Modified pearlescent pigment, preparation method and application thereof, plastic and coating

A pearlescent pigment and modification technology, applied in the field of pigments, can solve problems such as poor pearlescent effect, achieve good pearlescent effect, simple and easy-to-operate preparation method, and easy to control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0055] In addition, the present application also provides a method for preparing the aforementioned modified pearlescent pigment, which may include, for example, the following steps: coating the surface of the pearlescent pigment with a resin matrix to modify the pearlescent pigment.

[0056] In an optional embodiment, coating can be performed by liquid phase deposition.

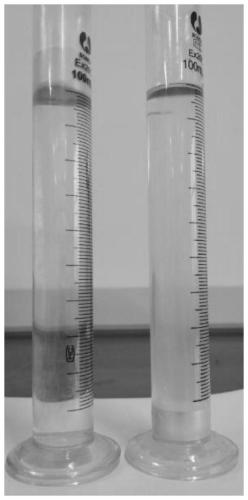

[0057] In an optional embodiment, liquid phase deposition may include, for example: mixing an alkaline solution containing a resin matrix with a slurry of pearlescent pigments, followed by neutralization with an acidic solution.

[0058]In an optional embodiment, 40-80g (such as 40g, 45g, 50g, 55g, 60g, 65g, 70g, 75g or 80g) of pearlescent pigment is dissolved in the solvent in 1000mL of slurry; preferably, 2000mL of The pearlescent pigment of 100g is dissolved in the solvent.

[0059] For reference, the liquid phase deposition can be carried out in the following order: add an alkaline solution containing a...

Embodiment 1

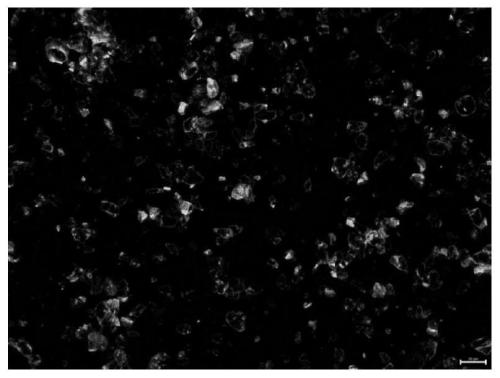

[0081] Weigh 100g of a synthetic mica-based pearlescent pigment with a particle size of 5-45μm and a diameter-to-thickness ratio of ≥60, place it in a 5L round-bottomed flask, add 2000mL of deionized water, put it in a water bath, and stir at a rate of 300rps. Heat up to 30°C, adjust the pH to 6 with 10% hydrochloric acid solution, add 100mL of sodium hydroxide solution (5g of acrylic resin and 10g of sodium hydroxide) containing water-based acrylic resin (molecular weight: 8000) at a rate of 1mL / min, Neutralize with 10% hydrochloric acid solution, keep the pH value at 6 until the reaction is completed, filter, wash, and dry to obtain the modified pearlescent pigment.

Embodiment 2

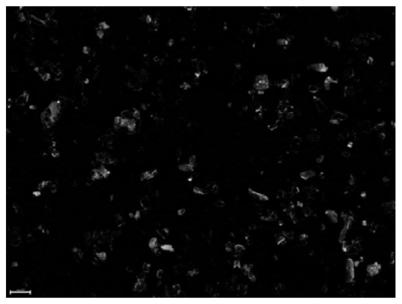

[0083] Weigh 100g of a synthetic mica-based pearlescent pigment with a particle size of 5-45μm and a diameter-to-thickness ratio of ≥60, place it in a 5L round-bottomed flask, add 2000mL of deionized water, put it in a water bath, and stir at a rate of 300rps. Heat up to 80°C, adjust the pH to 5 with 10% hydrochloric acid solution, add 100mL of sodium hydroxide solution (wherein 5g of acrylic resin and 10g of sodium hydroxide) containing water-based acrylic resin (molecular weight is 8000) at a speed of 1mL / min, Neutralize with a hydrochloric acid solution with a mass concentration of 10%, keep the pH value at 5 until the reaction is completed, filter, wash, and dry to obtain the modified pearlescent pigment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com