Preparation method and application of oxygen-doped molybdenum disulfide material with defects

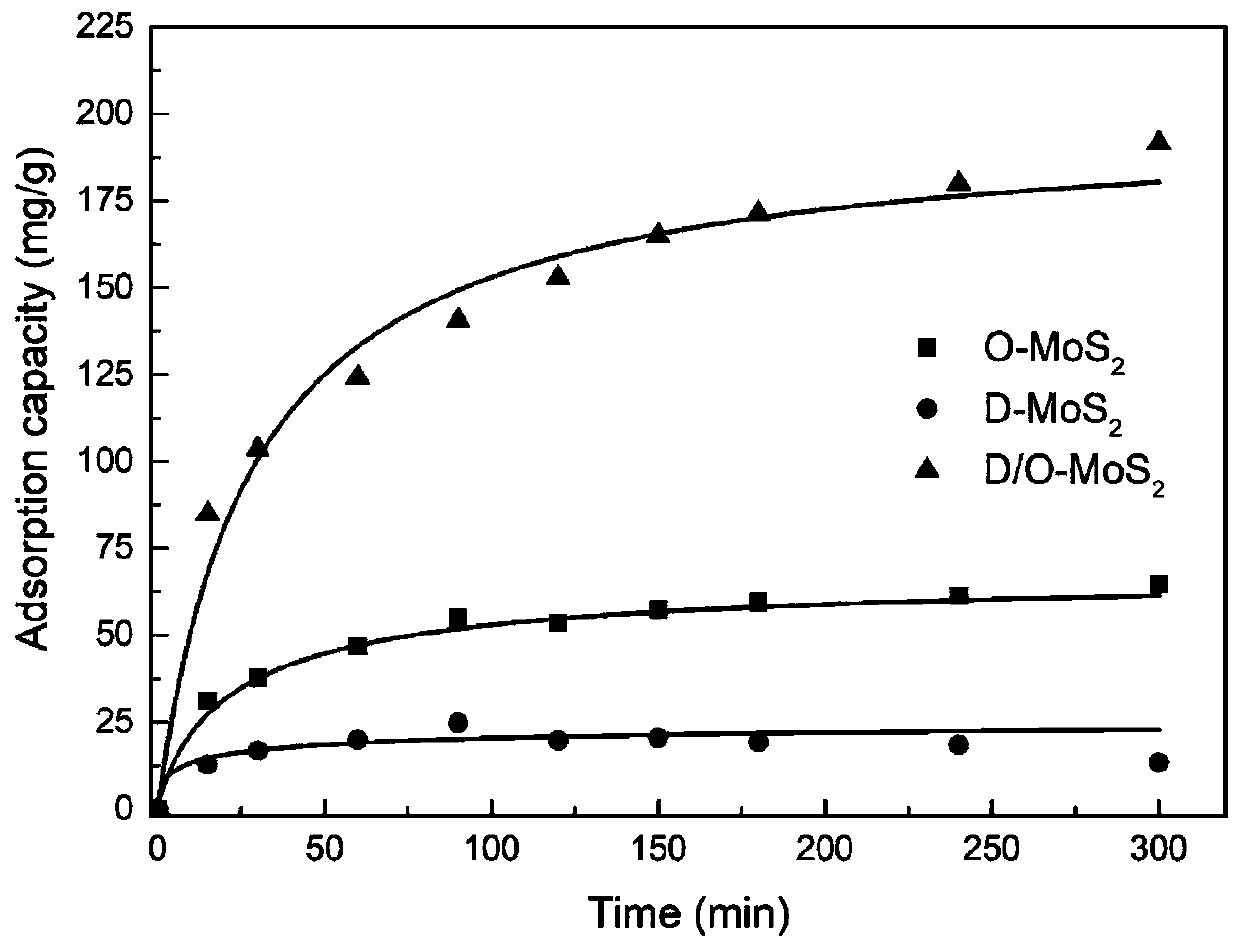

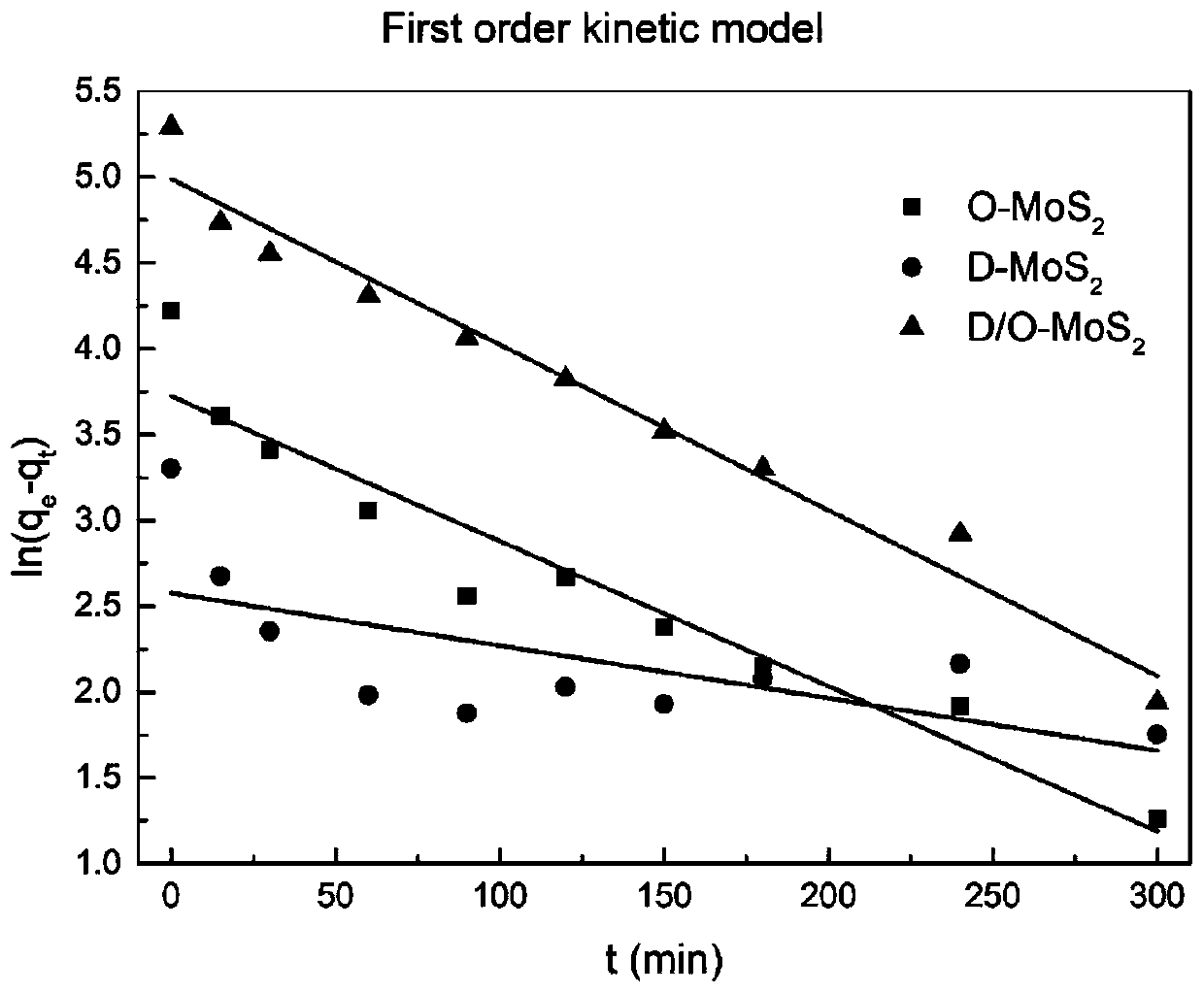

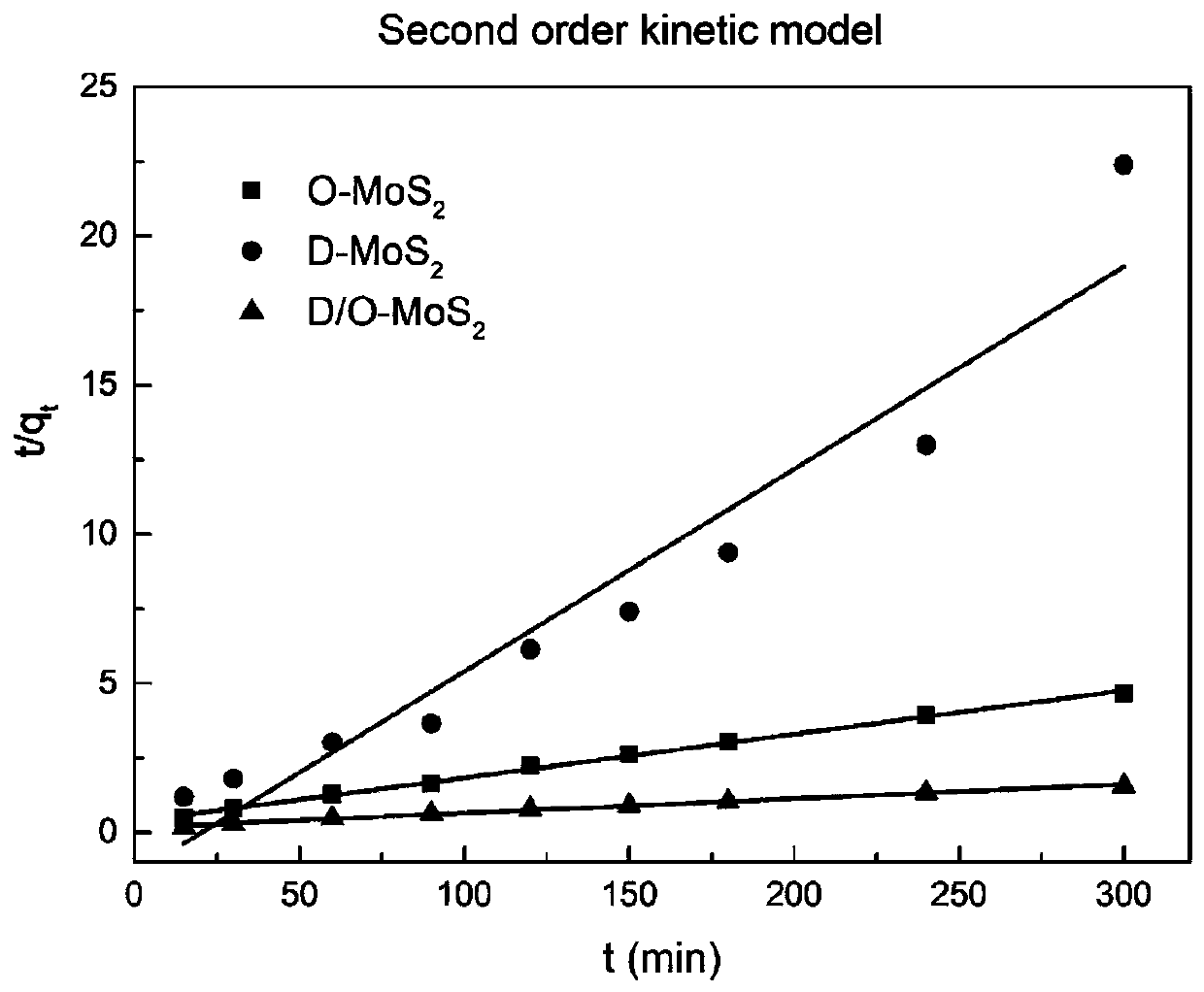

A molybdenum disulfide and oxygen doping technology, applied in molybdenum sulfide, chemical instruments and methods, and other chemical processes, can solve the problems of inhibiting the growth of aquatic organisms and difficult to degrade, and achieve fast adsorption rate, increased adsorption capacity, and practical The effect of performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A method for preparing an oxygen-doped molybdenum disulfide material 1 with defects, comprising the following steps:

[0033] 1) Weigh 2.48g of ammonium molybdate tetrahydrate, 4.56g of thiourea and 72mL of deionized water for subsequent use;

[0034] 2) dissolving ammonium molybdate tetrahydrate and thiourea in water to obtain a mixture;

