Loading and unloading control system, loading and unloading equipment and loading and unloading method

A control system and equipment technology, applied in the direction of conveyor control devices, conveyor objects, transportation and packaging, etc., can solve the problems of heavy repetitive labor intensity of operators, omission of gaskets, quality of subsequent processes, and inability to guarantee safe and effective production. Achieve the effects of avoiding gasket omission, improving production safety, and saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

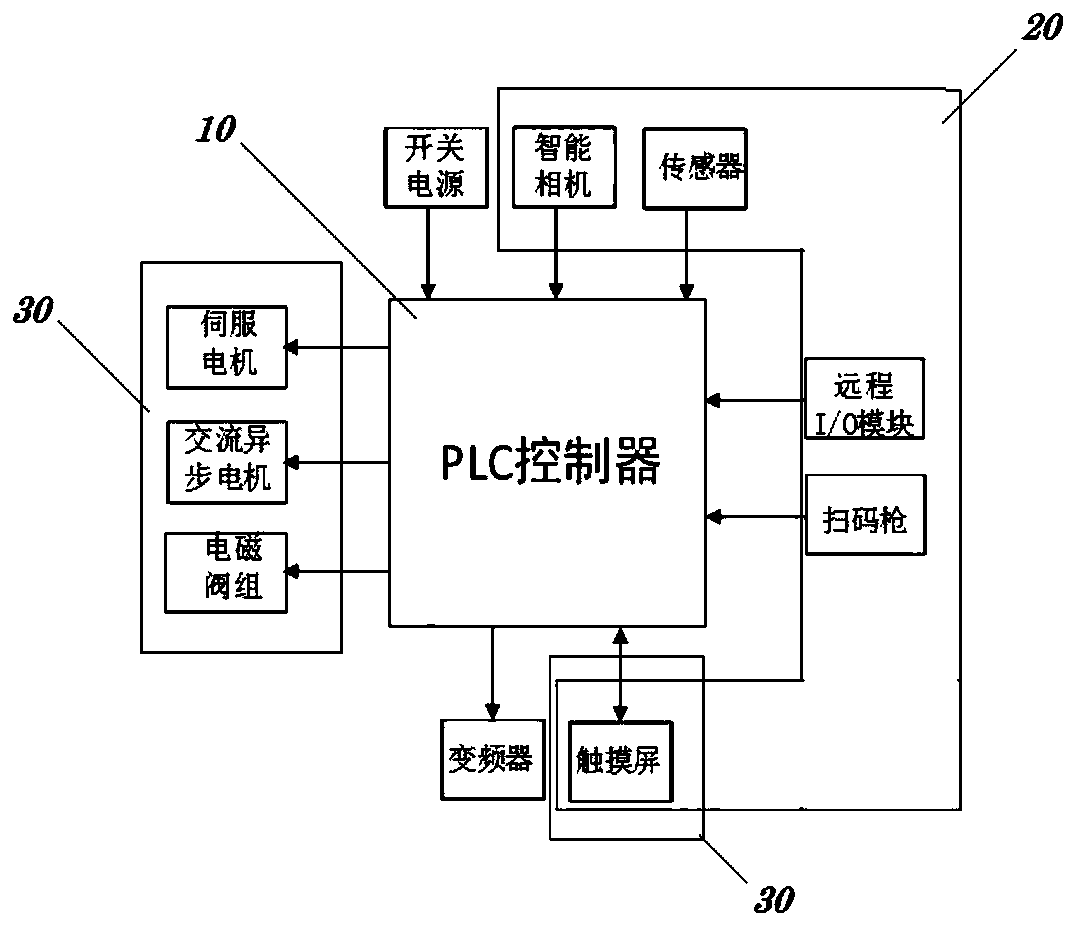

[0055] like figure 1As shown, the loading and unloading control system of this embodiment includes: a controller 10 , an input feedback terminal 20 and an output control terminal 30 . Among them, the input feedback terminal 20 and the controller 10 transmit signals, the controller 10 and the output control terminal 30 perform signal transmission, and the controller 10 receives the feedback signal sent from the input feedback terminal 20 and sends a command signal to the output control terminal 30 .

[0056] As the core unit of the entire control system, the controller 10 receives and processes the signal sent by the input feedback terminal 20, and sends a command signal to the output control terminal 30 for signal transmission based on the received signal, and controls the output control terminal 30 to execute the corresponding action. In one embodiment, the controller 10 may be a PLC controller 10, and the PLC controller 10 may communicate through the Profinet protocol. Spe...

