Immobilized tungsten trioxide nanosheet array as well as preparation method and application thereof

A nanosheet array, tungsten trioxide technology, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, chemical/physical processes, etc., to achieve good crystallinity, strong operability, and size distribution uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

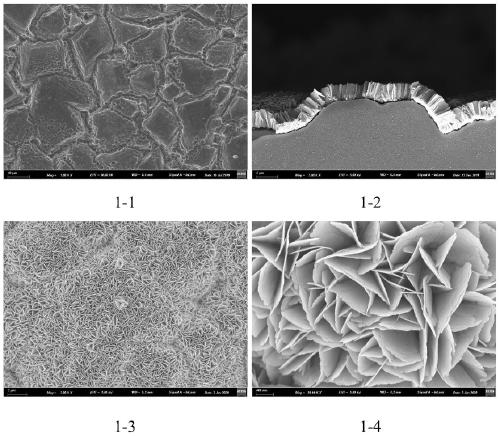

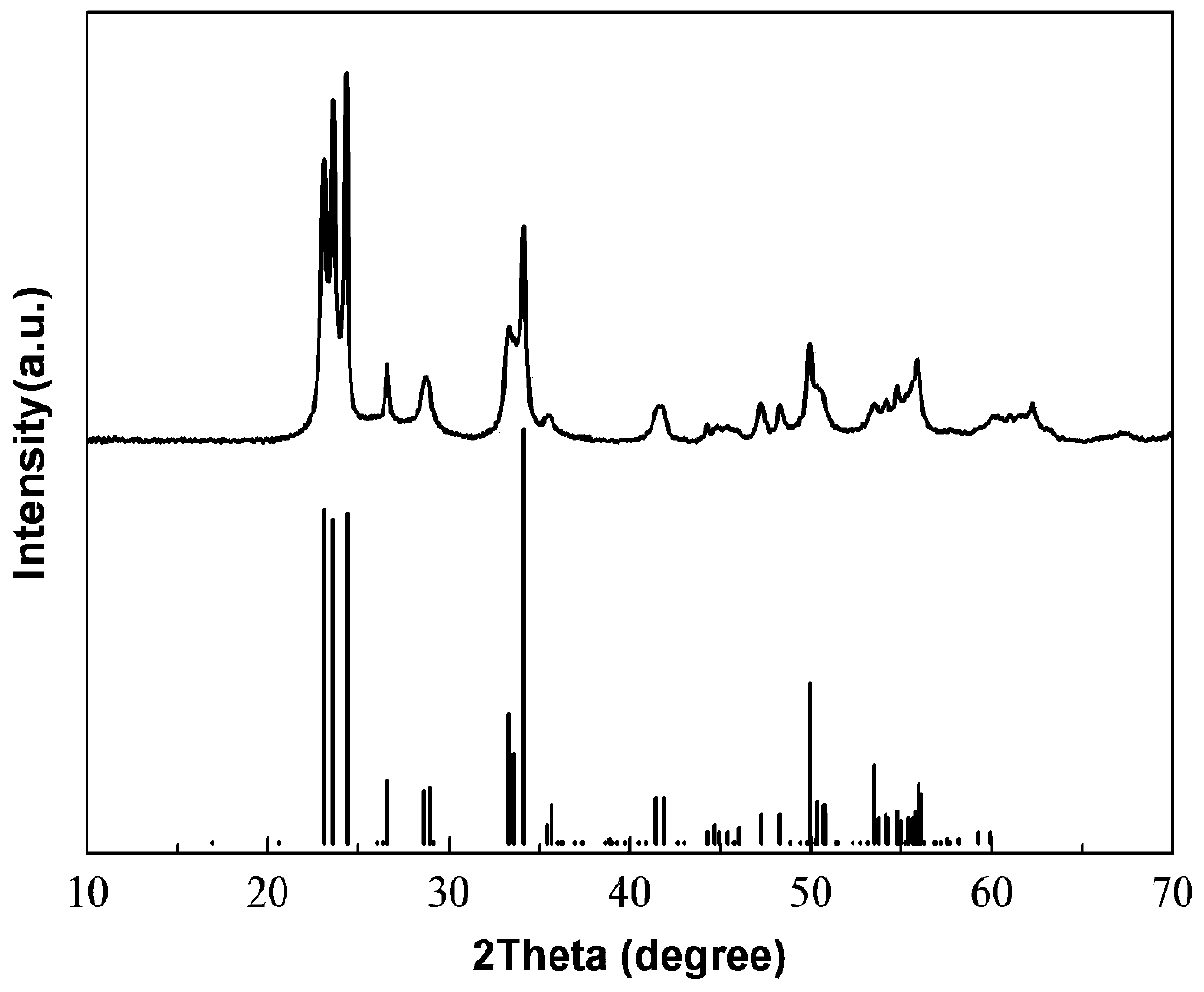

[0041] Weigh 0.793g WCl 6 The powder was dissolved in 50ml of n-propanol, placed on a magnetic stirrer with a rotation speed of 350rpm, and stirred for 80min in an air atmosphere to fully dissolve, and a precursor solution with a concentration of 0.04mol / L was obtained.

[0042] Take one-sided frosted glass, and ultrasonically clean it with acetone, absolute ethanol, and deionized water for 15 minutes in sequence. After cleaning and drying, the rough frosted surface faces downward at 45°, and put it in a 100mL polytetrafluoroethylene liner, and then add the precursor solution Transfer to the lining, seal the reaction kettle and keep it warm at 200°C for 12h. After the reaction, cool down to room temperature naturally, take out the immobilized product and place it in a drying oven, and dry it at 60°C for 10-12h under atmospheric pressure to obtain the raw material on the glass frosted surface. In-situ grown tungsten trioxide nanosheet arrays.

[0043] Take the single-sided fro...

Embodiment 2

[0049] Weigh 1.190g WCl 6 The powder was dissolved in 50ml of n-propanol, placed on a magnetic stirrer with a rotation speed of 350rpm, and stirred for 80min in an air atmosphere to fully dissolve it to obtain a precursor solution with a concentration of 0.06mol / L.

