Numerically controlled equipment with double spray head attle discharging mechanism

A technology of numerical control equipment and double nozzles, which is applied in the direction of metal processing equipment, manufacturing tools, metal processing machinery parts, etc., can solve the problems of slow discharge efficiency, iron filings are easy to damage the inside of the equipment, heavy weight and inconvenient rapid discharge, etc., to increase safety resistance, reducing the effect of spatter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

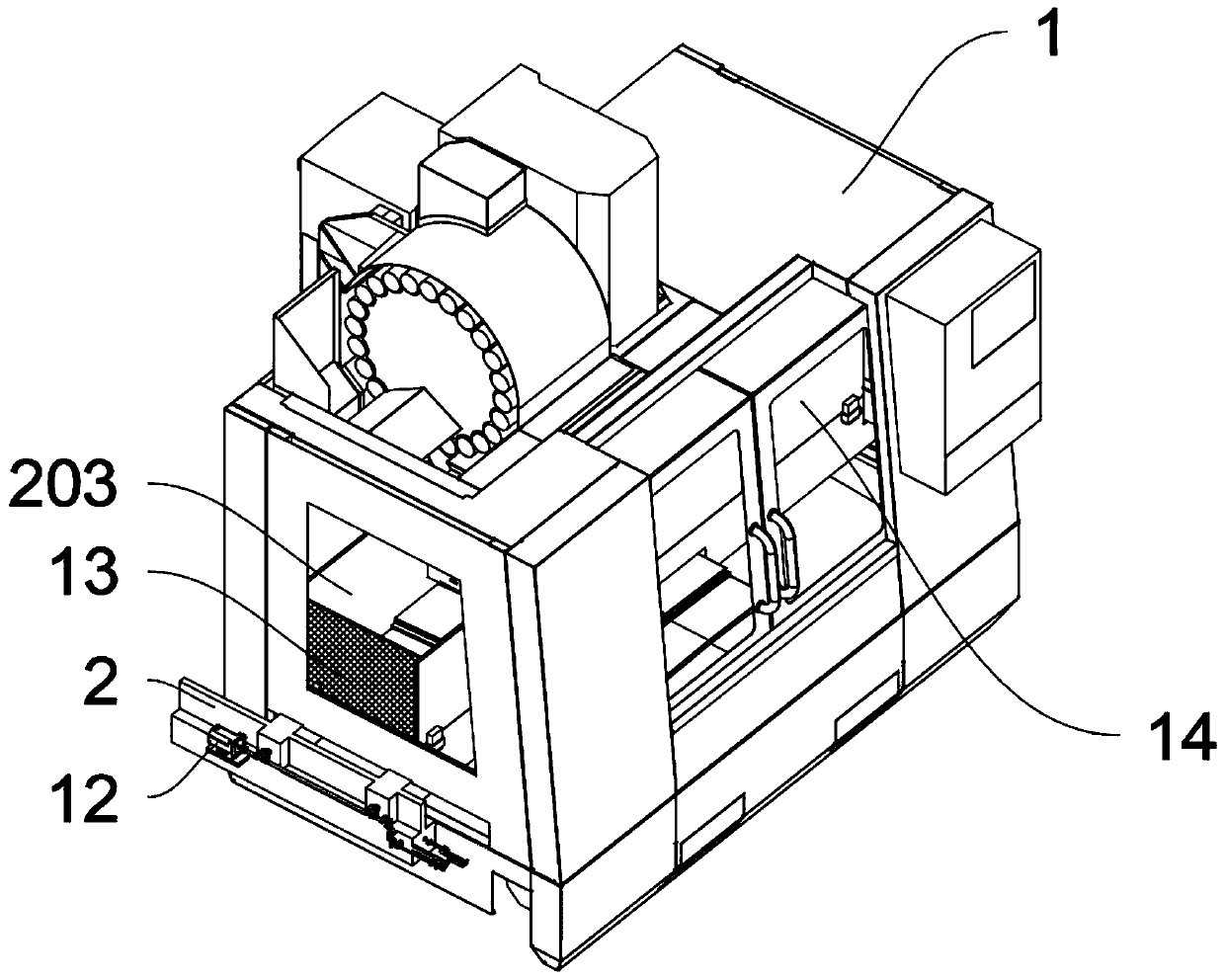

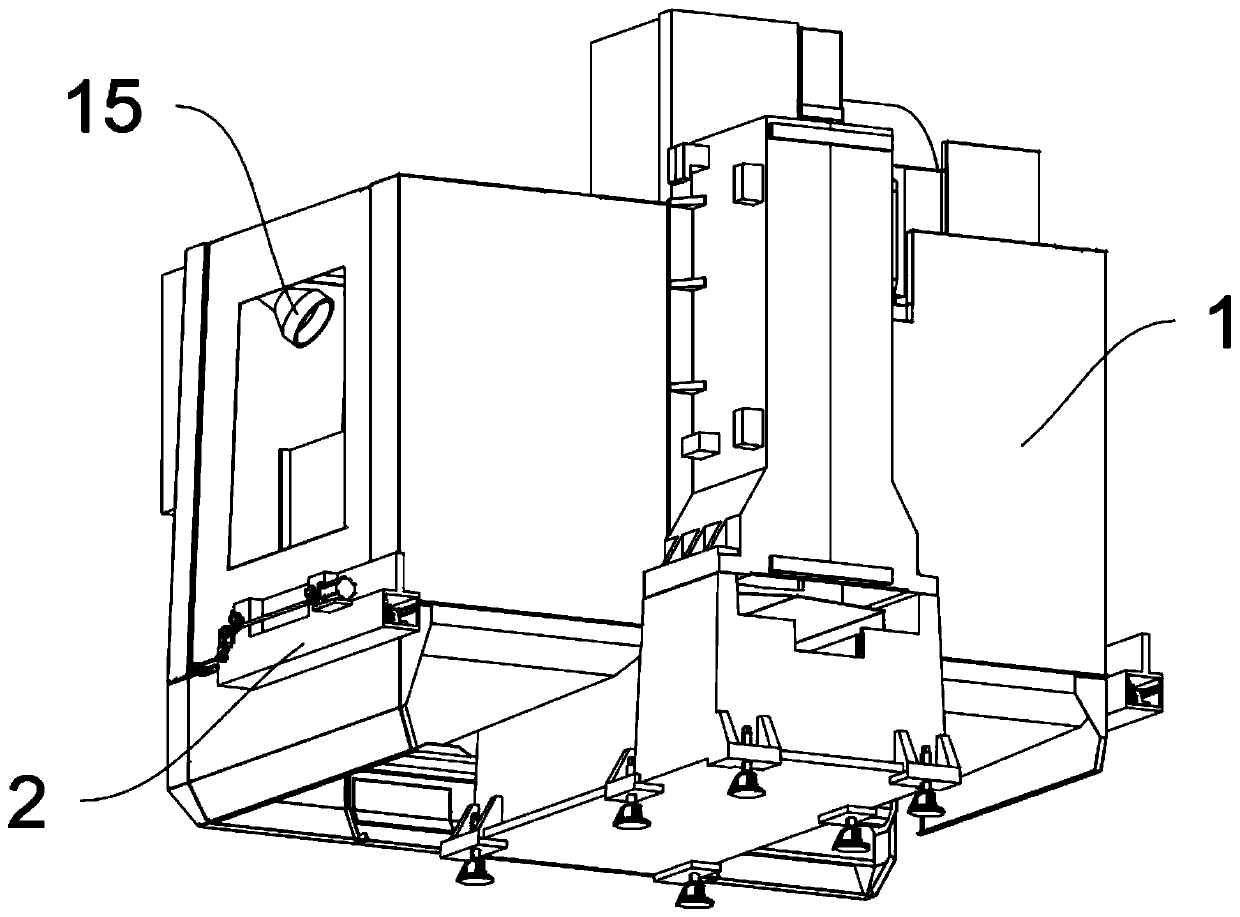

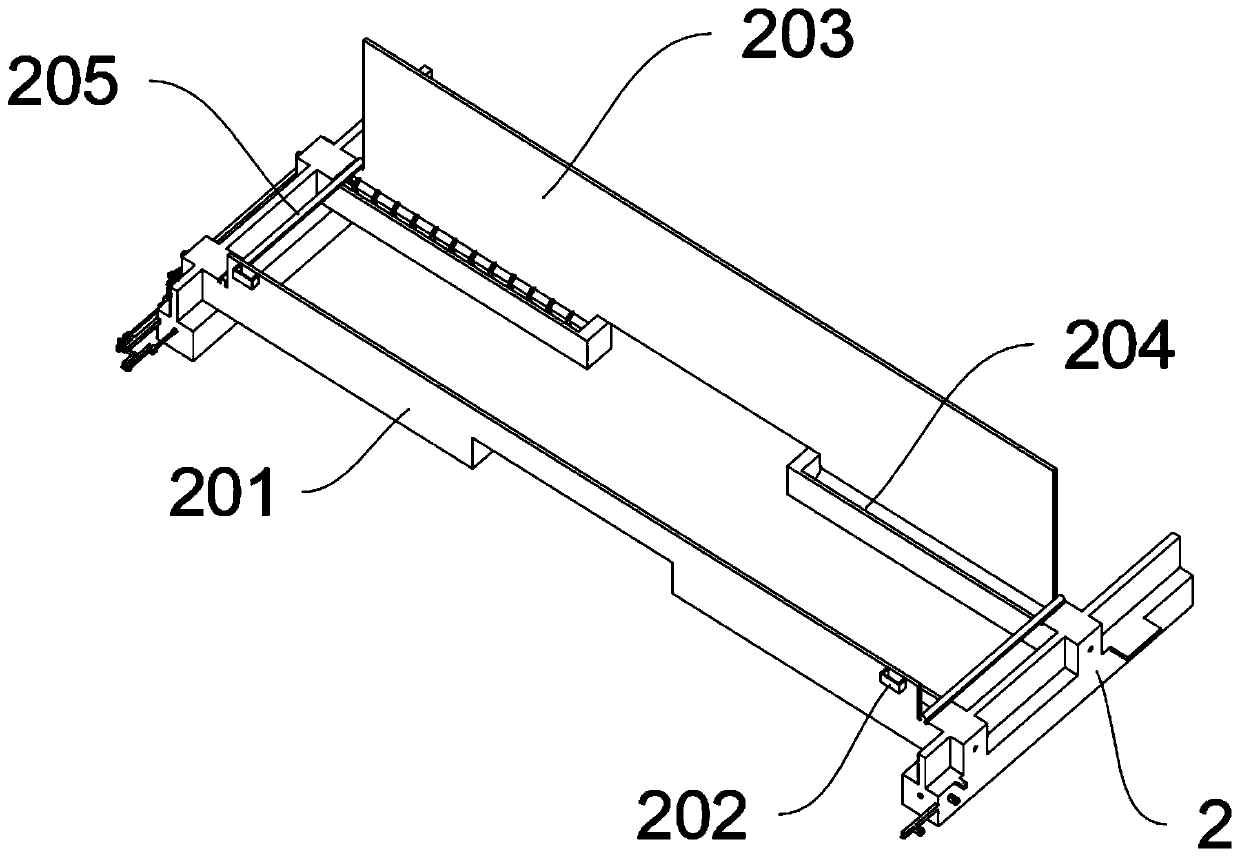

[0032] see Figure 1 to Figure 8, an embodiment provided by the present invention: a kind of numerical control equipment equipped with a waste discharge mechanism with double nozzles, including a machine tool 1; A discharge channel 2 is slidingly arranged in the side square gap; wherein, the discharge channel 2 also includes a front baffle 201, an insert frame 202, a rear baffle 203, and a discharge chute 204; the middle of the front side of the discharge channel 2 is integrated A front baffle 201 is arranged in the form of a front baffle 201, and two sets of insert frames 202 are integrally arranged on the top of the outer ends on both sides of the front baffle 201;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com