A kind of self-thickening surfactant and preparation method thereof

A surfactant, self-thickening technology, used in the preparation of carboxylic acid esters, the preparation of carboxylic acid halides, chemical instruments and methods, etc., can solve difficult biodegradation, increased cost of viscoelastic fluids, high toxicity and irritation and other problems, to achieve the effect of strong self-assembly ability, convenient on-site preparation and viscosity reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

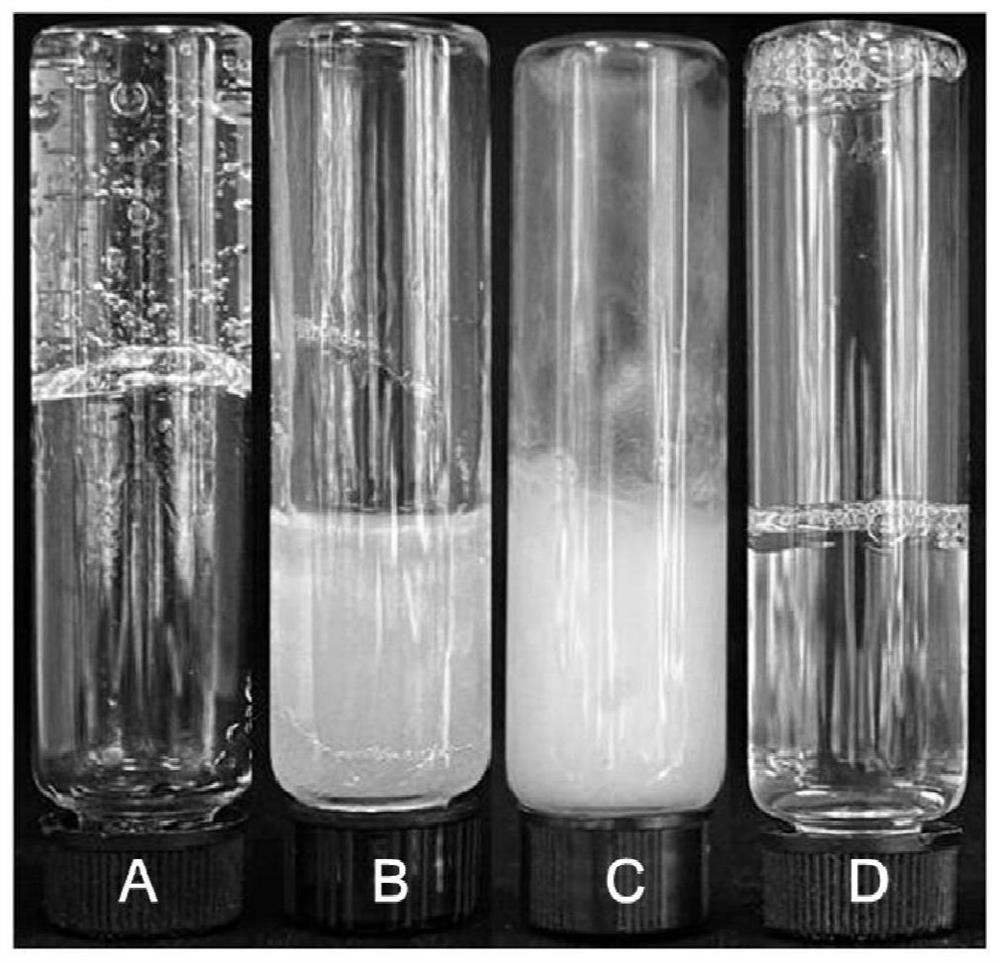

Embodiment 1

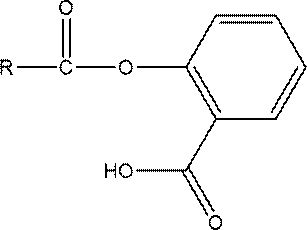

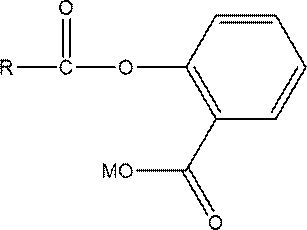

[0038] 3 mmol erucic acid chloride and 3 mmol salicylic acid were solubilized in 50 g nanoemulsion (13.5 g 1-butyl-3-methylimidazolium hexafluorophosphate, 12.5 g DMSO and 24 g water), respectively, Then, the nanoemulsion containing erucic acid chloride was added dropwise into the nanoemulsion containing salicylic acid at 30° C., and stirred for 1 hour.

[0039] Aqueous sodium hydroxide (3 mmol) was added dropwise and stirring was continued for 0.5 hours. The temperature was lowered to 20° C., the water layer was collected, and the solvent was spin-dried to obtain the sodium salt of salicylate erucate, and the yield was 97% as measured by high performance liquid chromatography.

Embodiment 2

[0041] Solubilize 3 mmol of stearic acid chloride and 3 mmol of salicylic acid respectively in 50 g of nanoemulsion (15 g of 1-butyl-3-methylimidazolium hexafluorophosphate, 15 g of DMSO and 20 g of water) , and then the nanoemulsion containing stearic acid chloride was added dropwise to the nanoemulsion containing salicylic acid at 30° C., and stirred for 1.5 hours.

[0042] Aqueous potassium hydroxide (3 mmol) was added dropwise and stirring was continued for 1 hour. The temperature was lowered to 20° C., the water layer was collected, and the solvent was spin-dried to obtain the potassium salt of salicylate stearate, and the yield was 95% as measured by high performance liquid chromatography.

Embodiment 3

[0044] Solubilize 3 mmol of behenic acid chloride and 3 mmol of salicylic acid, respectively, in 50 g of nanoemulsion (17 g of 1-butyl-3-methylimidazolium hexafluorophosphate, 14 g of DMSO, and 19 g of water) , and then drop the nanoemulsion containing behenic acid chloride into the nanoemulsion containing salicylic acid at 30° C., and stir for 1 hour.

[0045] An aqueous solution of choline hydroxide (3 mmol) was added dropwise and stirring was continued for 0.5 hours. The temperature was lowered to 20° C., the water layer was collected, and the solvent was spin-dried to obtain the choline behenate salicylate, and the yield was 99% as measured by high performance liquid chromatography.

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com