Durable type ultraviolet-radiation-resistant curtain fabric and production method thereof

A manufacturing method, anti-ultraviolet technology, applied in the field of curtain fabrics, to achieve the effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

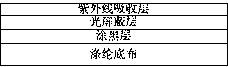

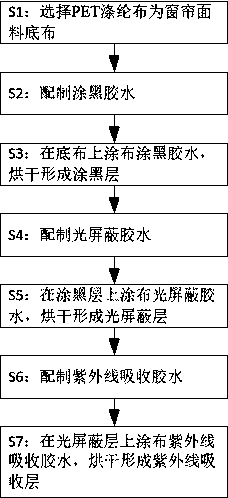

Image

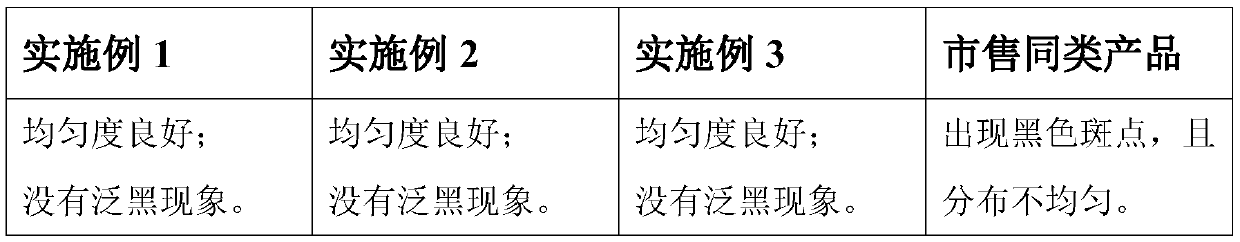

Examples

Embodiment 1

[0041] S1. Choose PET polyester fabric as the base fabric of the curtain fabric; its specification adopts 150D*300D;

[0042] S2, prepare blackened glue, its preparation process is as follows:

[0043] Quantitatively weigh 60 parts by weight of acrylic resin emulsion with a solid content of 45%, 20 parts of talcum powder and 5 parts of carbon black slurry, mix them and stir evenly, and add a thickener during the stirring process Adjust viscosity to 1.3×10 4 ~1.5×10 4 mPa·s, thereby obtaining blackened glue; Wherein, the mesh number of talcum powder is 1200 mesh;

[0044] S3. Evenly scrape and coat the prepared blackened glue on the base fabric of the curtain fabric, and then obtain a blackened layer after drying; when scraping and coating the blackened glue, the thickness of the coating should be controlled at 20-30 μm, and then dried The hourly drying temperature is 160°C, and the drying time is 35-45 seconds;

[0045] S4, preparing light-shielding glue, the preparation p...

Embodiment 2

[0052] S1. Choose PET polyester fabric as the base fabric of the curtain fabric; its specification adopts 150D*300D;

[0053] S2, prepare blackened glue, its preparation process is as follows:

[0054] Quantitatively weigh 70 parts by weight of acrylic resin emulsion with a solid content of 45%, 25 parts of talcum powder and 10 parts of carbon black slurry, mix them and stir evenly, and add a thickener during the stirring process Adjust viscosity to 1.3×10 4 ~1.5×10 4 mPa·s, thereby obtaining blackened glue; Wherein, the mesh number of talcum powder is 1200 mesh;

[0055] S3. Evenly scrape and coat the prepared blackened glue on the base fabric of the curtain fabric, and then obtain a blackened layer after drying; when scraping and coating the blackened glue, the thickness of the coating should be controlled at 20-30 μm, and then dried The hourly drying temperature is 160°C, and the drying time is 35-45 seconds;

[0056] S4, preparing light-shielding glue, the preparation ...

Embodiment 3

[0063] S1. Choose PET polyester fabric as the base fabric of the curtain fabric; its specification adopts 150D*300D;

[0064] S2, prepare blackened glue, its preparation process is as follows:

[0065] Quantitatively weigh 65 parts by weight of acrylic resin emulsion with a solid content of 45%, 23 parts of talcum powder and 8 parts of carbon black slurry, mix them and stir evenly, and add a thickener during the stirring process Adjust viscosity to 1.3×10 4 ~1.5×10 4 mPa·s, thereby obtaining blackened glue; Wherein, the mesh number of talcum powder is 1200 mesh;

[0066] S3. Evenly scrape and coat the prepared blackened glue on the base fabric of the curtain fabric, and then obtain a blackened layer after drying; when scraping and coating the blackened glue, the thickness of the coating should be controlled at 20-30 μm, and then dried The hourly drying temperature is 160°C, and the drying time is 35-45 seconds;

[0067] S4, preparing light-shielding glue, the preparation p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com