Polyimide single-ion polymer, preparation method thereof and solid polymer electrolyte membrane

A technology based on ionic polymers and polyimides, applied in the field of polymers and lithium-ion batteries, can solve the problem of difficult balance between thermal stability and electrochemical stability of polymer electrolyte membranes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

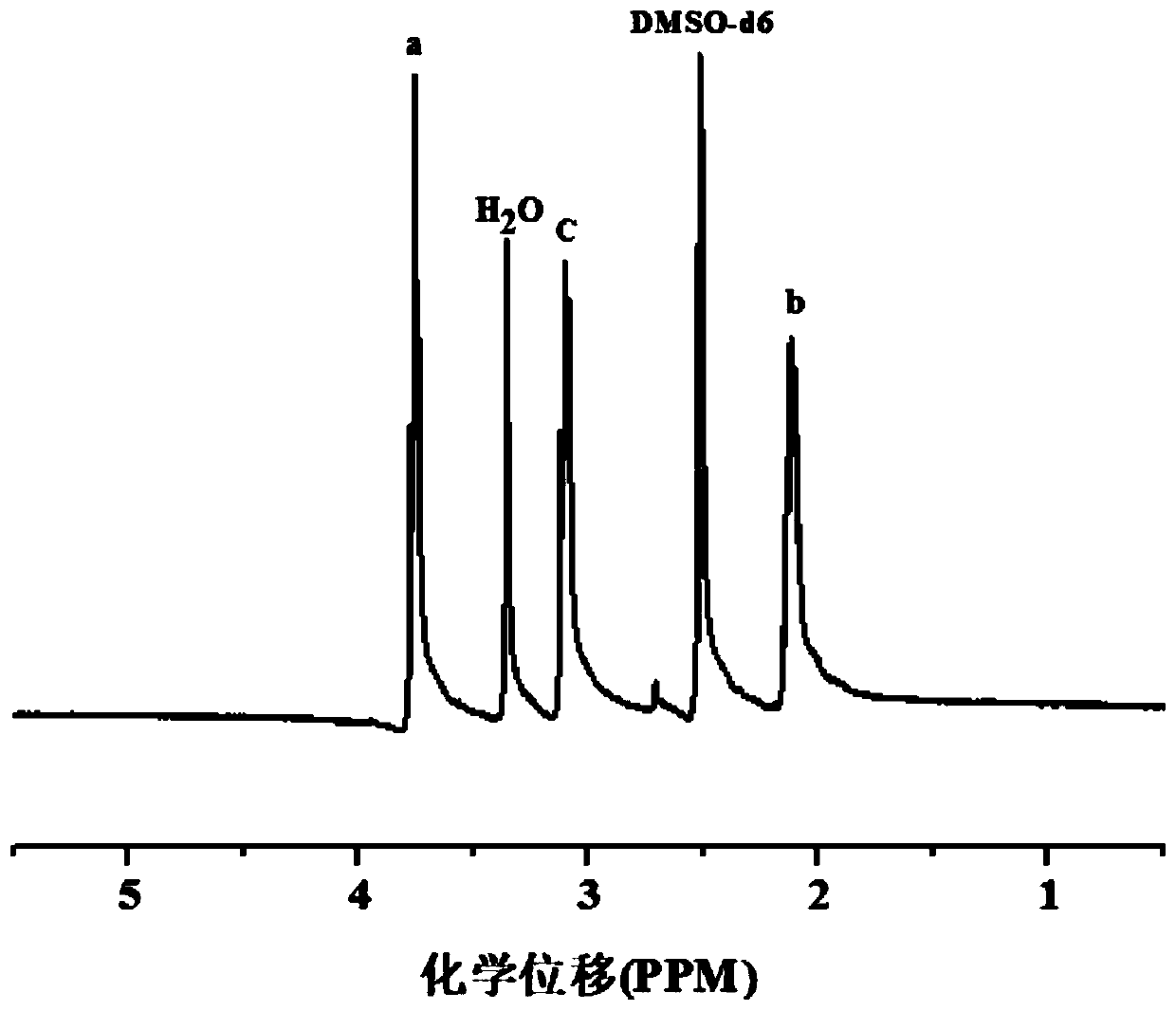

[0048] a. 3-Chloropropanesulfonyl lithium (trifluoromethanesulfonyl)imide Preparation of:

