Forming process for polyester fiber spun yarns

A technology of polyester fiber and molding process, which is applied in the direction of filament/thread molding, single-component polyester artificial filament, fiber treatment, etc., and can solve the problem of insufficient strength of spinning structure, easy occurrence of broken filaments, and easy broken filaments, etc. problems, to achieve the effect of improving spinning quality, reducing thread breakage and enhancing spinning toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

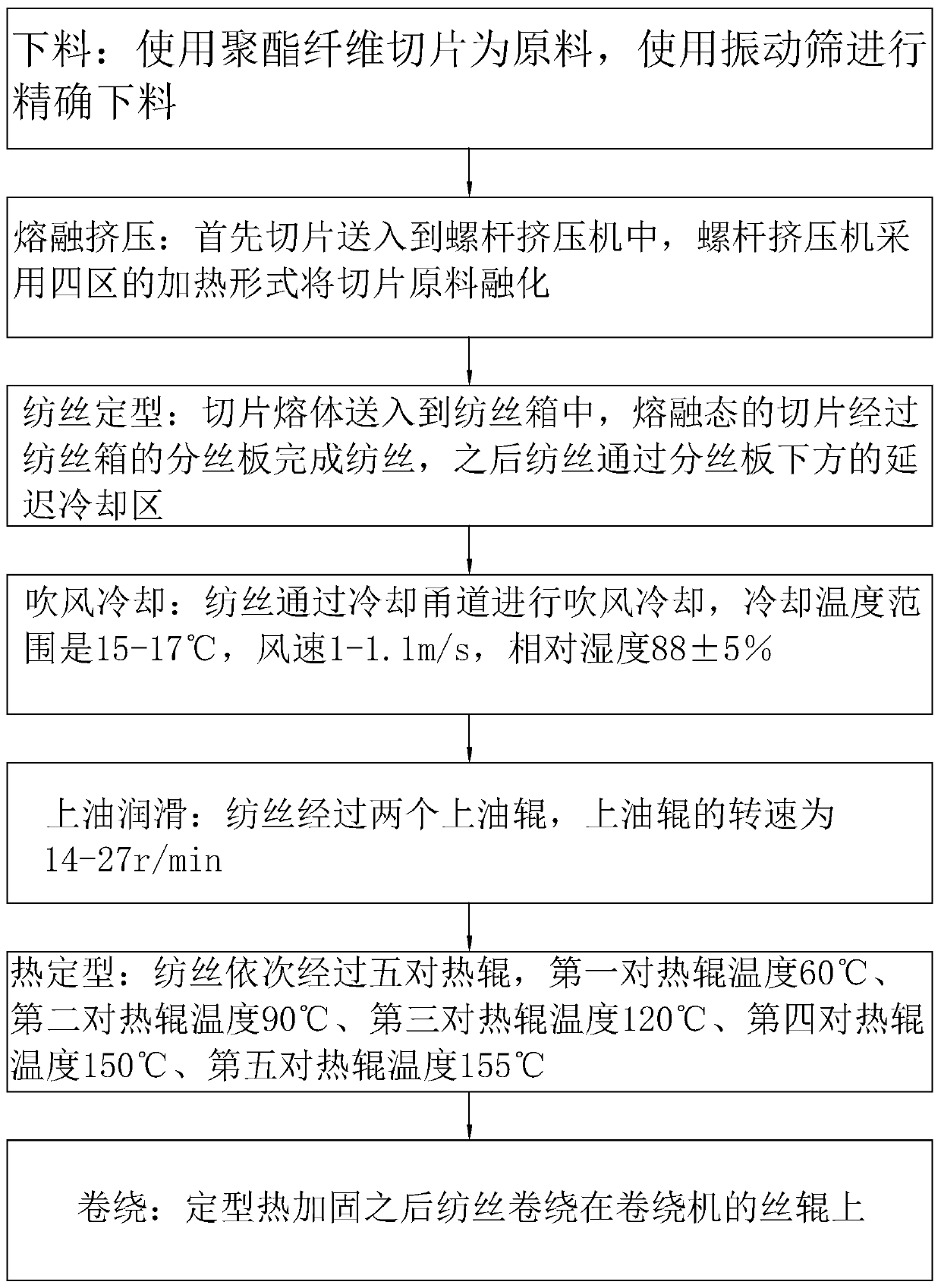

[0026] Embodiment 1: a kind of molding process of polyester fiber spinning, such as figure 1 shown, including the following steps:

[0027] S1. Blanking: Use polyester fiber slices as raw materials, and use a vibrating screen for precise cutting.

[0028] S2. Cutting material: melt extrusion: firstly, the slices are fed into the screw extruder, the screw of the screw extruder is sprayed with 1-1.5mm chromium alloy coating, and the inner wall of the screw sleeve is sprayed with 1.5-2mm The chromium alloy cladding layer, the screw extruder shell is arranged with at least 6mm rear insulation cotton insulation layer. When working, the inner wall of the screw rod and the screw sleeve is evenly in contact with the slice melt, so a chromium alloy coating is set to protect the screw rod and the screw sleeve.

[0029] The screw extruder adopts the heating mode of four zones to melt the sliced raw materials. The temperature of heating zone I is 220°C, the temperature of heating zone...

Embodiment 2

[0042] Embodiment 2: the steps different from Embodiment 1 are:

[0043] S2: The temperature of heating zone I is 223°C, the temperature of heating zone II is 232°C, the temperature of heating zone III is 243°C, and the temperature of heating zone IV is 253°C.

Embodiment 3

[0044] Embodiment 3: the steps different from Embodiment 1 are:

[0045] S2: The temperature of heating zone I is 225°C, the temperature of heating zone II is 235°C, the temperature of heating zone III is 245°C, and the temperature of heating zone IV is 255°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com