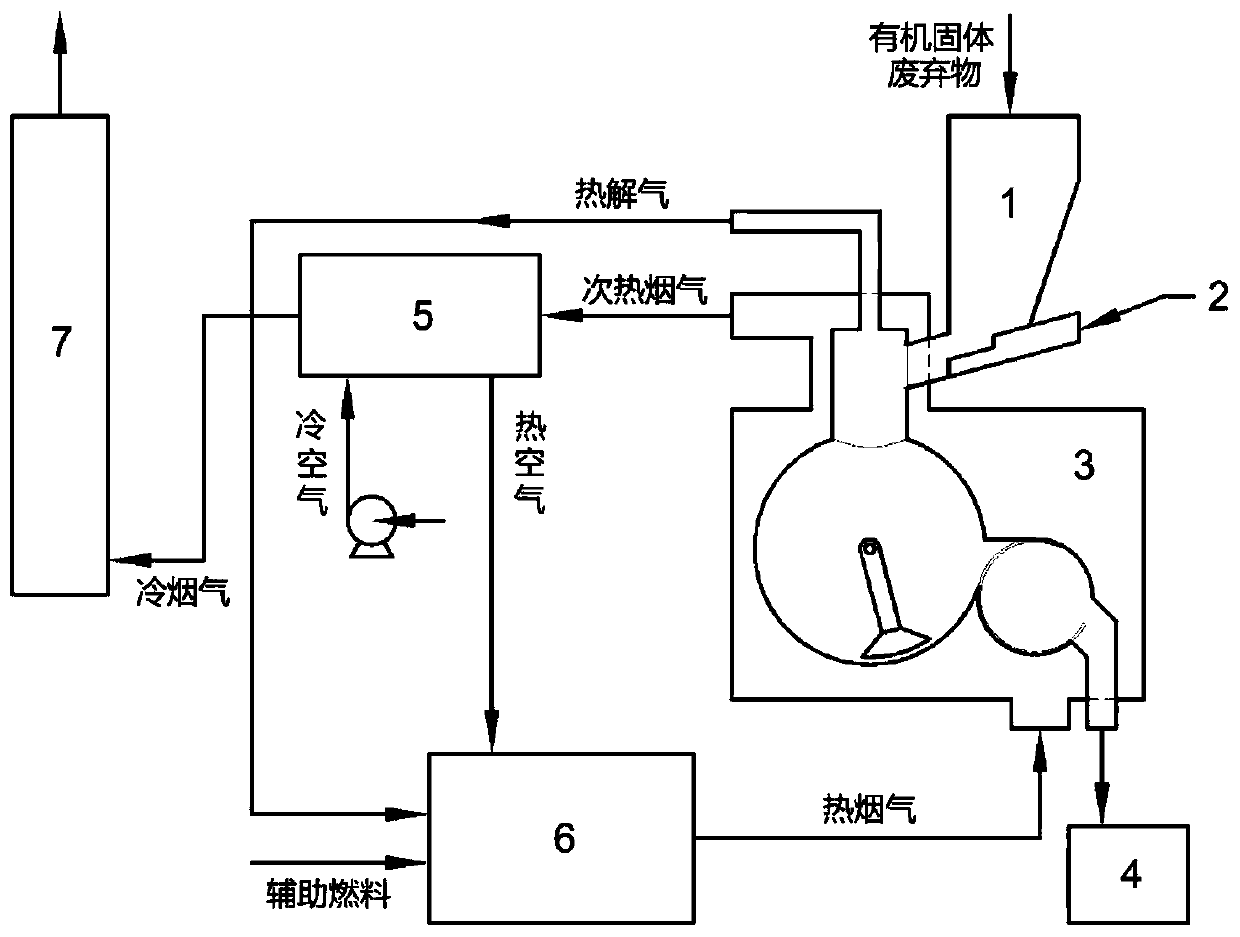

Double-chamber organic solid waste pyrolysis device and pyrolysis method

A technology for organic solids and wastes, applied in unloading devices, indirect heating dry distillation, special form dry distillation, etc., can solve the problems of low energy and space utilization, poor material adaptability, incomplete reaction, etc., and achieve stable pyrolysis process Controllable, prevents easy bridging, and prevents insufficient pyrolysis effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