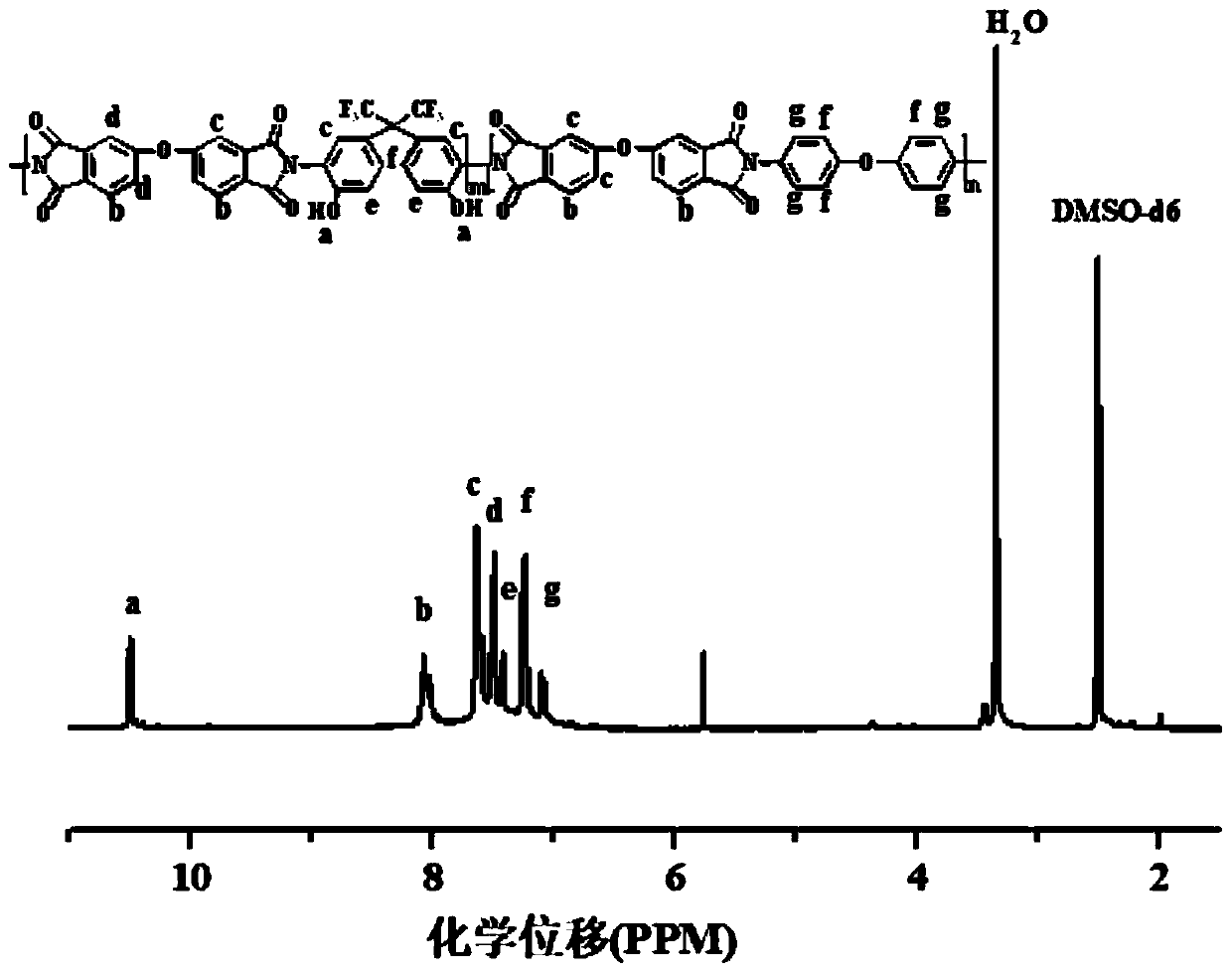

[0049] Add 10mmol (1.4909g) of trifluoromethanesulfonamide and 20mmol (0.4786g) of LiOH to 10ml of anhydrous acetonitrile, fill with nitrogen to maintain an inert atmosphere, and add 10mmol (1.7705g) of 3- Chloropropanesulfonyl chloride was reacted at room temperature for 20 hours, acetonitrile was removed by rotary evaporation, and the obtained 3-chloropropanesulfonyl lithium (trifluoromethanesulfonyl)imide solid was recrystallized in dichloromethane, and 1.8125 g of white solid was obtained by filtration. That 1 HMR spectrum such as figure 1 shown.

[0050] b. Synthesis of Polyimides Containing Hydroxyl :

[0051] 2,2'-bis(3-amino-4-hydroxyphenyl)hexafluoropropane (AHHFP), 4,4'-oxydiphthalic anhydride (ODPA), and 4,4'-diaminobis Add 1.83g, 3.10g, and 1.00g of phenyl ether (ODA) respectively (molar ratio is 1:2:1), add 35mL of m-cresol, pass nitrogen, add a drying tube, stir ev...

