H13 matrix steel and preparation method thereof

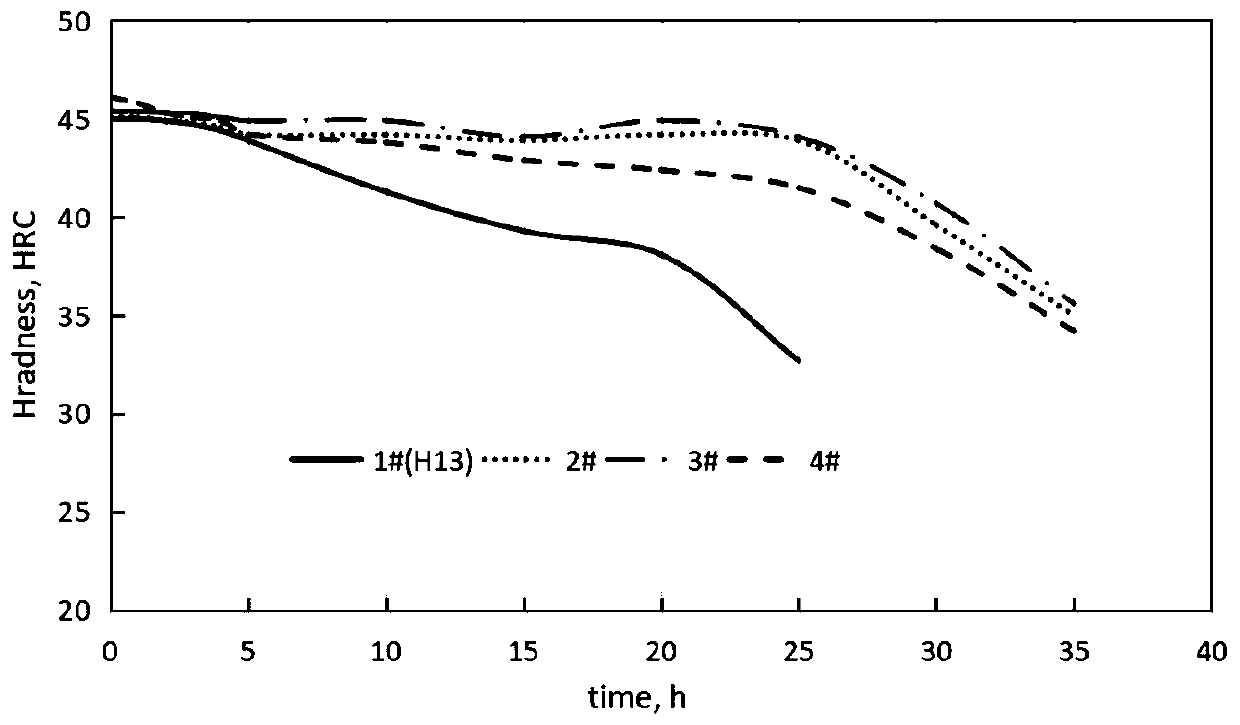

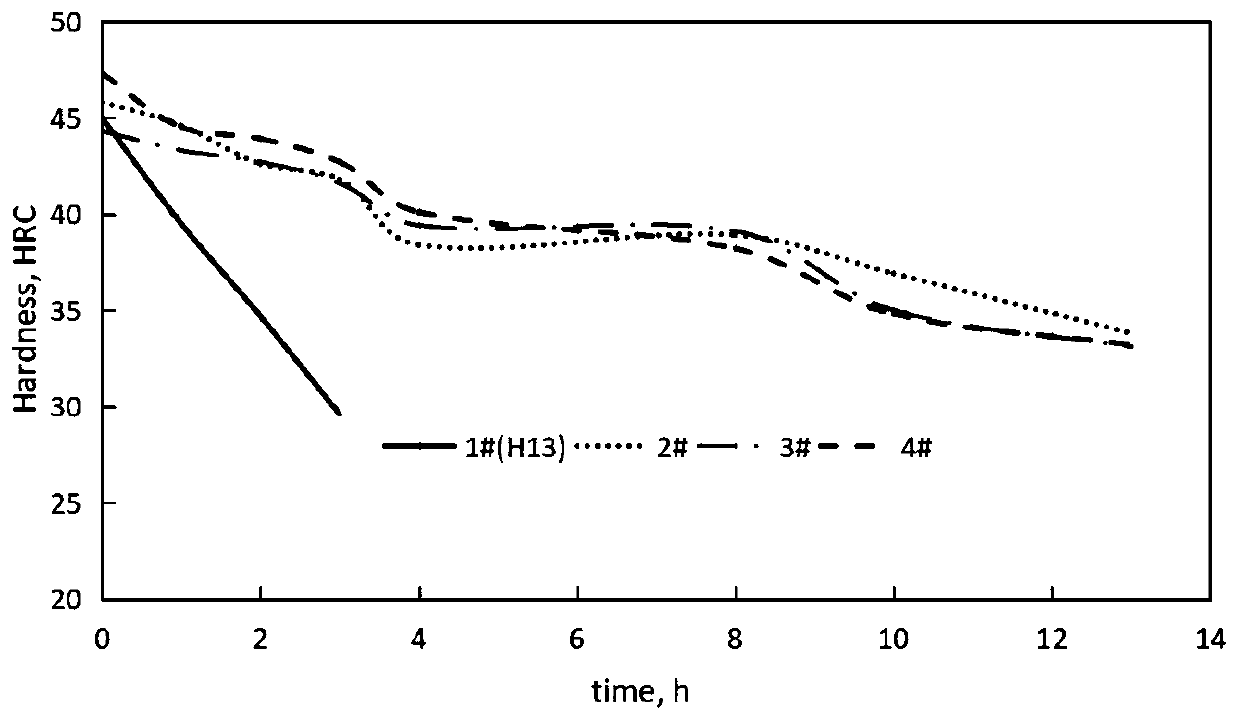

A base steel and base technology, applied in the field of material processing, can solve the problems of poor thermal stability, poor fatigue resistance, low strength and toughness, etc., and achieve the effects of improving thermal stability, prolonging mold life, and improving solid solution strengthening.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0059] In another aspect, the present invention provides a method for preparing H13 matrix steel, comprising the steps of:

[0060] Step 1: According to the composition of each element of the H13 matrix steel, the raw materials are prepared, and the steel ingot is obtained by smelting in a vacuum furnace;

[0061] Step 2: Free forging of the steel ingot;

[0062] The steel ingot forging process is carried out at 1180°C to 1200°C, and the final forging temperature is ≥850°C. Steel ingot free forging adopts three-way forging process for forging. Among them, the three-way forging process is: (1) length and width of steel ingot interchangeable; (2) Z-direction upsetting of steel ingot; (3) X-direction upsetting of steel ingot; (4) Y-direction upsetting of steel ingot; (5) rounding of steel ingot Formed into round rods of specified specifications. Among them, the steel ingot is first forged into a square shape, and then forged by a three-way forging process, the X and Y directio...

Embodiment 1

[0070] The chemical composition and mass percentage of H13 matrix steel 2# are: C: 0.37%; Si: 1.5%; Mn: 0.56%; Cr: 3.1%; Mo: 3.00%; V: 1.00%; Al: 0.001%; N : 0.004%.

[0071] The preparation method of H13 matrix steel 2#, comprises the steps:

[0072] Step 1: According to the composition of each element of the H13 matrix steel, the raw materials are prepared, and the steel ingot is obtained by smelting in a vacuum furnace;

[0073]Step 2: The steel ingot is free forged; the heating temperature of the steel ingot forging is 1180°C, and the final forging temperature is 870°C. First, the steel ingot is forged into a square shape, and forged by a three-way forging process. The three-way forging process is: (1) the length and width of the steel ingot are exchanged; (2) the Z-direction upsetting of the steel ingot; (3) the X-direction upsetting of the steel ingot; (4) the Y-direction upsetting of the steel ingot; (5) the rounding of the steel ingot round stick.

[0074] Step 3...

Embodiment 2

[0077] The chemical composition and mass percentage of H13 matrix steel 3# are: C: 0.37%; Si: 1.0%; Mn: 0.56%; Cr: 3.1%; Mo: 3.00%; V: 1.00%; Al: 0.01%; N : 0.02%.

[0078] The preparation method of H13 matrix steel 3#, comprises the steps:

[0079] Step 1: According to the composition of each element of the H13 matrix steel, the raw materials are prepared, and the steel ingot is obtained by smelting in a vacuum furnace;

[0080] Step 2: The steel ingot is free forged after annealing; the heating temperature of the steel ingot forging is 1200°C, and the final forging temperature is 900°C. First, the steel ingot is forged into a square shape, and forged by a three-way forging process. The three-way forging process is: (1) the length and width of the steel ingot are interchanged; (2) the steel ingot is upset in the Z direction; (3) the steel ingot is upset in the X direction; (4) the steel ingot is upset in the Y direction; (5) the steel ingot is rounded into A round bar with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Brinell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com