[0050] Take one-sided frosted glass, and ultrasonically clean it with acetone, absolute ethanol, and deionized water for 15 minutes in sequence. After cleaning and drying, the rough frosted surface faces downward at 45°, and put it in a 100mL polytetrafluoroethylene liner, and then add the precursor solution Transfer to the lining, seal the reaction kettle and keep it warm at 200°C for 12h. After the reaction, cool down to room temperature naturally, take out the immobilized product and place it in a drying oven, and dry it at 60°C for 10-12h under atmospheric pressure to obtain the raw material on the glass frosted surface. In-situ grown tungsten trioxide nanosheet arrays.

Embodiment 3

[0052] Weigh 1.586g WCl 6 The powder was dissolved in 50ml of n-propanol, placed on a magnetic stirrer with a rotation speed of 350rpm, and stirred for 80min in an air atmosphere to fully dissolve it to obtain a precursor solution with a concentration of 0.08mol / L.

[0053] Take one-sided frosted glass, and ultrasonically clean it with acetone, absolute ethanol, and deionized water for 15 minutes in sequence. After cleaning and drying, the rough frosted surface faces downward at 45°, and put it in a 100mL polytetrafluoroethylene liner, and then add the precursor solution Transfer to the lining, seal the reaction kettle and keep it warm at 200°C for 12h. After the reaction, cool down to room temperature naturally, take out the immobilized product and place it in a drying oven, and dry it at 60°C for 10-12h under atmospheric pressure to obtain the raw material on the glass frosted surface. In-situ grown tungsten trioxide nanosheet arrays.