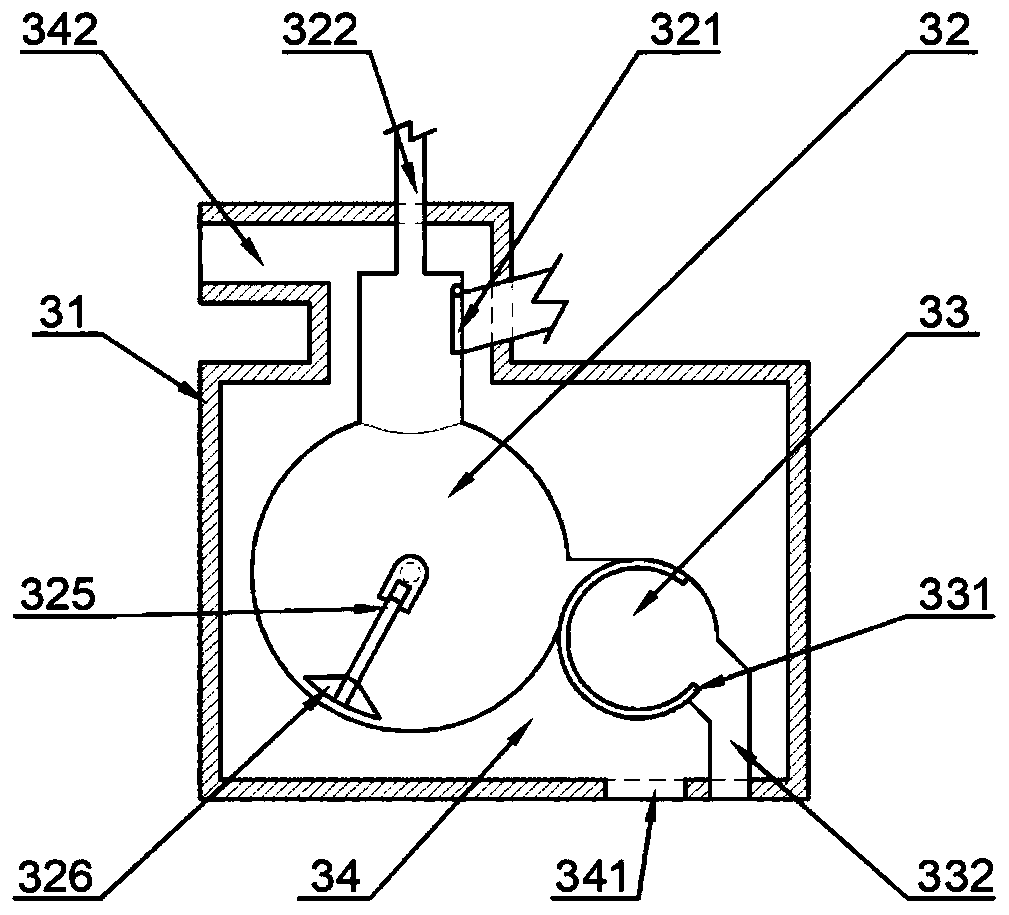

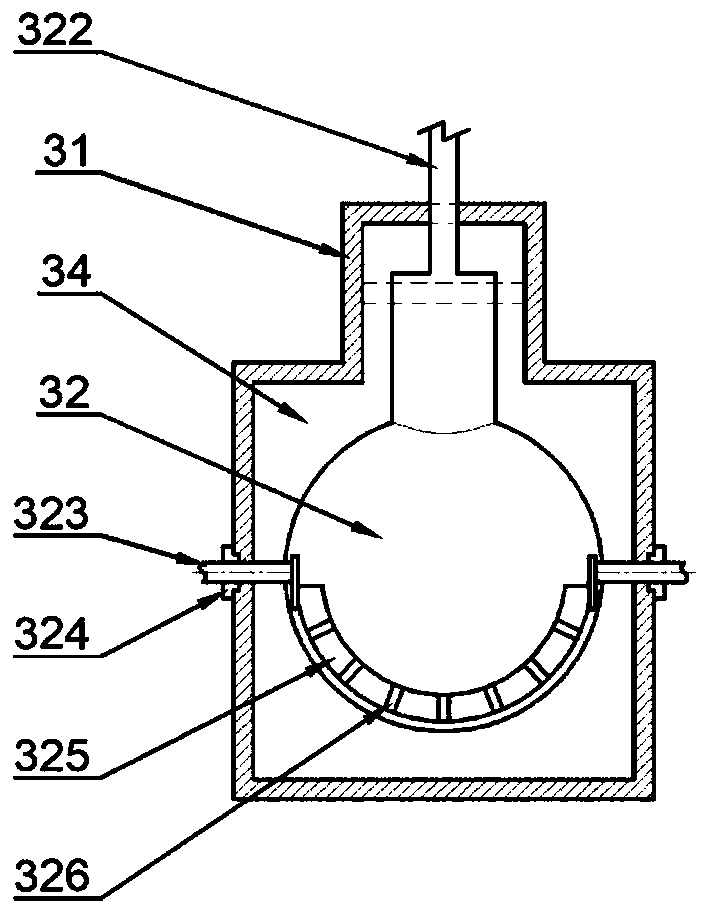

Embodiment 1

[0073] First rotate the rotating inner cylinder 331 to close the entrance of the buffer chamber 33; open the hot air inlet valve and auxiliary fuel inlet valve; adjust the flow of air and auxiliary fuel in the combustion system 6, and use the igniter to ignite to generate high-temperature flue gas , preheat the reaction chamber 32 and the buffer chamber 33; add organic solid waste raw materials into the hopper 1, and after the flue gas with a sufficient temperature is generated, open the feeder of the feeding system 2, and continuously push the domestic waste through the feeding port 321 into the reaction chamber 32, feeding 2t each time; at the same time, turn on the driving motor to make the stirring paddle 325 rotate around the rotating shaft 323, evenly stir the raw materials in the reaction chamber 32, and the speed is maintained at 10r / min; Stop feeding, close feeding system 2; the raw material is evenly heated in the reaction chamber 32 and pyrolyzed, and the pyrolysis t...

Embodiment 2

[0075] First rotate the rotating inner cylinder 331 to close the entrance of the buffer chamber 33; open the hot air inlet valve and auxiliary fuel inlet valve; adjust the flow of air and auxiliary fuel in the combustion system 6, and use the igniter to ignite to generate high-temperature flue gas , preheat the reaction chamber 32 and the buffer chamber 33; add organic solid waste raw materials into the hopper 1, and after the flue gas with sufficient temperature is