MXene-based flexible self-supporting electrode material and preparation method thereof

An electrode material, base electrode technology, applied in the direction of active material electrode, positive electrode, battery electrode, etc., can solve the problems of cumbersome preparation method, unfavorable electrochemical performance of material, limited conductivity of polymer film layer, etc., to improve the utilization rate , Improve long-term cycle stability, inhibit the effect of dissolution behavior

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] (1) Preparation of positive electrode sheet

[0038] With NTCDA and / or NDI as the active material, carbon black as the conductive agent, and polyvinylidene chloride (PVDF) as the binder, according to the mass fraction ratio, the ratio of active material: binder: conductive agent = 6:3:1 , fully ground and mixed evenly to form a slurry, which was poured onto copper foil with a scraper and dried overnight in a vacuum oven at 100°C, then rolled into a positive electrode sheet with a diameter of 10mm.

[0039] (2) Assembly of battery

[0040] Adopt CR-2032 button battery case, use the flexible electrode material prepared by the present invention and / or NTCDA and / or NDI as positive pole, metal lithium as negative pole, CelgardM825 microporous membrane as diaphragm, 1M LiPF 6 / EC+DMC (1:1, v / v) is the electrolyte, and in a glove box filled with argon, assemble it into a button battery in a certain order.

[0041] (3) Charge and discharge test

[0042] The present invention...

Embodiment 1

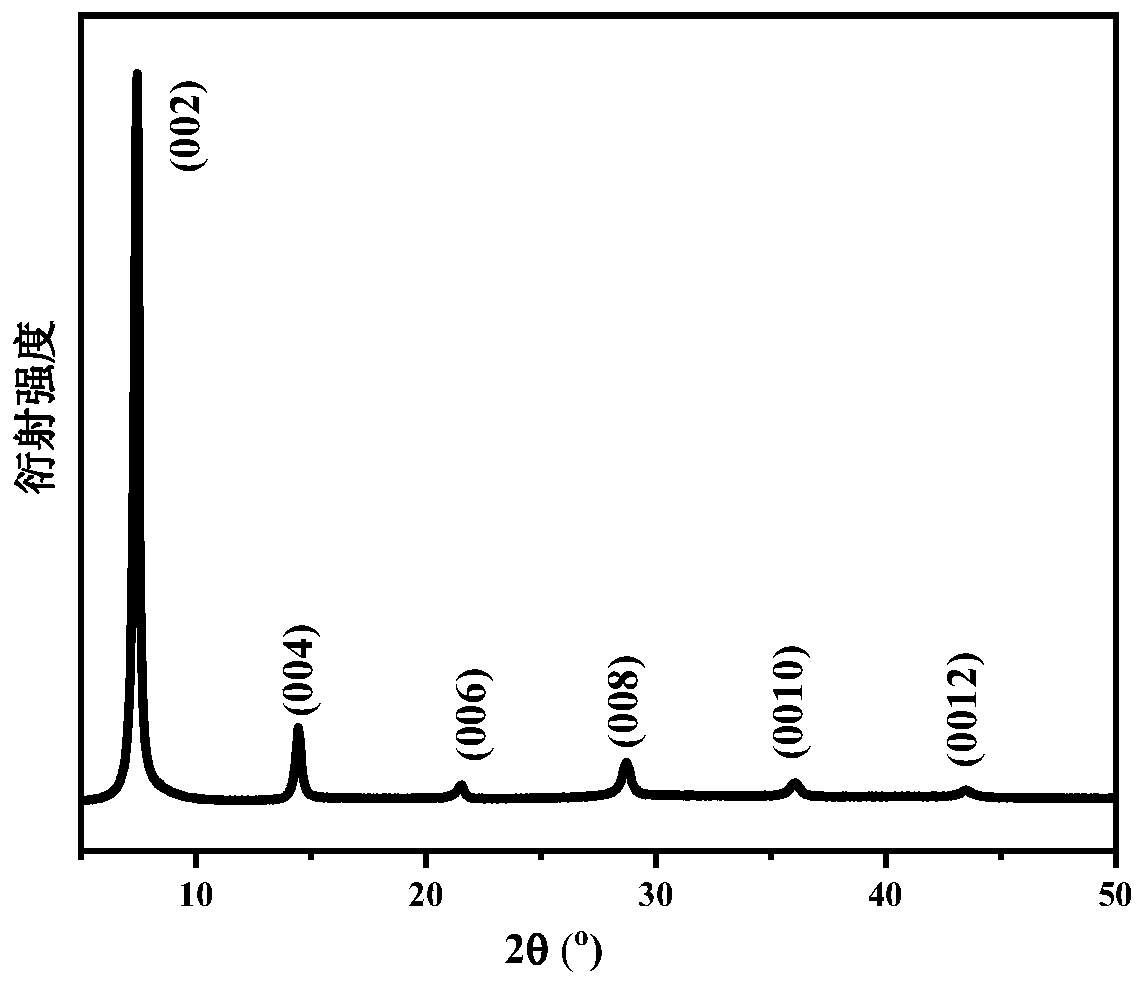

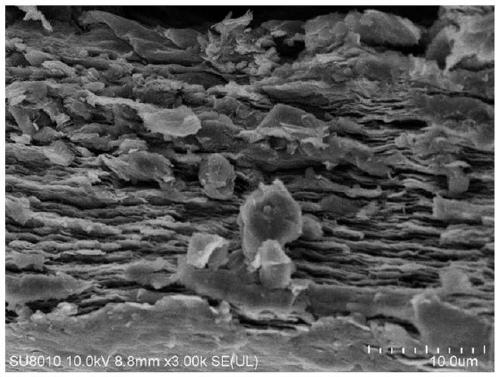

[0044] (1) Prepare MXene dispersion with a concentration of 5 mg / mL.

[0045] Prepare the etching solution of LiF, hydrochloric acid and ultrapure water and stir well, then add MAX phase Ti 3 AlC 2 The powder was continuously stirred and reacted. After the etching was completed, the mixed solution was transferred to a centrifuge tube, and centrifuged several times until the pH of the supernatant was close to 7; then the obtained precipitate was fully dispersed in deionized water, and the upper black dispersion was collected by centrifugation again, and finally Store the dispersion at low temperature.

[0046](2) Under the protection of high-purity argon and in a 25mL three-neck flask with a gas guide plug, add 25mg of NTCDA and 5mL of deionized water into the flask respectively, and ultrasonically treat it for 20min to make it evenly dispersed, and the mass ratio of NTCDA is controlled 50%.

[0047] (3) Under the protection of high-purity argon, pipette 5 mL of MXene disper...

Embodiment 2

[0059] (1) Prepare MXene dispersion with a concentration of 5 mg / mL.

[0060] Prepare the etching solution of LiF, hydrochloric acid and ultrapure water and stir well, then add MAX phase Ti 3 AlC 2 The powder was continuously stirred and reacted. After the etching was completed, the mixed solution was transferred to a centrifuge tube, and centrifuged several times until the pH of the supernatant was close to 7; then the obtained precipitate was fully dispersed in deionized water, and the upper black dispersion was collected by centrifugation again, and finally Store the dispersion at low temperature.

[0061] (2) Under the protection of high-purity argon and in a 25mL three-neck flask with a gas guide plug, add 30mg of NTCDA and 6mL of deionized water into the flask respectively, and ultrasonically treat it for 20min to make it evenly dispersed, and the mass ratio of NTCDA is controlled 60%.

[0062] (3) Under the protection of high-purity argon, pipette 4mL of MXene disper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com