Preparation method of antibacterial polyester fiber

A polyester fiber and nanotube technology, applied in the field of textile processing, can solve the problems of accumulated bacteria and odor, poor air permeability, poor hygroscopicity, etc., and achieve the effects of strong binding force, enhanced antibacterial performance, and increased specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

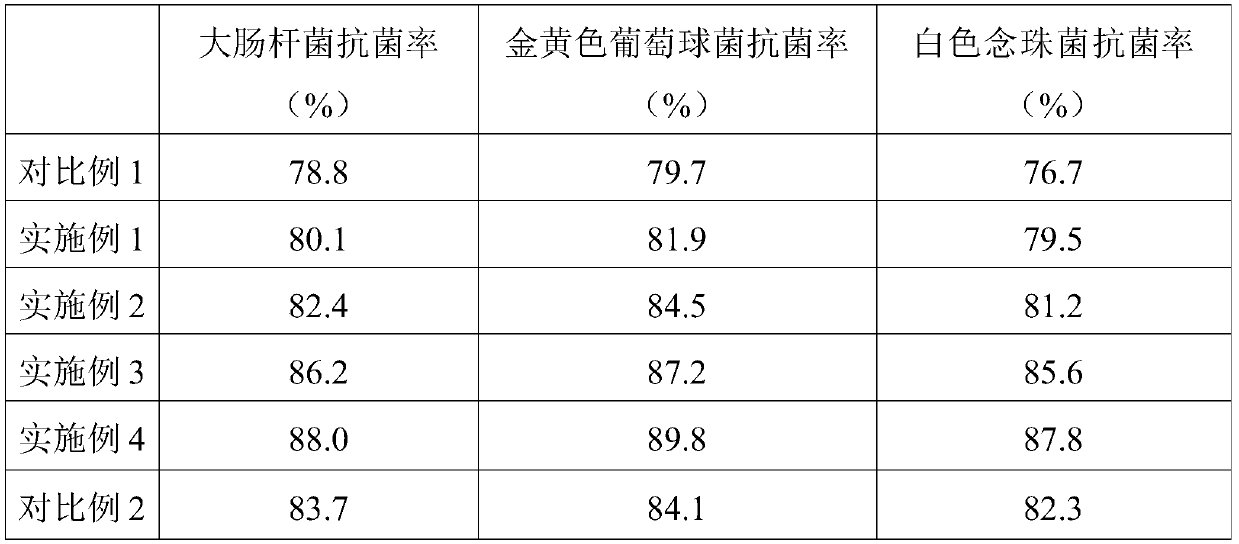

Examples

Embodiment 1

[0040] The antibacterial polyester fiber is prepared by the following method:

[0041] (1) Mix hexamethylene diisocyanate and triethylenediamine at a volume ratio of 95:5 to obtain a mixed solution. Polyester chips and the mixed solution are mixed at a solid-to-liquid ratio of 1g:8mL, soaked at 25°C for 3 hours, and used 200 Filter through a mesh filter cloth, mix the filter cake and deionized water at a solid-to-liquid ratio of 1g: 8mL, soak at 25°C for 3 hours, filter, and dry the filter cake at 50°C to constant weight to obtain pretreated polyester chips;

[0042] (2) 100 parts of pretreated polyester chips, 6 parts of kaolin, 6 parts of medical stone powder, 0.5 parts of modified carbon nanotubes, 1 part of γ-aminopropyltriethoxysilane, and 1 part of polyethylene wax are mixed, Stirring at 600 rpm for 30 minutes, drying at 50°C for 6 hours to obtain a mixture;

[0043] (3) Melt and extrude the mixed material through a twin-screw extruder, spray through a spinneret for spi...

Embodiment 2

[0046] The antibacterial polyester fiber is prepared by the following method:

[0047] (1) Mix hexamethylene diisocyanate and triethylenediamine at a volume ratio of 95:5 to obtain a mixed solution. Polyester chips and the mixed solution are mixed at a solid-to-liquid ratio of 1g:8mL, soaked at 25°C for 3 hours, and used 200 Filter through a mesh filter cloth, mix the filter cake and deionized water at a solid-to-liquid ratio of 1g: 8mL, soak at 25°C for 3 hours, filter, and dry the filter cake at 50°C to constant weight to obtain pretreated polyester chips;

[0048] (2) 100 parts of pretreated polyester chips, 6 parts of kaolin, 6 parts of medical stone powder, 0.5 parts of modified carbon nanotubes, 1 part of γ-aminopropyltriethoxysilane, and 1 part of polyethylene wax are mixed, Stirring at 600 rpm for 30 minutes, drying at 50°C for 6 hours to obtain a mixture;

[0049] (3) Melt and extrude the mixed material through a twin-screw extruder, spray through a spinneret for spi...

Embodiment 3

[0052] The antibacterial polyester fiber is prepared by the following method:

[0053] (1) Mix hexamethylene diisocyanate and triethylenediamine at a volume ratio of 95:5 to obtain a mixed solution. Polyester chips and the mixed solution are mixed at a solid-to-liquid ratio of 1g:8mL, soaked at 25°C for 3 hours, and used 200 Filter through a mesh filter cloth, mix the filter cake and deionized water at a solid-to-liquid ratio of 1g: 8mL, soak at 25°C for 3 hours, filter, and dry the filter cake at 50°C to constant weight to obtain pretreated polyester chips;

[0054] (2) 100 parts of pretreated polyester chips, 6 parts of kaolin, 6 parts of medical stone powder, 0.5 parts of modified carbon nanotubes, 1 part of γ-aminopropyltriethoxysilane, and 1 part of polyethylene wax are mixed, Stirring at 600 rpm for 30 minutes, drying at 50°C for 6 hours to obtain a mixture;

[0055] (3) Melt and extrude the mixed material through a twin-screw extruder, spray through a spinneret for spi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com