generated, open the feeder of the feed system 2, and continuously push the sludge from the feed port 321 Into the reaction chamber 32, feed 4t each time; turn on the drive motor at the same time, make the stirring paddle 325 rotate around the rotating shaft 323, evenly stir the raw materials in the reaction chamber 32, and the speed is maintained at 15r / min; after reaching the specified feed amount Stop feeding, close feeding system 2; the raw material is evenly heated and pyrolyzed in the reaction chamber 32, and t...

Embodiment 3

[0077] First rotate the rotating inner cylinder 331 to close the entrance of the buffer chamber 33; open the hot air inlet valve and auxiliary fuel inlet valve; adjust the flow of air and auxiliary fuel in the combustion system 6, and use the igniter to ignite to generate high-temperature flue gas , preheating the reaction chamber 32 and the buffer chamber 33; adding organic solid waste raw materials into the hopper 1; into the reaction chamber 32, feeding 3t each time; at the same time, turn on the driving motor to make the stirring paddle 325 rotate around the rotating shaft 323, evenly stir the raw materials in the reaction chamber 32, and the rotating speed is maintained at 10r / min; Stop feeding, close feeding system 2; the raw material is evenly heated in the reaction chamber 32 and pyrolyzed, and the pyrolysis temperature is 430°C; the raw material is continuously pyrolyzed to generate pyrolysis gas, which passes through the pyrolysis gas pipe above the reaction chamber 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com