A method for increasing the manganese element of molten steel at the end point of converter

A converter end point and converter technology, which is applied in the field of iron and steel metallurgy and steelmaking, can solve the problems of lower smelting costs and greater influence of molten steel quality improvement, increased phosphorus return to molten steel at the end of the converter, and reduced alloy recovery rate in the tapping process. The dephosphorization efficiency in the early stage is beneficial to the maintenance of the furnace body and the effect of reducing the maintenance cost of the furnace body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1100

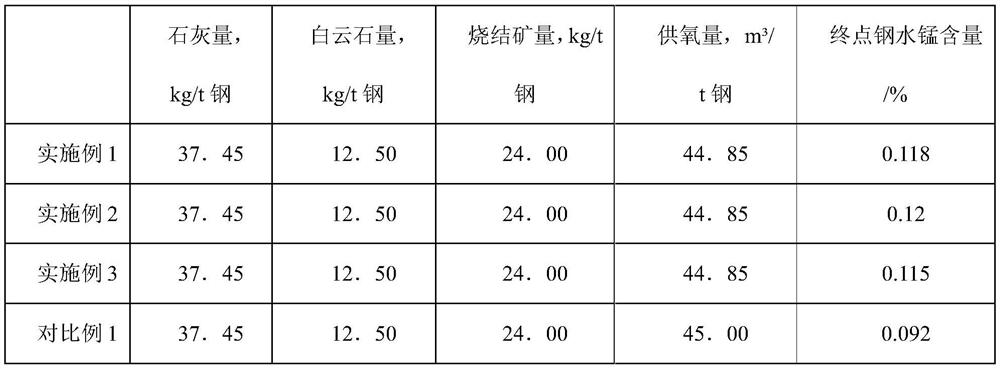

[0030] Example 1 End point control of 100-ton oxygen top-bottom combined blowing converter

[0031] A method for increasing the manganese element of molten steel at the end point of a converter, the method comprising the following steps:

[0032] 1) The silicon content of molten iron entering the converter is 0.50%, the manganese content is 0.20%, and the oxygen supply intensity is 3.0m 3 / t.min, before smelting, the end time of silicon and manganese oxidation period is calculated according to the content of silicon and manganese in molten iron, which is 3 minutes and 6 seconds; and the amount of lime added is calculated according to the basicity of slag 2.8 and the effective calcium oxide of lime at 80%. =2.14*2.8*0.50%*100 / 80%*1000=3745kg, the amount of sinter added is calculated as 24kg / t steel according to the heat balance.

[0033] 2) Add 2675kg of lime to the converter, add 1000kg to the first batch of dolomite, and the oxygen flow rate is 18000m 3 / h, gun position 150...

Embodiment 2250

[0038] Example 2 End point control of a 250-ton oxygen top-bottom double-blown converter

[0039] A method for increasing the manganese element of molten steel at the end point of a converter, the method comprising the following steps:

[0040] 1) The silicon content of the molten iron into the converter is 0.50%, the manganese content is 0.20%, and the oxygen supply intensity is 2.5m 3 / t.min, the end time of silicon and manganese oxidation period calculated according to the silicon and manganese content of molten iron before smelting is 3 minutes and 44 seconds; and according to the slag alkalinity of 2.8 and lime effective calcium oxide as 80%, the lime addition amount is calculated, Calculate the amount of sinter added according to the heat balance.

[0041] 2) Add 6687kg of lime to the converter, add 2500kg to the first batch of dolomite, and add oxygen flow rate of 37500m 3 / h, gun position 1800mm; smelting to 2 minutes and 47 seconds to add lime 1337kg, oxygen flow rat...

Embodiment 3

[0046] Example 3 End point control of a 100-ton oxygen top-bottom double-blown converter

[0047] A method for increasing the manganese element of molten steel at the end point of a converter, the method comprising the following steps:

[0048] 1) The silicon content of molten iron entering the converter is 0.50%, the manganese content is 0.20%, and the oxygen supply intensity is 3.0m 3 / t.min, before smelting, according to the silicon and manganese content of molten iron, the end time of the silicon and manganese oxidation period is calculated as 3 minutes and 6 seconds; and according to the slag alkalinity of 2.8, the effective calcium oxide of lime is 80%, and the lime addition amount is calculated. Calculate the amount of sinter added according to the heat balance.

[0049] 2) Add 2675kg of lime to the converter, add 1000kg to the first batch of dolomite, and the oxygen flow rate is 18000m 3 / h, gun position 1500mm; smelting to 2 minutes and 19 seconds to add lime 535kg,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com