Composite zirconium oxide material and preparation method thereof

A zirconia and oxide technology, which is applied in the field of composite zirconia materials and its preparation, can solve the problems of dielectric constant, dielectric loss and dielectric properties that do not meet the application requirements of millimeter wave frequency band.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

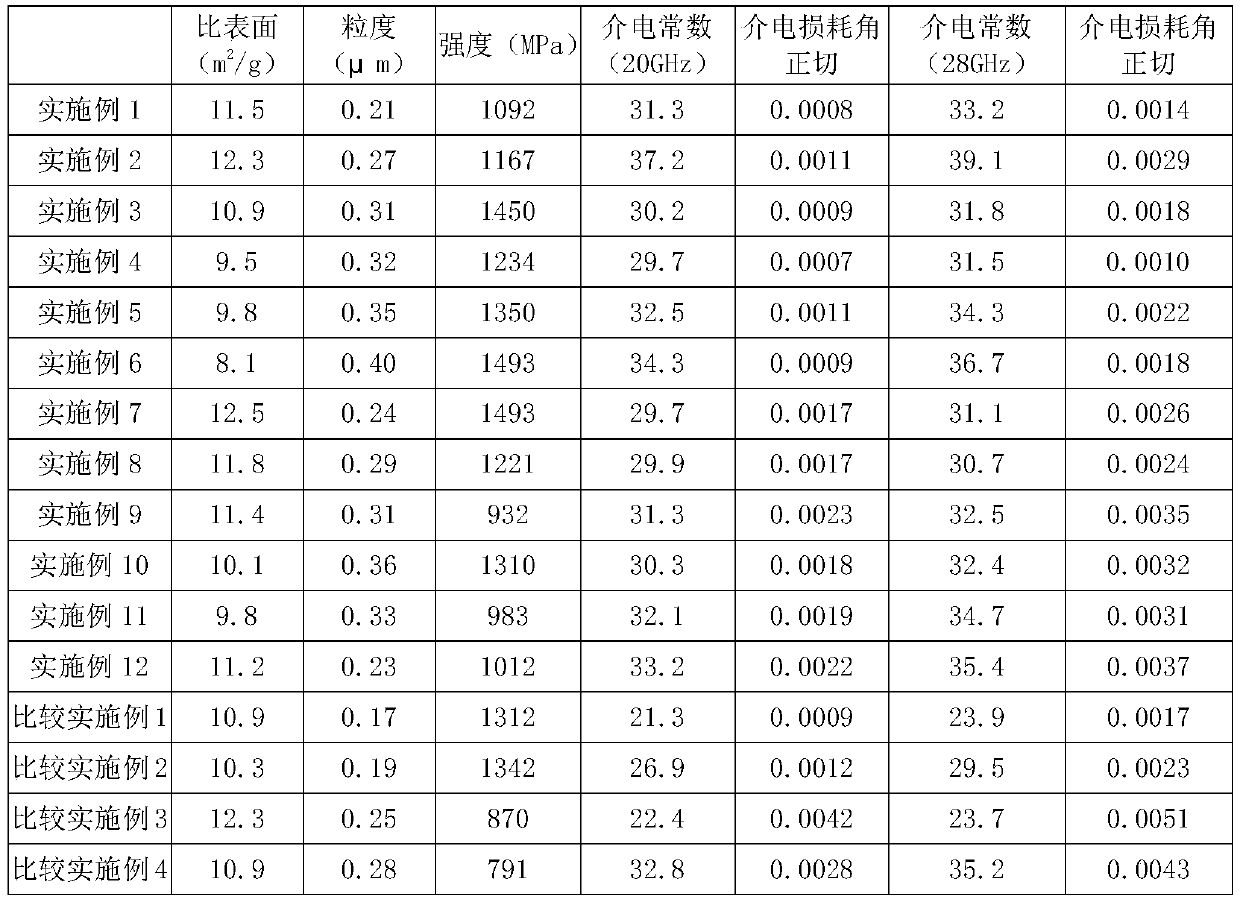

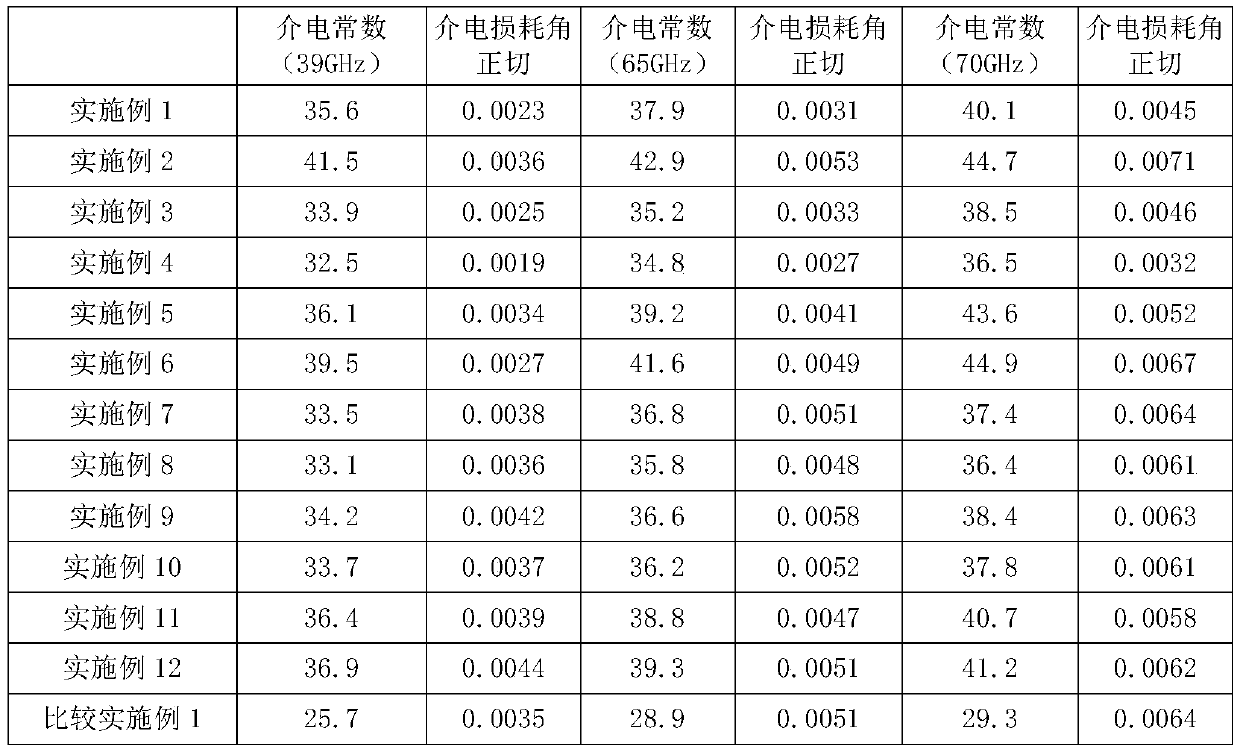

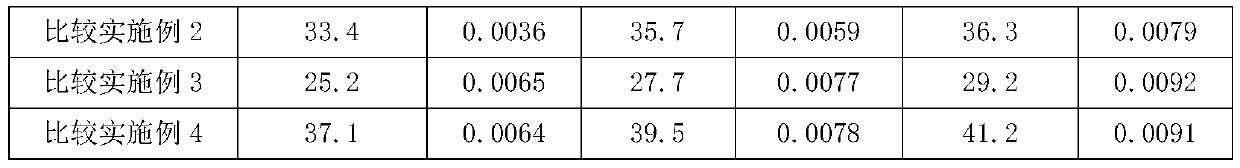

Examples

preparation example Construction

[0024] According to another aspect of the present invention, there is also provided a method for preparing the above-mentioned composite zirconia material, the preparation method comprising the following steps: according to the elemental composition of the composite zirconia material to be prepared, the zirconium salt and the salt of the doping element Mix to form a solid mixed salt; heat the solid mixed salt in a medium-temperature furnace to 400-500°C for low-temperature calcination to obtain a precursor; disperse the precursor in a planetary mill to obtain a dispersed precursor; disperse the precursor at 1000- High-temperature calcination at 1200°C to obtain a composite zirconia material.

[0025]In the above method provided by the present invention, specific doping elements are selected to dope zirconia. The uniformity of the finished product can be improved through solid powder mixing, low-temperature calcination and post-sand grinding dispersion, and then high-temperatur...

Embodiment 1

[0033] Weigh 200g of zirconium oxychloride and 6.22g of yttrium chloride respectively, put them into a crucible and mix them evenly, then add 0.99g of barium hydroxide, put them into a dry mixer, and disperse at a speed of 30r / s for 5h.

[0034] After mixing evenly, put it into a medium-temperature furnace, first keep it at 170°C for 2h, and then raise the temperature to 400°C within 1.5h and keep it at 2h to obtain the precursor. Disperse the precursor evenly in the planetary mill at a rotation speed of 250r / s for 30min, and then dry it.

[0035] After dispersion, the powder was put into a high-temperature furnace with exhaust gas, and calcined at 1000°C for 4 hours to obtain the final sample.

[0036] In the final sample, based on oxides, the doping amount of Y element in the composite zirconia material is 4.46%, and the doping amount of Ba element is 0.61%.

Embodiment 2

[0038] Compared with Example 1, the difference is that the addition of yttrium chloride is 1.63g, the addition of barium hydroxide is 2.43g, and other parameters are the same as in Example 1.

[0039] In the final sample, based on oxides, the doping amount of Y element in the composite zirconia material is 1.2%, and the doping amount of Ba element is 1.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com