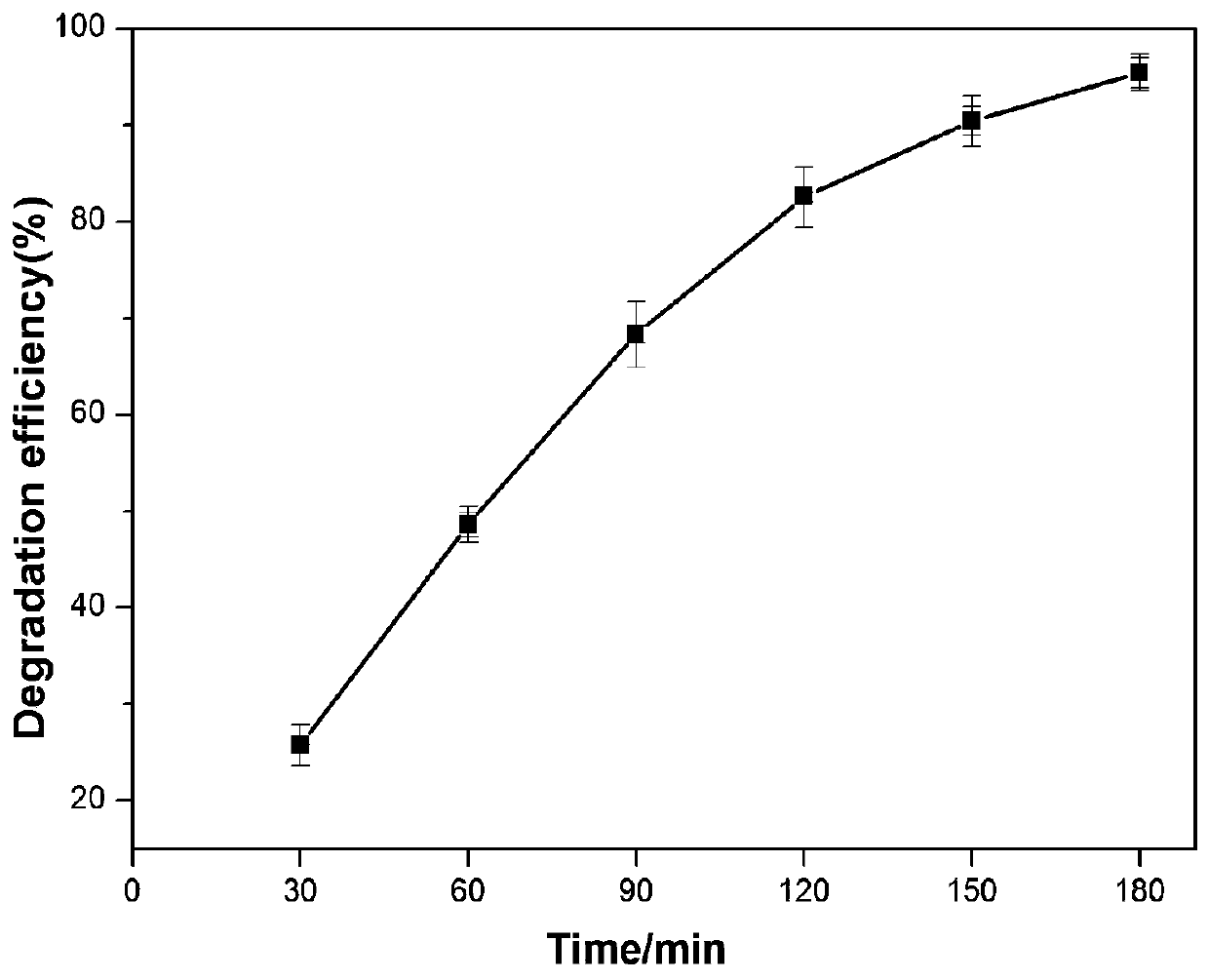

[0054] Simulating visible light irrad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com