PA/PE blend alloy with low water absorption and high dimensional stability and preparation method thereof

A technology with dimensional stability and low water absorption, applied in the field of polymer materials, can solve the problems of PA/PE alloy water absorption and dimensional stability improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

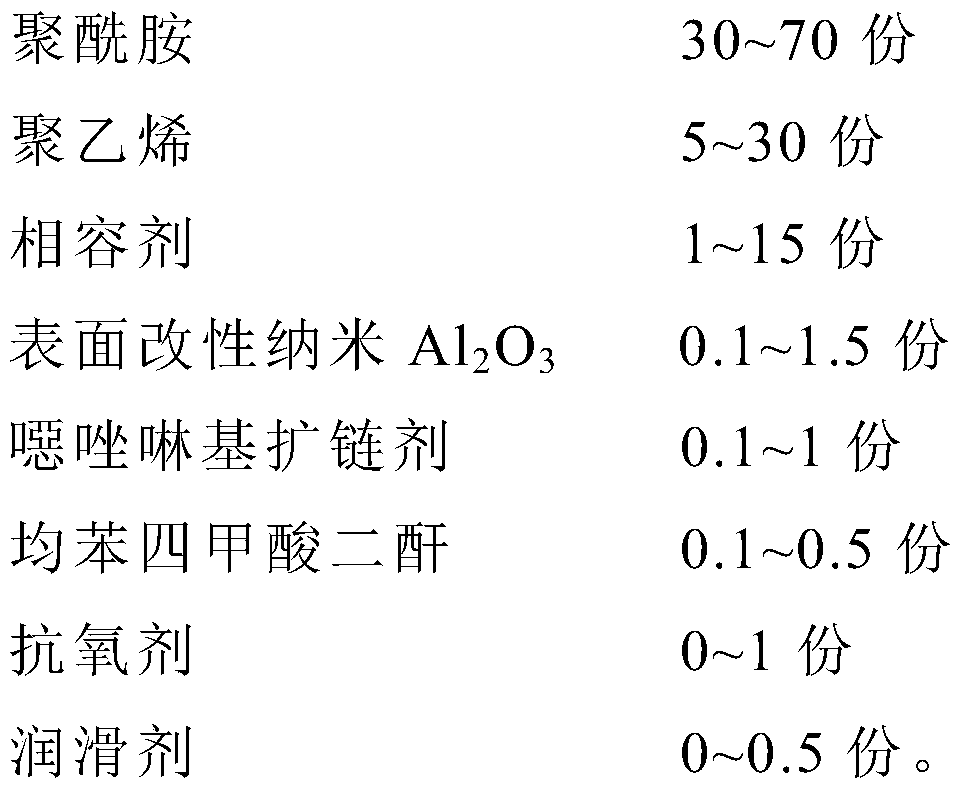

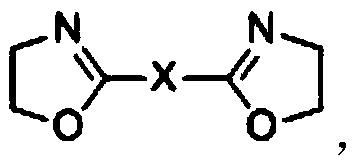

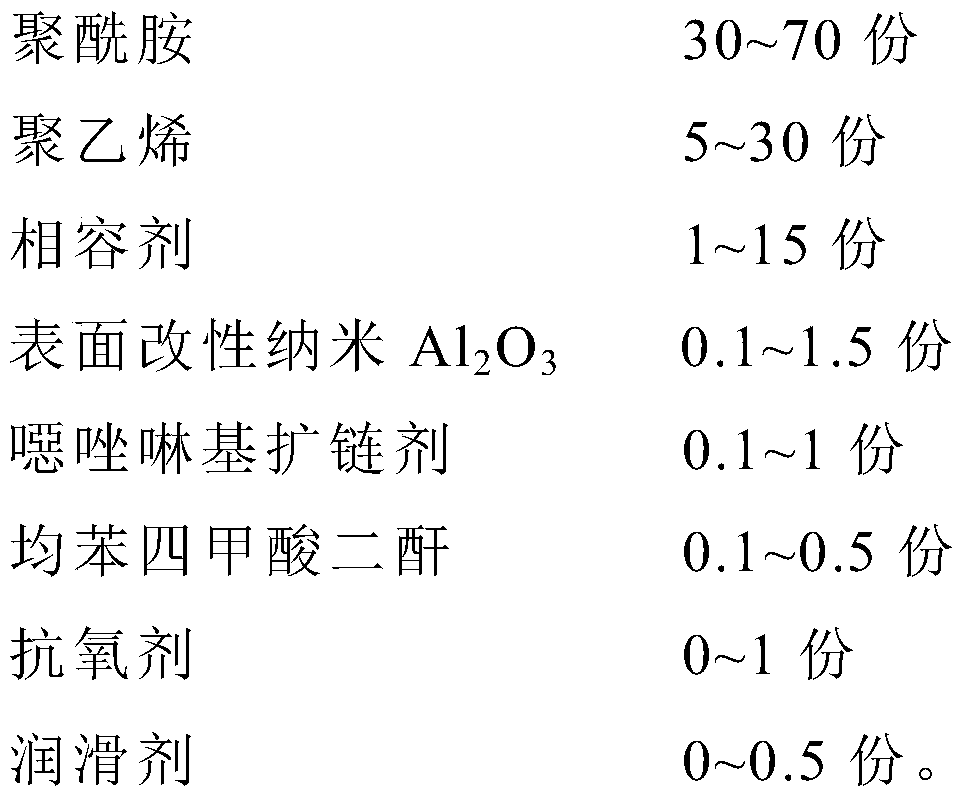

Method used

Image

Examples

Embodiment 1

[0043] The PA / PE blended gold of this embodiment is formed from the following components by weight: 70 parts of PA6, 30 parts of LDPE, 5 parts of SBS-g-MAH, and 0.5 parts of surface-modified nano-Al 2 O 3 , 0.3 part of 1,3-PBO, 0.1 part of PMDA, 0.1 part of antioxidant 1098 and 0.1 part of antioxidant 626, 0.2 part of N,N'-ethylene bis-stearamide.

[0044] Surface Modified Nano-Al 2 O 3 Prepared by the following steps: nano-Al with a particle size range of 30-60nm 2 O 3Add to ethanol solution (80% v / v), ultrasonically treat for 30min; adjust the pH of the mixture to 4.0, add KH-550, stir at high speed for 15min, then heat up to 80°C, react at constant temperature for 30min, centrifuge, wash, and dry to obtain amino Modified Nano-Al 2 O 3 . It has been determined that the amino-modified nano-Al 2 O 3 The grafting rate is 8%.

[0045] 70 parts of PA6, 30 parts of LDPE, 5 parts of SBS-g-MAH, 0.5 parts of surface modified nano-Al 2 O 3 , 0.3 part of 1,3-PBO, 0.1 part o...

Embodiment 2

[0047] The difference between Example 2 and Example 1 is only that: Example 2 uses HDPE instead of LDPE, and other aspects are the same as Example 1.

Embodiment 3

[0049] The only difference between Example 3 and Example 2 is: Example 3 adds 0.3 parts of surface-modified nano-Al 2 O 3 , and others are the same as in Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size range | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com