Preparation method of light-emitting device and light-emitting device

A light-emitting device, electroluminescent layer technology, applied in optics, nonlinear optics, semiconductor/solid-state device manufacturing, etc., can solve the problems of limited improvement range of electrical characteristics, need for additional components, low field-effect mobility, etc. The effect of improving electrical properties, reducing interface scattering, and high mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

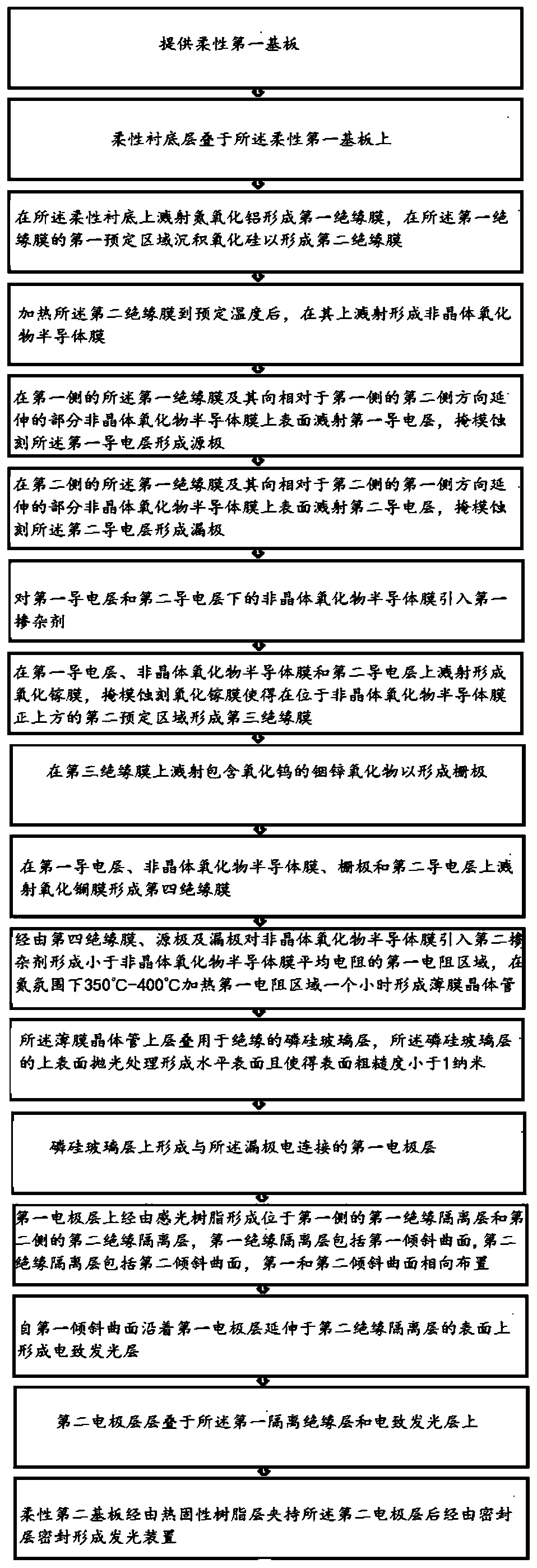

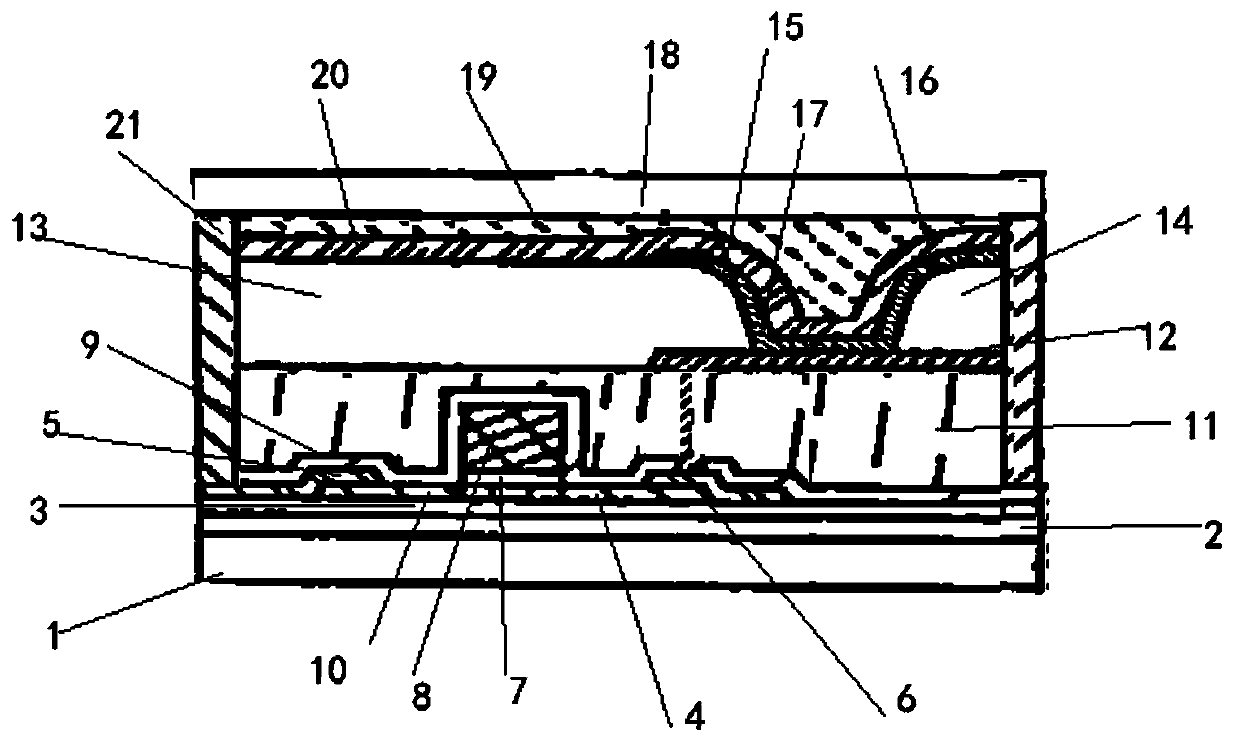

[0042] For better understanding, figure 1 It is a schematic diagram of steps of a method for preparing a light-emitting device according to an embodiment of the present invention, such as figure 1 As shown, a method for preparing a light-emitting device includes the following steps:

[0043] providing a flexible first substrate 1,

[0044] A flexible substrate 2 is stacked on the flexible first substrate 1,

[0045]Aluminum oxynitride is sputtered on the flexible substrate 2 to form a first insulating film 3, silicon oxide is deposited on a first predetermined region of the first insulating film 3 to form a second insulating film, and silicon oxide is formed into a second insulating film. Oxygen can be supplied to the amorphous oxide semiconductor film 4 during filming, and oxygen vacancies in the film can be filled to improve characteristics.

[0046] After heating the second insulating film to a predetermined temperature, an amorphous oxide semiconductor film 4 is formed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

| Average surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com