Preparation method for crossed special-shaped skin-core moisture absorption and removal fiber

A technology of skin-core fiber and wet fiber, which is applied in the field of preparation of cross-shaped skin-core moisture-absorbing and dehumidifying fibers, which can solve the problems of increasing the weight of clothes, stuffy and uncomfortable, hindering sweat evaporation and skin heat dissipation, etc., to increase the contact area and increase the specific surface area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] A method for preparing a cross-shaped sheath-core moisture-absorbing and dehumidifying fiber, comprising the following steps:

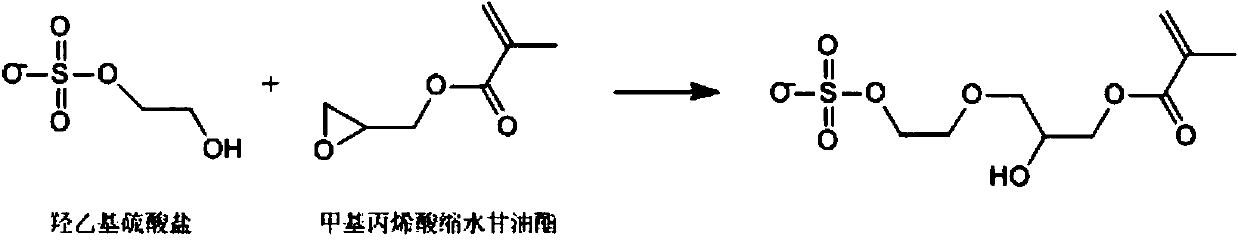

[0041] 1) Use titanium series composite catalysts for terephthalic acid, ethylene glycol, the third monomer ethylene glycol isophthalate sulfonate, the fourth monomer polyethylene glycol, and environment-friendly polyester (applicant's prior The catalyst described in Example 1 in the application CN201811059731.8) is blended for esterification reaction. The reaction process conditions are: temperature 240-250°C, time 2-3h, pressure ≤ 0.3MPa, and obtain a prepolymer after esterification; then The polycondensation reaction is carried out at a vacuum degree of 0-100 Pa, the temperature is 270-290° C., and the time is 3-4 hours. After the reaction is completed, the material is discharged, dried, and pelletized to obtain a cotton-like polyester chip A. The molar ratio of the terephthalic acid, ethylene glycol and the third monomer ethylene glycol sul...

Embodiment 1

[0050] A method for preparing a cross-shaped sheath-core moisture-absorbing and dehumidifying fiber, comprising the following steps:

[0051] 1) Combine terephthalic acid (PTA), ethylene glycol (EG), the third monomer ethylene glycol sulfonate isophthalate (SIPE), the fourth monomer polyethylene glycol (PEG) and environmental protection A titanium-based composite catalyst for polyester-type polyester is put into the polyester reactor together, and the esterification reaction is carried out at 240 ° C and the pressure is lower than 0.3 MPa for 3 hours to obtain a prepolymer, wherein the molar ratio of PTA: EG: SIPE is 1: 1.3:0.03, the mass ratio of PEG to PTA is 0.01:1, the mass ratio of catalyst to PTA is 0.003%:1; then polycondensation reaction is carried out under a vacuum lower than 100Pa, the temperature is 270°C, and the time is 3h. The hydrophilic cotton-like polyester chip A is prepared after drying and pelletizing;

[0052] 2) Pass the polyvinylpyrrolidone of the cott...

Embodiment 2

[0057] A method for preparing a cross-shaped sheath-core moisture-absorbing and dehumidifying fiber, comprising the following steps:

[0058] 1) Combine terephthalic acid (PTA), ethylene glycol (EG), the third monomer ethylene glycol sulfonate isophthalate (SIPE), the fourth monomer polyethylene glycol (PEG) and environmental protection A titanium-based composite catalyst for polyester-type polyester is put into the polyester reactor together, and the esterification reaction is carried out at 240 ° C and the pressure is lower than 0.3 MPa for 3 hours to obtain a prepolymer, wherein the molar ratio of PTA: EG: SIPE is 1: 1.3:0.03, the mass ratio of PEG to PTA is 0.01:1, the mass ratio of catalyst to PTA is 0.003%:1; then polycondensation reaction is carried out under a vacuum lower than 100Pa, the temperature is 270°C, and the time is 3h. The hydrophilic cotton-like polyester chip A is prepared after drying and pelletizing;

[0059] 2) Pass the polyvinylpyrrolidone of the imit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com