Embodiment 2

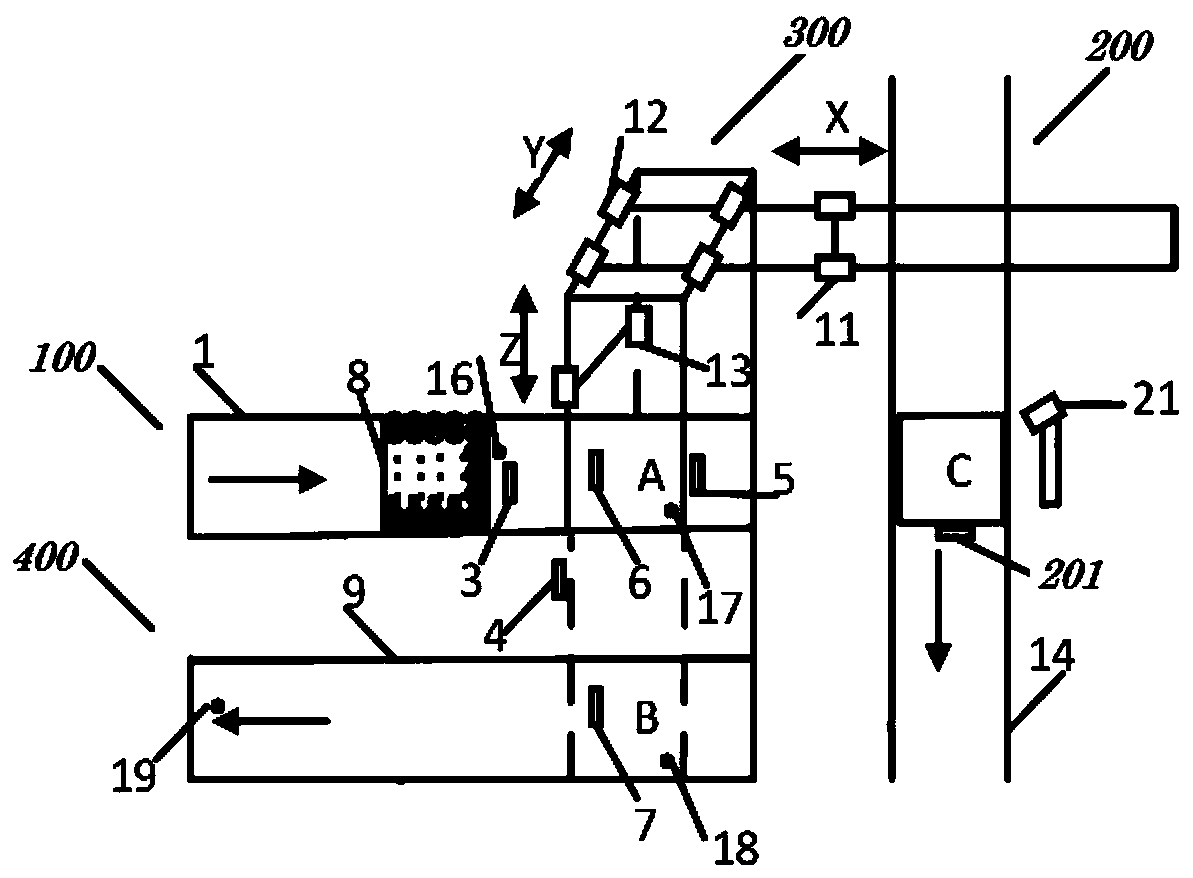

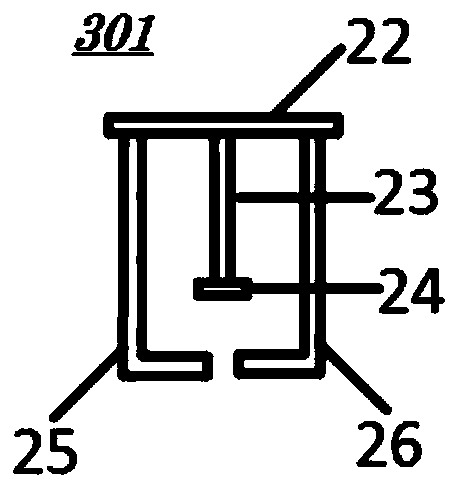

[0069] like figure 2 , 3 As shown, the loading and unloading equipment of this embodiment includes: a feeding conveyor line 100, an assembly line 200, a turnover mechanism 300, and the above-mentioned loading and unloading control system.

[0070] The assembly line 200 is located downstream of the feeding conveyor line 100 , and the turnover mechanism 300 performs reciprocating turnover between the downstream end of the feeding conveyor line 100 and the assembly line 200 under the control of the loading and unloading control system.

[0071] The feeding conveying line 100 is used to realize the feeding of products. Specifically, the feed conveying line 100 includes: a feed conveying belt 1, a first stop cylinder 3, a second stop cylinder 5, and a first jacking cylinder 6;

[0072] The feeding conveyor belt 1 has a buffer station and a feeding station, the first stop cylinder 3 is initially located under the downstream side of the buffer station, and the second stop cylinder...

Embodiment 3

[0099]In this embodiment, the controller is a PLC controller, the touch input and output device is a touch screen, the loading station is at position A, the buffer station is at position B, and the assembly station is at position C.

[0100] The loading and unloading method of the present embodiment comprises the steps:

[0101] Step 1. According to the actual production product model, select the corresponding formula model through the touch screen and download it to the PLC controller;

[0102] Step 2, carry out initialization operation to above-mentioned PLC system;

[0103] Step 3, the above-mentioned PLC judges whether there is an operation request, if not, continues to stand by, if there is an operation request, then detects whether it is an automatic control request, if not an automatic request, then switches to manual mode operation;

[0104] Step 4. If the above-mentioned PLC detection is automatic control, read the barcode / QR code of the recovery valve system provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com