Embodiment 2

[0060] (1) Add 20mmol (2.9818g) of trifluoromethanesulfonamide and 40mmol (0.9572g) of LiOH to 20ml of anhydrous acetonitrile, fill with nitrogen to maintain an inert atmosphere, and add 20mmol (3.541g) in an ice-water bath 3-chloropropanesulfonyl chloride, react at room temperature for 20h, remove acetonitrile by rotary evaporation, recrystallize the solid 3-chloropropanesulfonyl lithium (trifluoromethanesulfonyl)imide in dichloromethane, and filter to obtain 3.628g white solid.

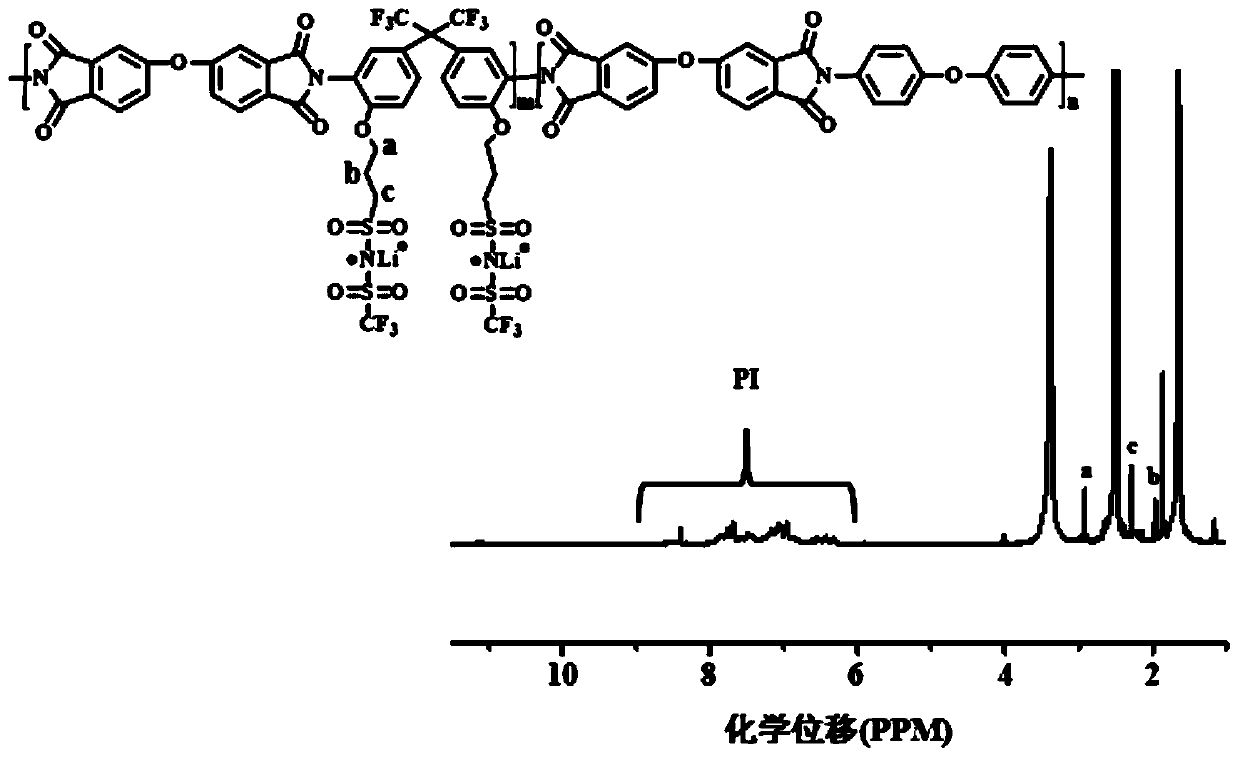

[0061] (2) 2,2'-bis(3-amino-4-hydroxyphenyl)hexafluoropropane (AHHFP), 4,4'-oxydiphthalic anhydride (ODPA), and 4,4'- Add 2.56g, 3.10g, and 0.60g of diaminodiphenyl ether (ODA) respectively (the molar ratio is 7:10:3), add 25mL of m-cresol, pass nitrogen, add a drying tube, stir evenly, and heat up to 80 Heat and stir at ℃ for 4 hours, then add 2.5 mL of isoquinoline, stir evenly, heat to 180 ℃, react for 18 hours, pour the reaction liquid into ethanol, form fibers, wash with water and ethanol alte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com