Organosilicon emulsion defoamer and preparation method thereof

A technology of silicone emulsion and defoamer, applied in the field of defoamer, can solve the problems of reduced production efficiency, slow defoaming efficiency, increased production steps, etc., and achieve the effects of improving production efficiency, reducing stirring steps, and improving dispersion speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The invention provides a silicone emulsion defoamer, in proportion, the defoamer is prepared from the following materials:

[0032] 30% silicone oil, 10% stabilizer, 45% water, 3% dispersant, 6% liquid carbon dioxide and 6% catalyst.

[0033] Wherein, the silicone oil is methyl silicone oil, and the telomerization ratio between the preparation raw material ring body, the head agent and the catalyst in the silicone oil is 1:0.5:0.2.

[0034] Wherein, the stabilizer is preferably perchlorate.

[0035] Among them, the catalyst is preferably a liquid catalyst.

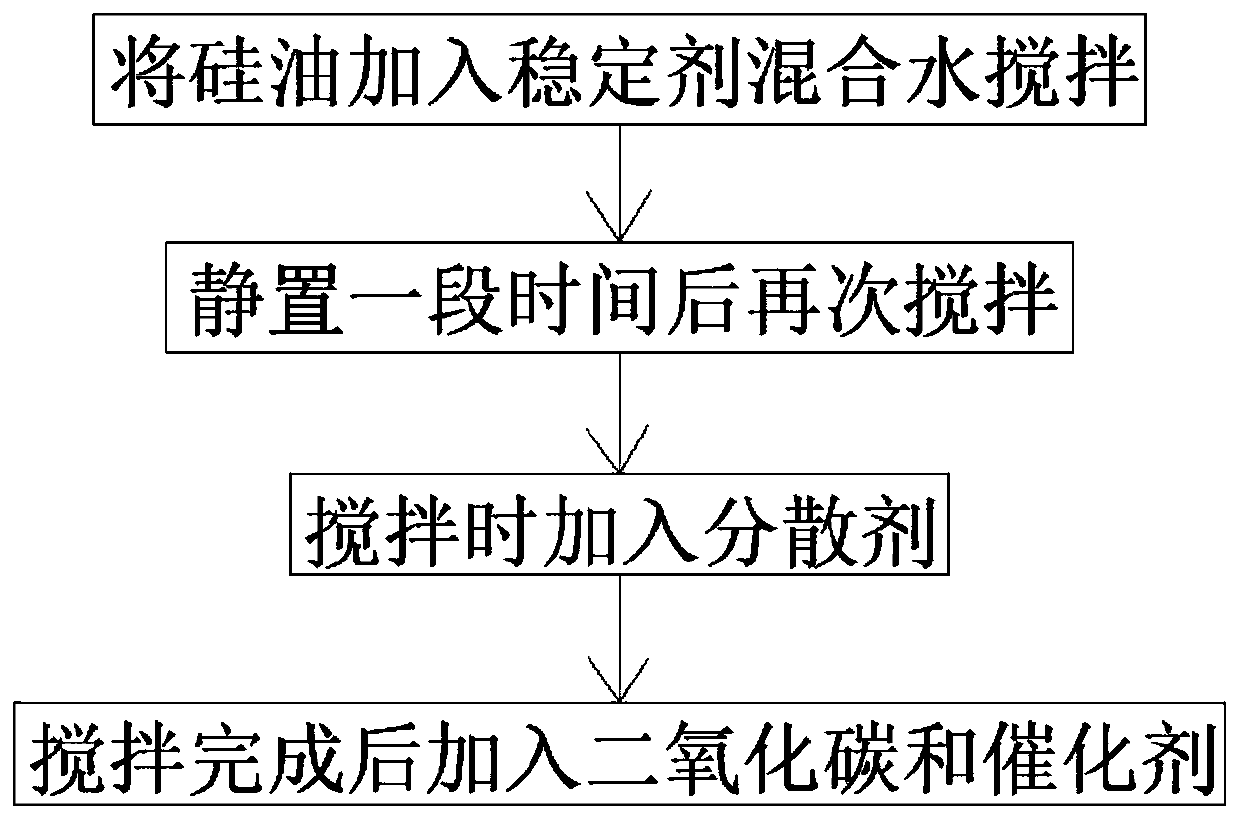

[0036] A kind of preparation method of organosilicon emulsion defoamer, the preparation method of this defoamer is as follows:

[0037] Step 1: Stir the silicone oil with stabilizer and water for 90 minutes;

[0038] Step 2: After the stirring is completed, let it stand for 2 days, and then stir again;

[0039] Step 3: Add dispersant while stirring, stir at ambient temperature between 45°C and 50°C, and stir for...

Embodiment 2

[0042] The invention provides a silicone emulsion defoamer, which is prepared from the following materials:

[0043] Silicone oil, stabilizer, water, dispersant, liquid carbon dioxide and catalyst.

[0044] As a preferred version of a silicone emulsion defoamer according to the present invention, wherein: in proportion, the defoamer is prepared from the following materials:

[0045] 35% silicone oil, 7% stabilizer, 42% water, 5% dispersant, 8% liquid carbon dioxide and 3% catalyst.

[0046] Wherein, the silicone oil is methyl silicone oil, and the telomerization ratio between the preparation raw material ring body, the head agent and the catalyst in the silicone oil is 1:0.5:0.2.

[0047] Wherein, the stabilizer is preferably hydrotalcite series.

[0048] Among them, the catalyst is preferably a liquid catalyst.

[0049] A kind of preparation method of organosilicon emulsion defoamer, the preparation method of this defoamer is as follows:

[0050] Step 1: Stir the silicone...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com