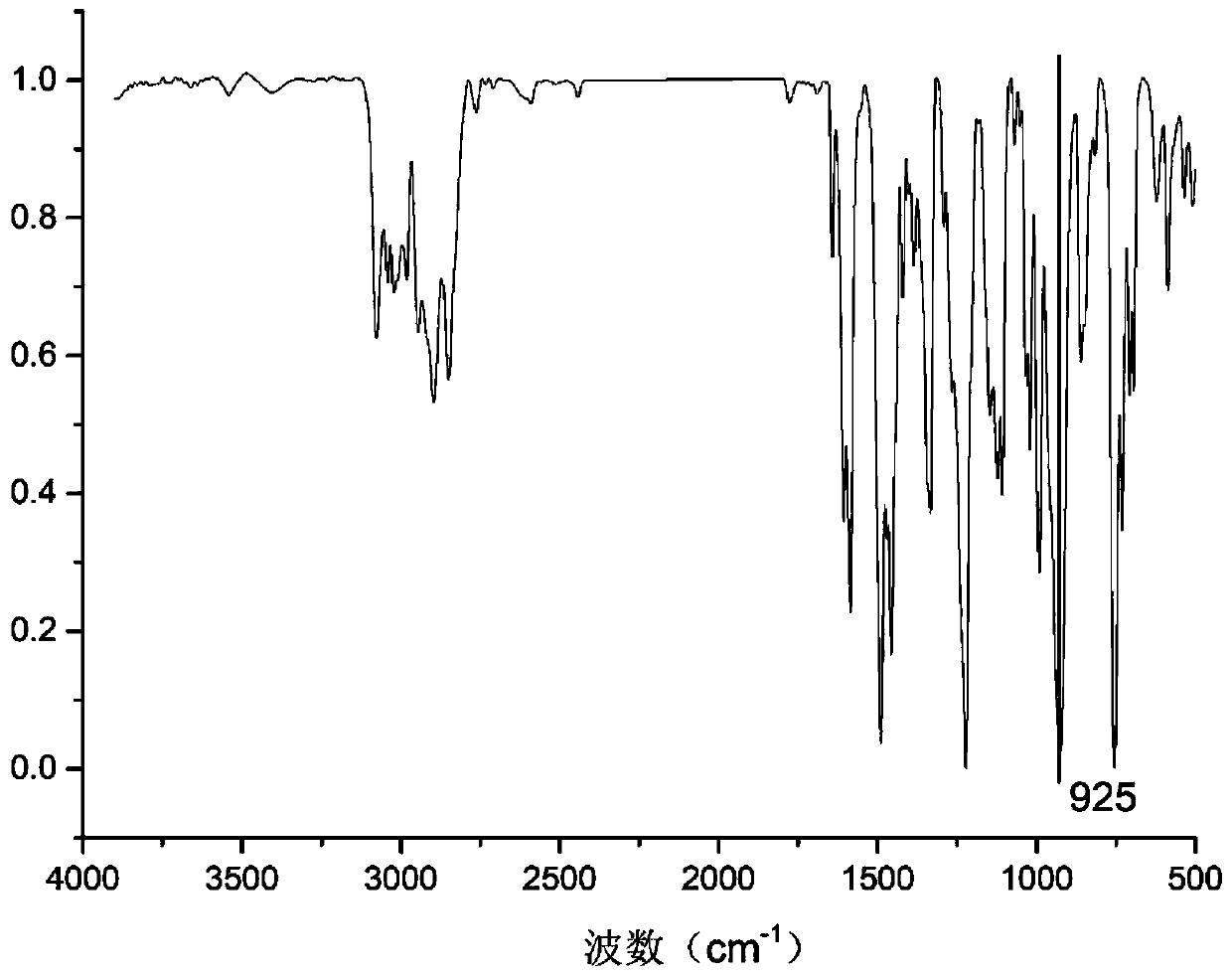

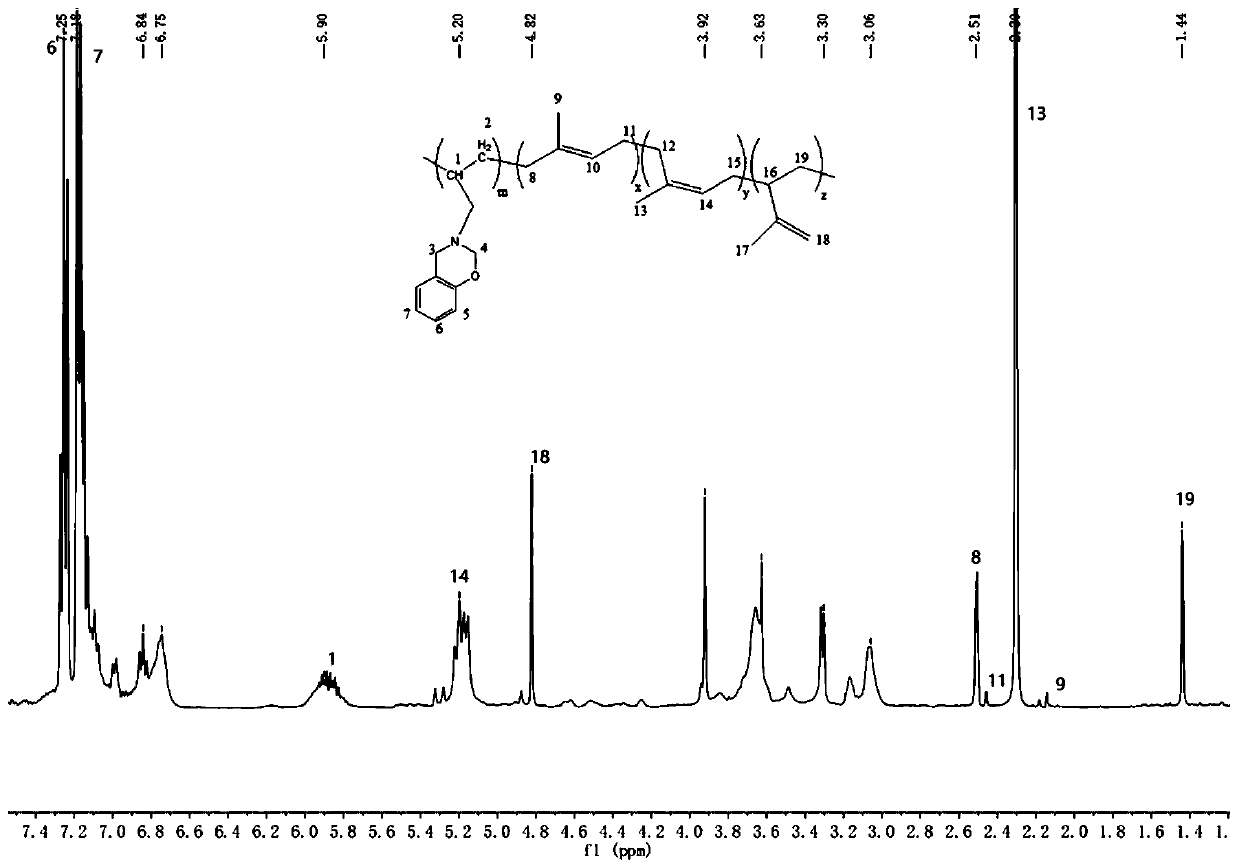

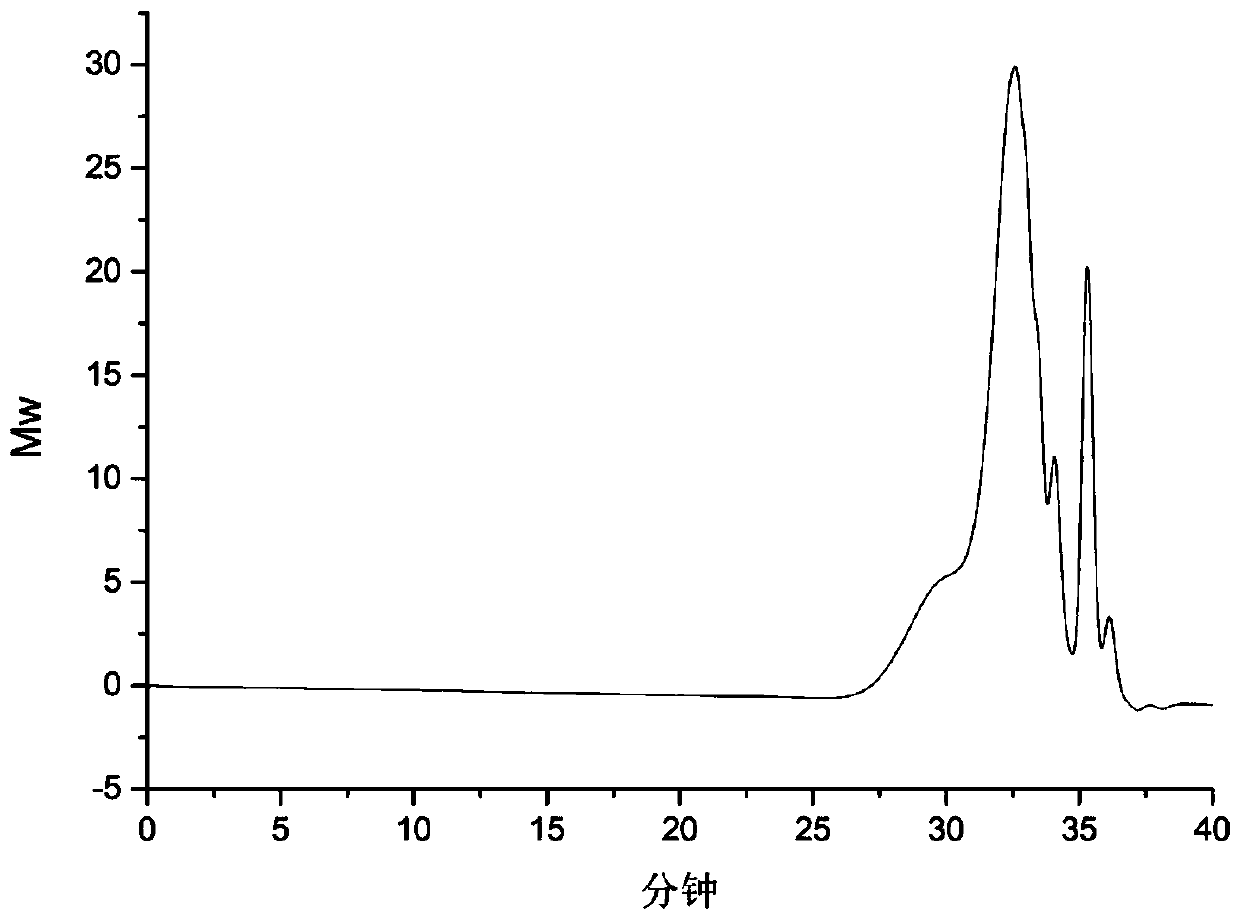

[0014] To achieve the above object, the present invention is achieved through the following technical solutions:

[0015] The olefin-benzoxazine co-oligomer is characterized in that it has the general formula of the following formula I or formula II:

[0016]

[0017]

[0018] Where X=1-100, Y=1-200, Z=0-200

[0019] R 1 =-H,-CH 3 ,-C(CH 3 ) 3 ,-C 15 h 31 -n

[0020] R 2 =-H,-CH3

[0021]

[0022] The present invention also provides a preparation method of the above-mentioned olefin-benzoxazine co-oligomer.

[0023] The preparation method of olefin-benzoxazine co-oligomer comprises steps as follows:

[0024] Aldehyde compounds, phenolic compounds and amine compounds are dissolved in an organic solvent and reacted at 80-120°C for 4-10h, and the obtained benzoxazine monomer and olefin monomer are used at 70-120°C The copolymerization is initiated by a base initiator to obtain an olefin-benzoxazine co-oligomer.

[0025] Preferably according to the present inv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com