[0035] 3) Add the mixture into the reaction kettle, and conduct a hydrothermal reaction at a temperature of 220°C for 24 hours; a black precipitate is obtained;

[0036] 4) The black precipitate was washed with deionized water, dried in vacuum at a temperature of 60° C., and finally calcined in air at a temperature of 330° C. for 2 hours; an oxygen-doped molybdenum disulfide material 1 with defects was obtained.

Embodiment 2

[0038] A method for preparing an oxygen-doped molybdenum disulfide material 2 with defects, comprising the following steps:

[0039] 1) Weigh 2.48g of ammonium molybdate tetrahydrate, 4.56g of thiourea and 72mL of deionized water for subsequent use;

[0040] 2) dissolving ammonium molybdate tetrahydrate and thiourea in water to obtain a mixture;

[0041] 3) Add the mixture into the reactor, and conduct a hydrothermal reaction at a temperature of 220° C. for 18 hours; a black precipitate is obtained;

[0042] 4) The black precipitate was washed with deionized water, dried in vacuum at a temperature of 60° C., and finally calcined in air at a temperature of 330° C. for 2 hours; an oxygen-doped molybdenum disulfide material 2 with defects was obtained.

Embodiment 3

[0044] A method for preparing an oxygen-doped molybdenum disulfide material 3 with defects, comprising the following steps:

[0045] 1) Weigh 2.48g of ammonium molybdate tetrahydrate, 4.56g of thiourea and 72mL of deionized water for subsequent use;

[0046] 2) dissolving ammonium molybdate tetrahydrate and thiourea in water to obtain a mixture;

[0047] 3) Add the mixture into the reaction kettle, and conduct a hydrothermal reaction at a temperature of 220° C. for 12 hours; a black precipitate is obtained;

[0048] 4) The black precipitate was washed with deionized water, dried in vacuum at a temperature of 60° C., and finally calcined for 2 hours at a temperature of 330° C. in air; an oxygen-doped molybdenum disulfide material 3 with defects was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com